canyonbrewer

Well-Known Member

calling all DIY-ers!

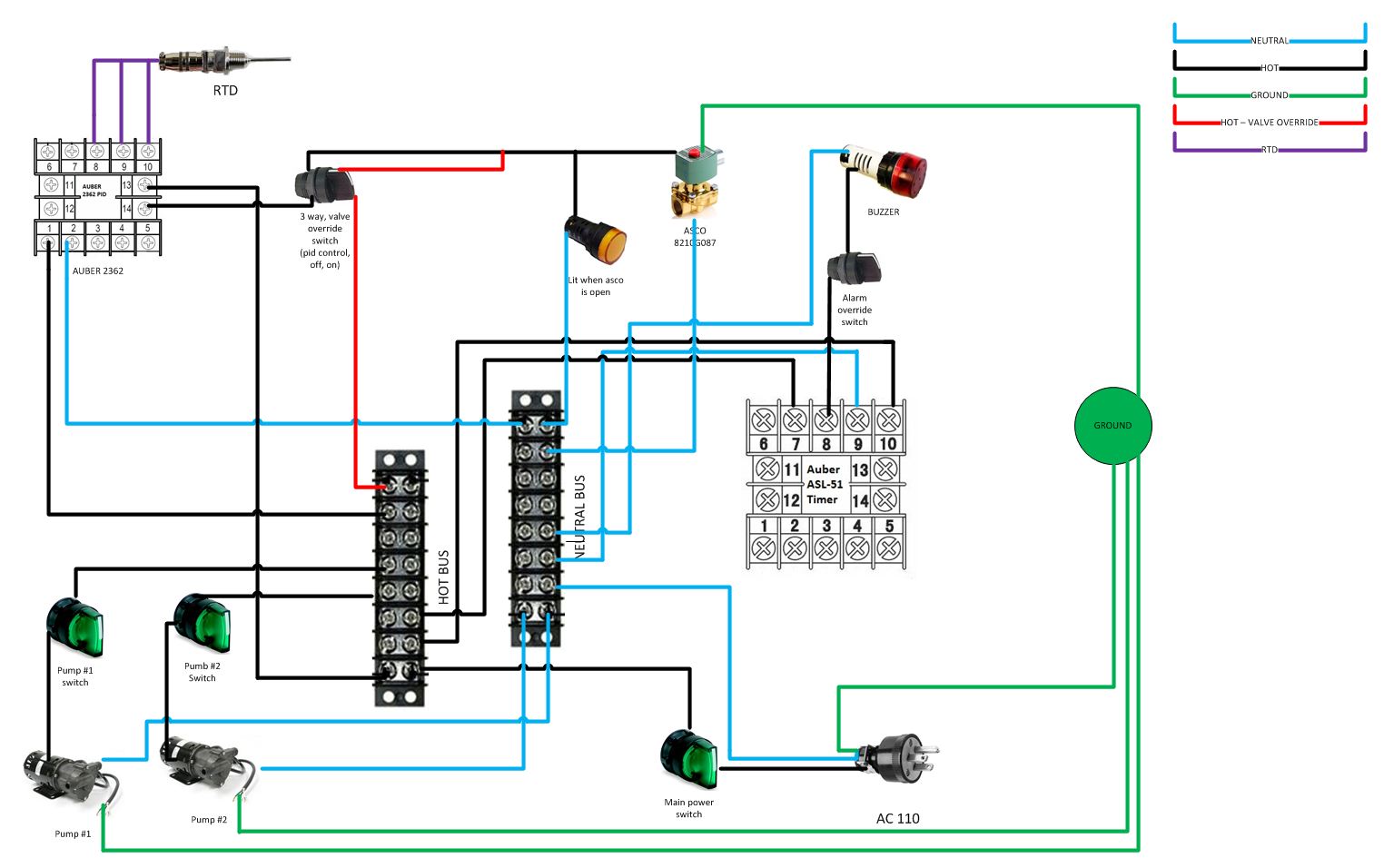

I am a complete wiring newbie...and I am trying to plan the wiring for my build. I am hoping some of you experienced folk are bored tonite, drinking a homebrew, and looking for a diagram to review.

What you see here is the 1st draft my puny brain has come up with...without testing anything.

One particular area where I am confused is the valve override switch and light. Basically, I have a 3 way switch (on/off/on) that I would like to configure as PidControlled/OFF/ManualOn. It is basically 2 switches in 1 (4 contacts). My goal is to be able to override the PID and open the ASCO valve manually. I would also like the yellow light to come on whenever the asco vavle is open, regardless of manual or automatic mode.

Also, I plan on using GFI, but it isn't pictured.

