From what I can tell, those hole-cutters they reference are also crazy-expensive. Is that something that an automotive/electric shop would have and I can just ask nicely to use them for a day?

I went cheap for this. I bought a 3/4" bimetal hole saw from Lowes for like $9. (I see they now have a 7/8" one...wish I'd seen that 2 years ago!). I punch out a 3/4" hole with the saw, then use my dremel to finish it off. For 7/8" holes, (1/2" fittings, 22mm switches/indicators), I usually just use a grinder bit. If I'm lazy, and/or if making bigger holes, (like the 1.2" hole for my BK element), I found that

this drywall cutting bit can actually chew through stainless REALLY fast, so I rough it out with the drywall bit, then finish with a grinder bit so it's smooth.

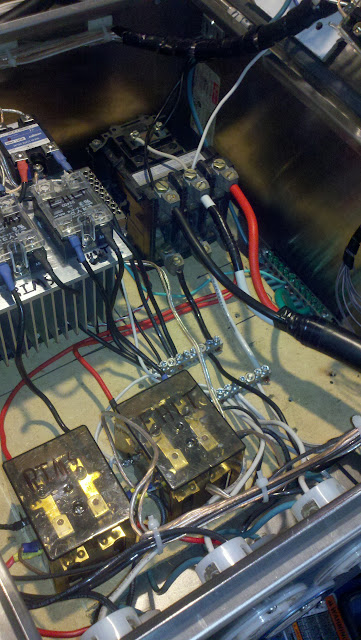

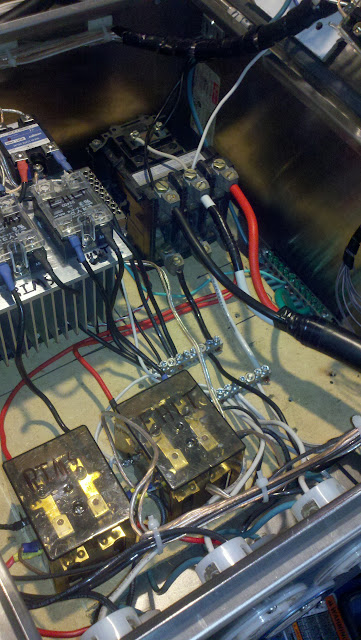

The hole saw has cut 7 holes in keggles, 2 more holes in my stainless 5 gal pot, 3 holes in my aluminum 7.5 gal pot, and about 9 holes so far in my steel control panel, (which is, I think, 12 or 16 ga steel). It's showed no sign of dulling, and I treat it mean. No oil, no lubrication, and full speed on my drill. It punches through a keggle in about 5 seconds flat at full speed, (heats the steel red hot in the process!).