nastee_brew

Active Member

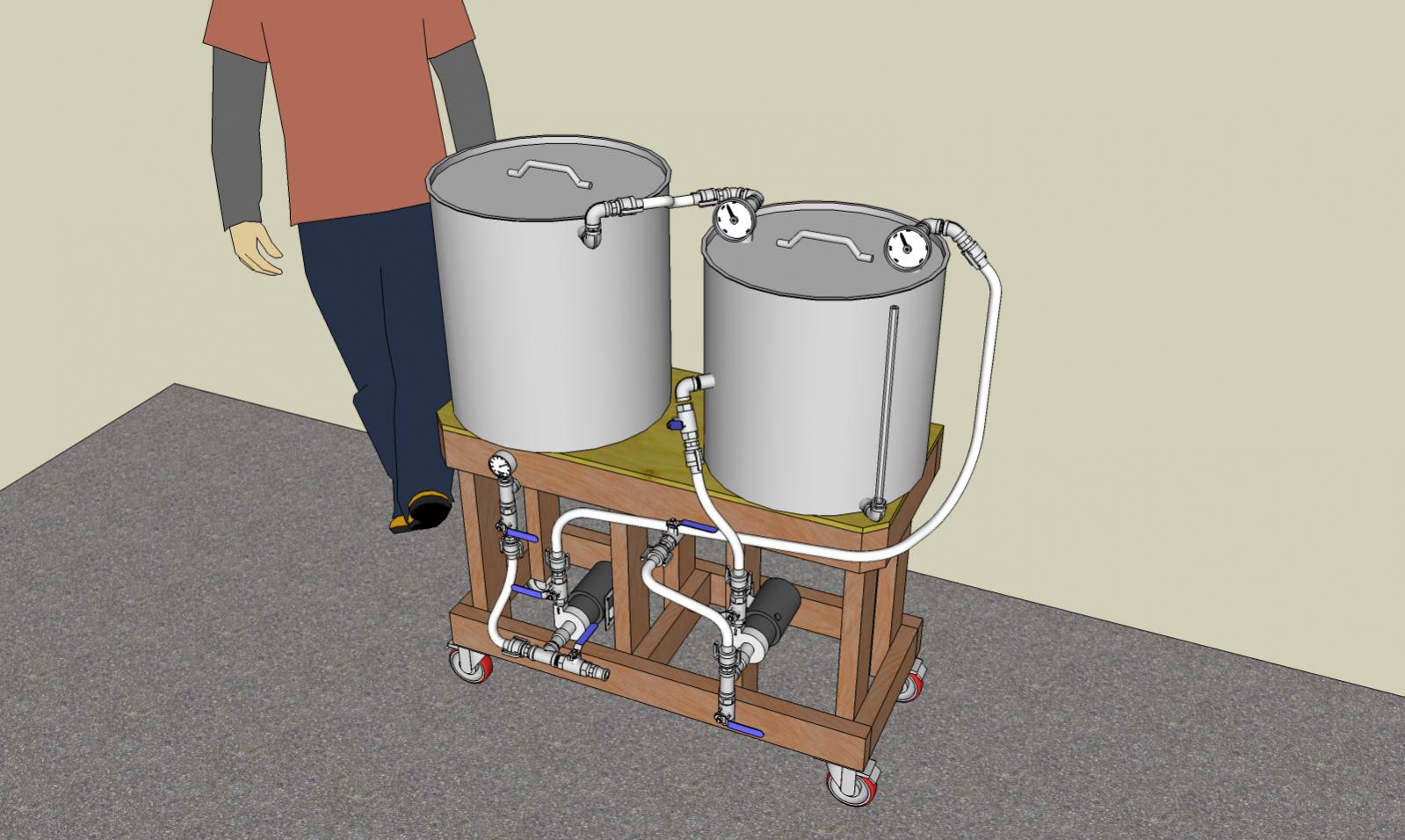

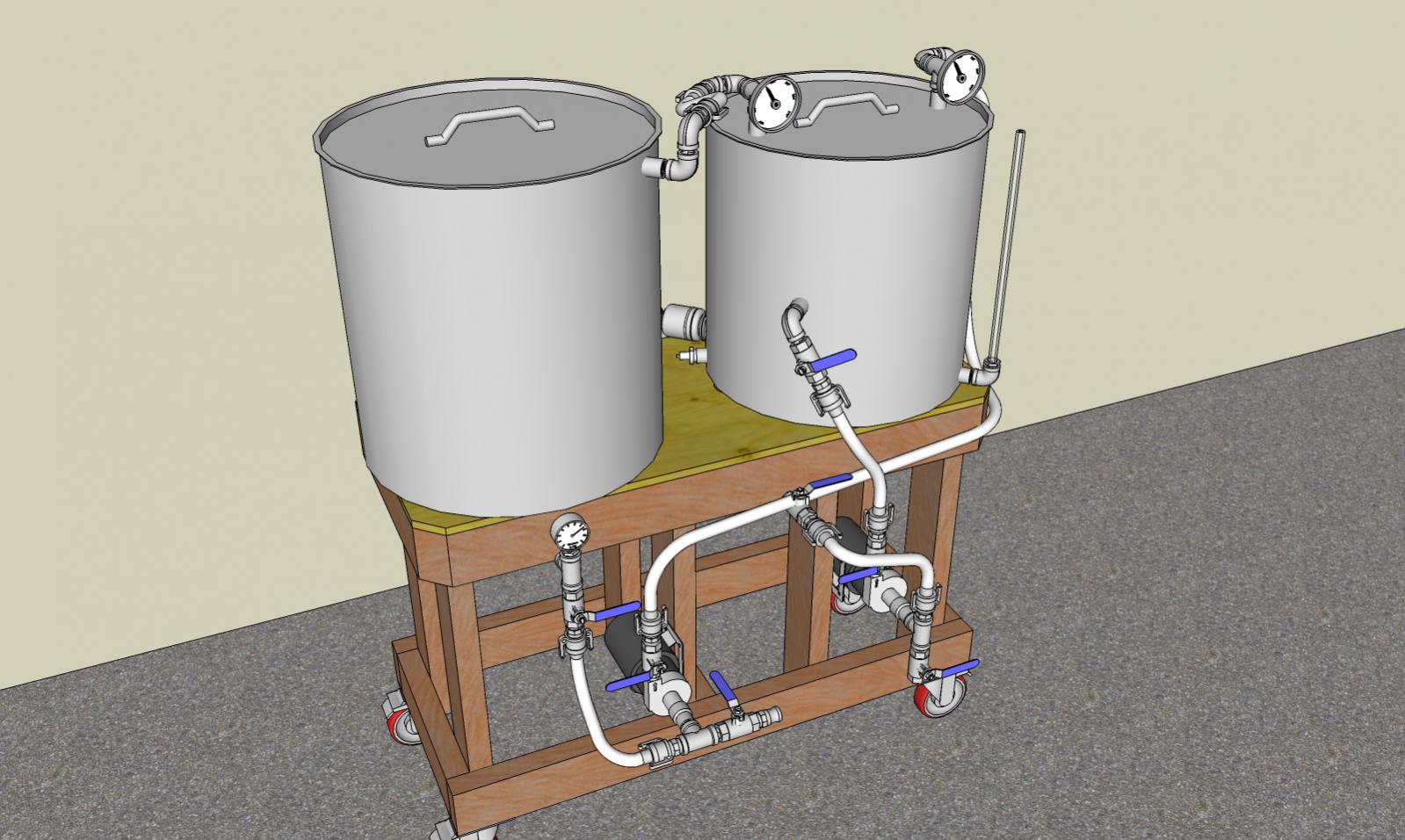

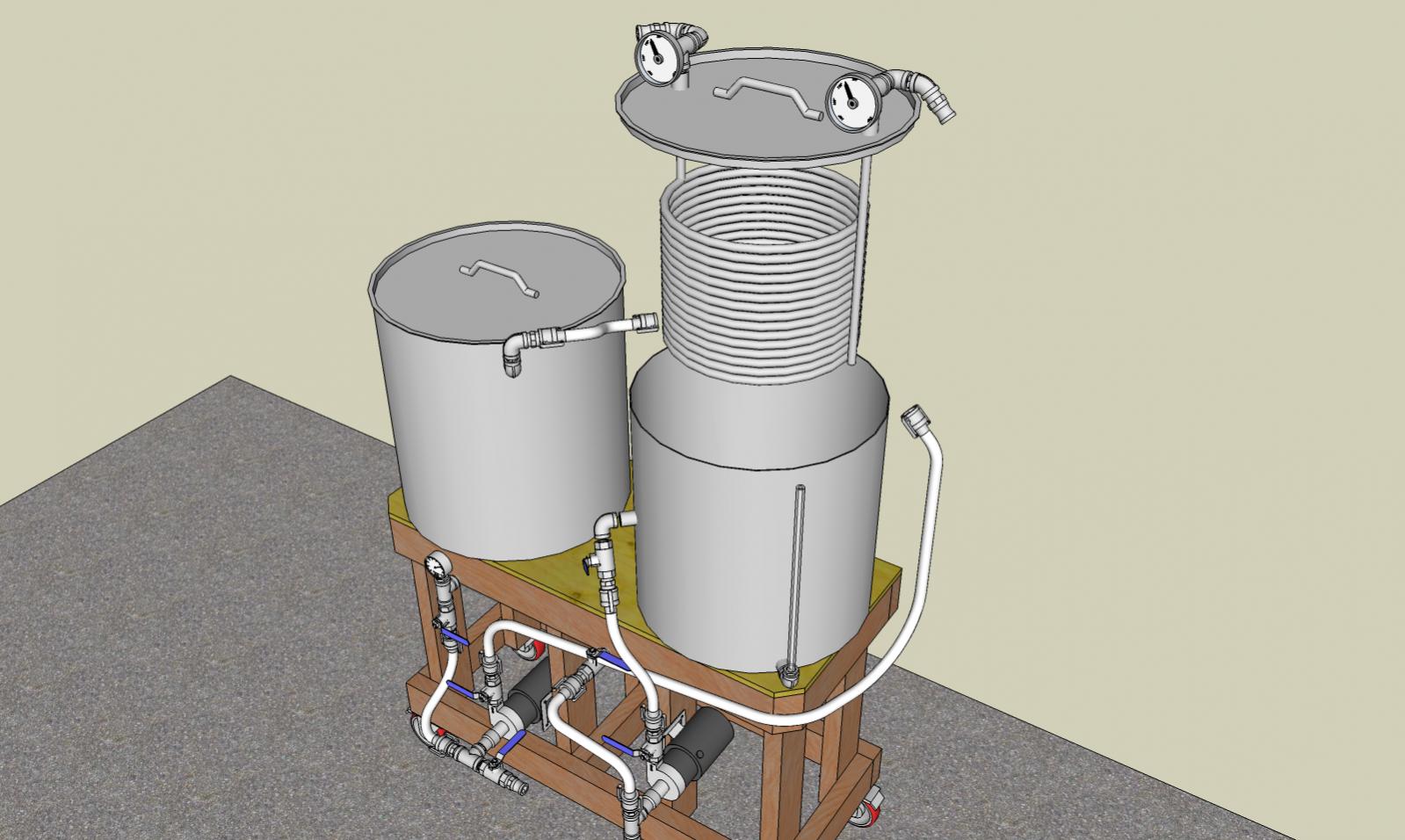

I have just finished a new brewstand. I'm building a keezer, and converting my current kegerator into a fermentation chamber. I'm hoping the fermentation chamber will help my brewing massively. But, that gets me to thinking of my next project.... Has anyone made a drop in HERMs coil? I kind of thought it could sit in my boil kettle full of water at the right temp, and pump wort through it to the MLT. Allowing me to maintain temps on my mash, and even step mash. Just wondering if anyone can lead me to some educational material on similar builds. I just wonder how to make one, what materials are necessary, etc... Thanks for the help.