Thanks for all of your help...all feedback is welcomed.

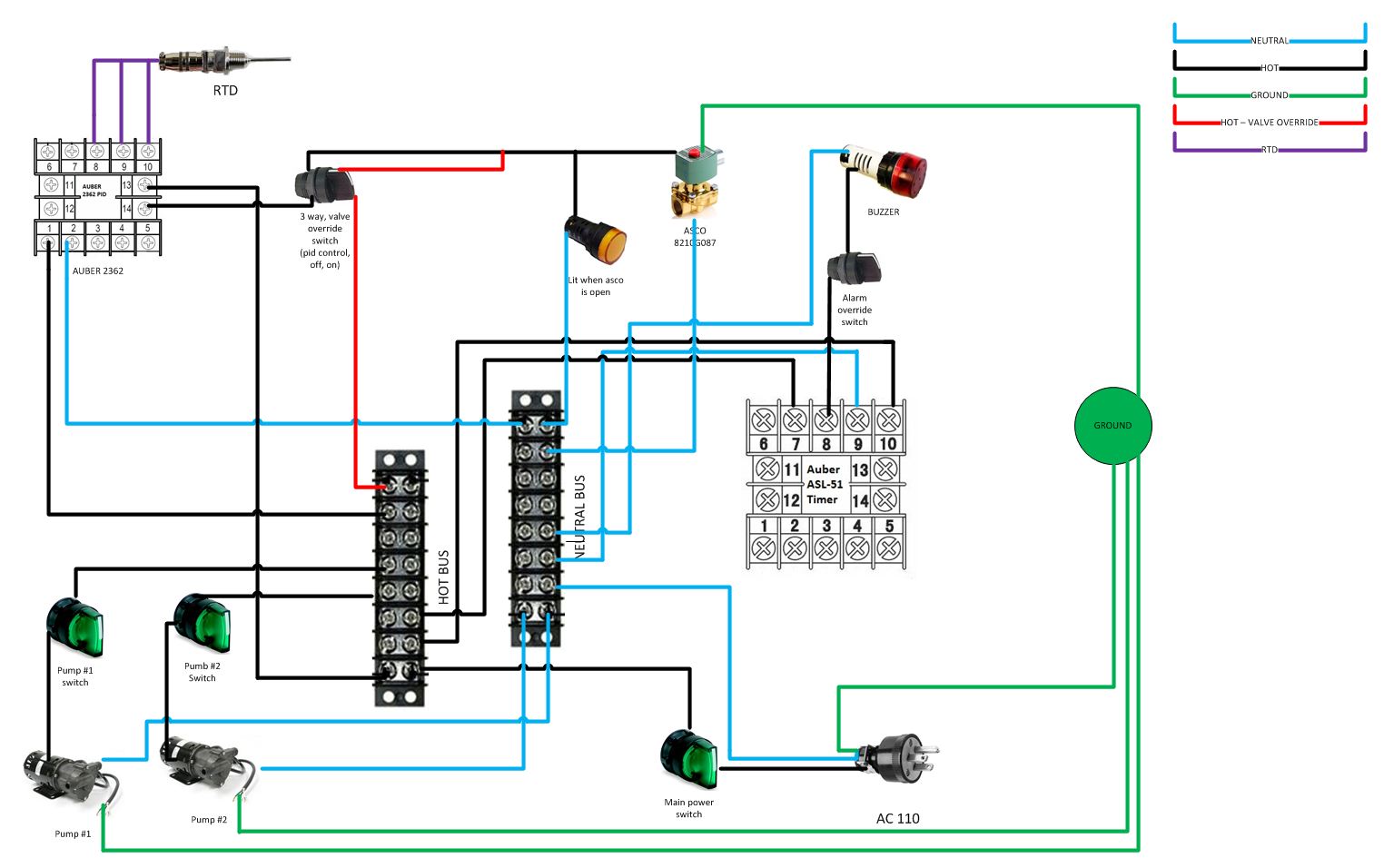

I am a complete wiring newbie...and I am trying to plan the wiring for my build. I am hoping some of you experienced folk are bored tonite, drinking a homebrew, and looking for a diagram to review.

What you see here is the 1st draft my puny brain has come up with...without testing anything.

One particular area where I am confused is the valve override switch and light. Basically, I have a 3 way switch (on/off/on) that I would like to configure as PidControlled/OFF/ManualOn. It is basically 2 switches in 1 (4 contacts). My goal is to be able to override the PID and open the ASCO valve manually. I would also like the yellow light to come on whenever the asco vavle is open, regardless of manual or automatic mode.

Also, I plan on using GFI, but it isn't pictured.

Thanks for all of your help...all feedback is welcomed.