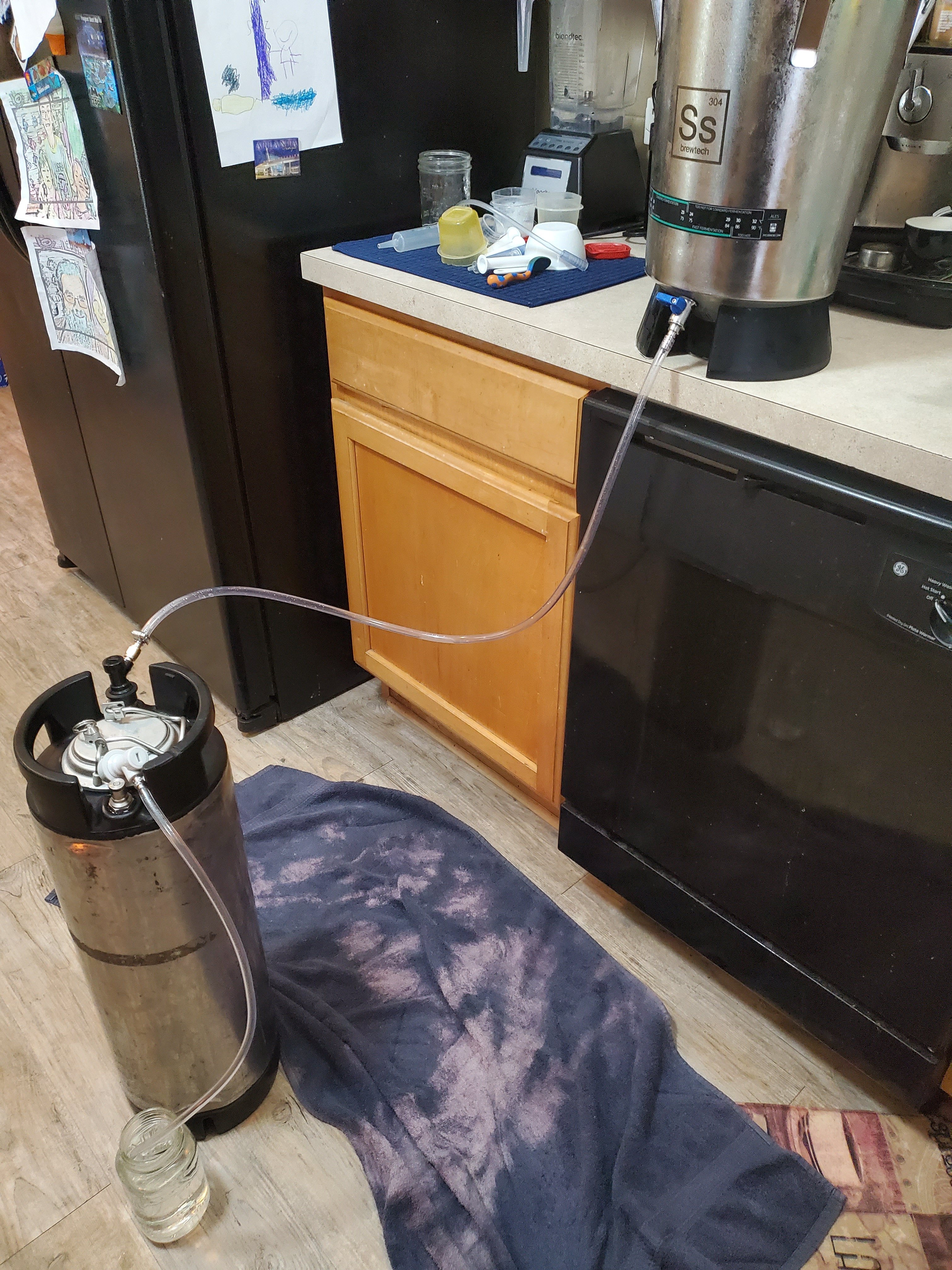

Kegged the blonde on Centennial and Citra dry hops. Hopefully after a cold crash and force carb mid-week I can start tapping it on Friday.

My low-alcohol pale ales seem to be going fast in this heat, so I am putting other beers on the to do list for later and am planning another blonde ale brewday for tomorrow.

My low-alcohol pale ales seem to be going fast in this heat, so I am putting other beers on the to do list for later and am planning another blonde ale brewday for tomorrow.

Last edited:

It's small but more or less functional with the big tools on casters.

It's small but more or less functional with the big tools on casters.