Lamp24

Member

Hey All

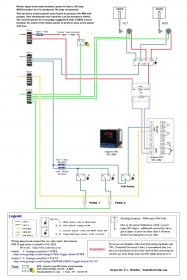

I have been contemplating the idea of building a simple control box to control an eHLT and possibly in the future control a heating element in the boil kettle as well. Right now I think Im going to use the simple set up to have one PID with the temperature probe in the eHLT and possibly run the boil kettle off the manual mode in the future. I have a 60 Amp breaker I can utilize so I was wanting to run a 5500 watt element and possibly two in the future. So with that said I have noticed that a lot of people are utilizing a 40amp SSR could I get by with a 25 amp SSR for a 5500 watt element? Is there a such thing as putting two 25amp SSR in series to equal a 50amp SSR? Im asking because I can get the 25amp SSR for free.

Thanks

I have been contemplating the idea of building a simple control box to control an eHLT and possibly in the future control a heating element in the boil kettle as well. Right now I think Im going to use the simple set up to have one PID with the temperature probe in the eHLT and possibly run the boil kettle off the manual mode in the future. I have a 60 Amp breaker I can utilize so I was wanting to run a 5500 watt element and possibly two in the future. So with that said I have noticed that a lot of people are utilizing a 40amp SSR could I get by with a 25 amp SSR for a 5500 watt element? Is there a such thing as putting two 25amp SSR in series to equal a 50amp SSR? Im asking because I can get the 25amp SSR for free.

Thanks