ernestmyname

Well-Known Member

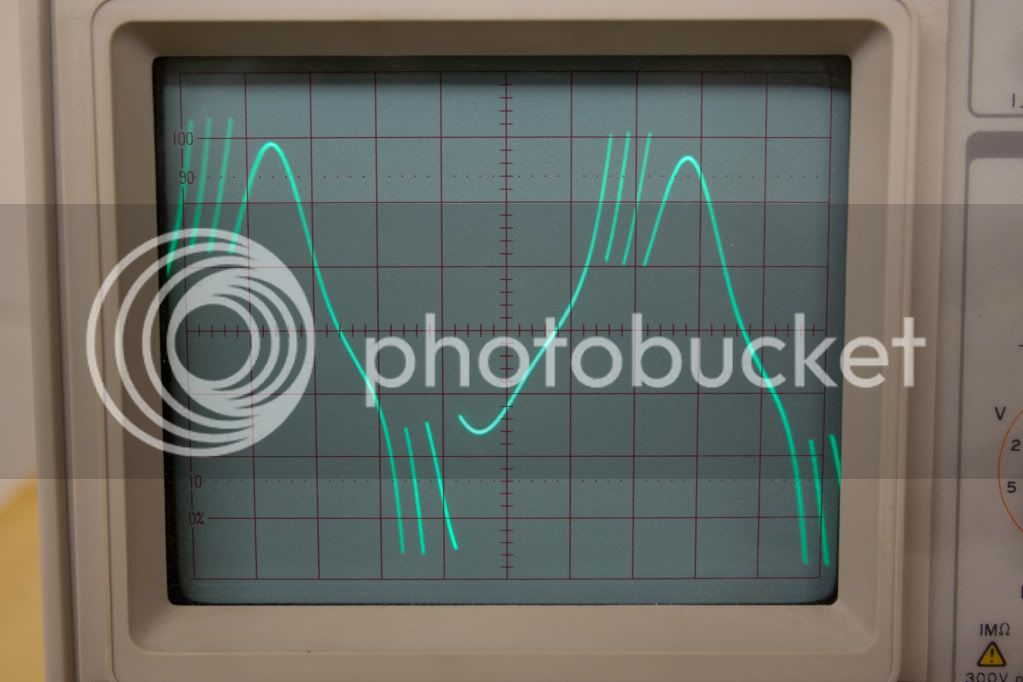

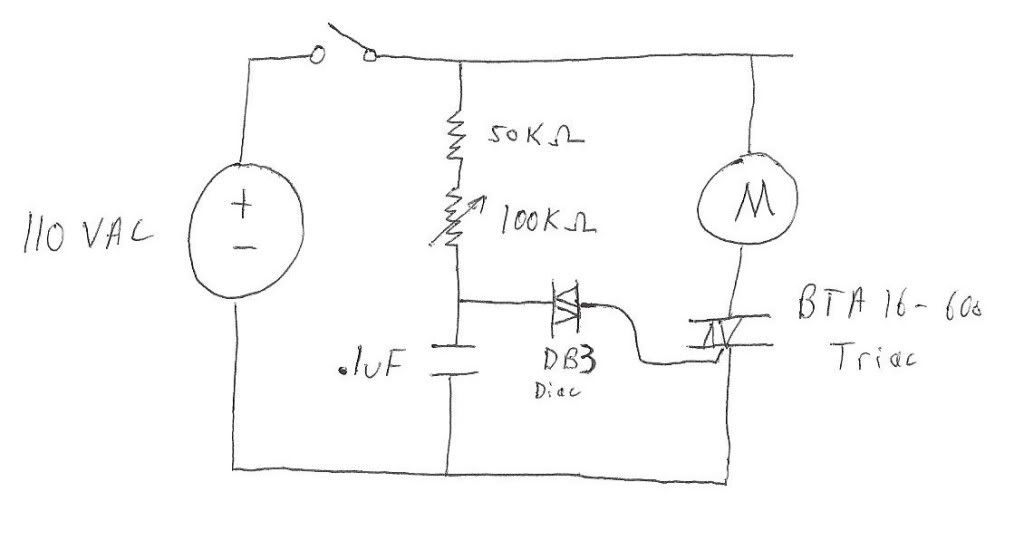

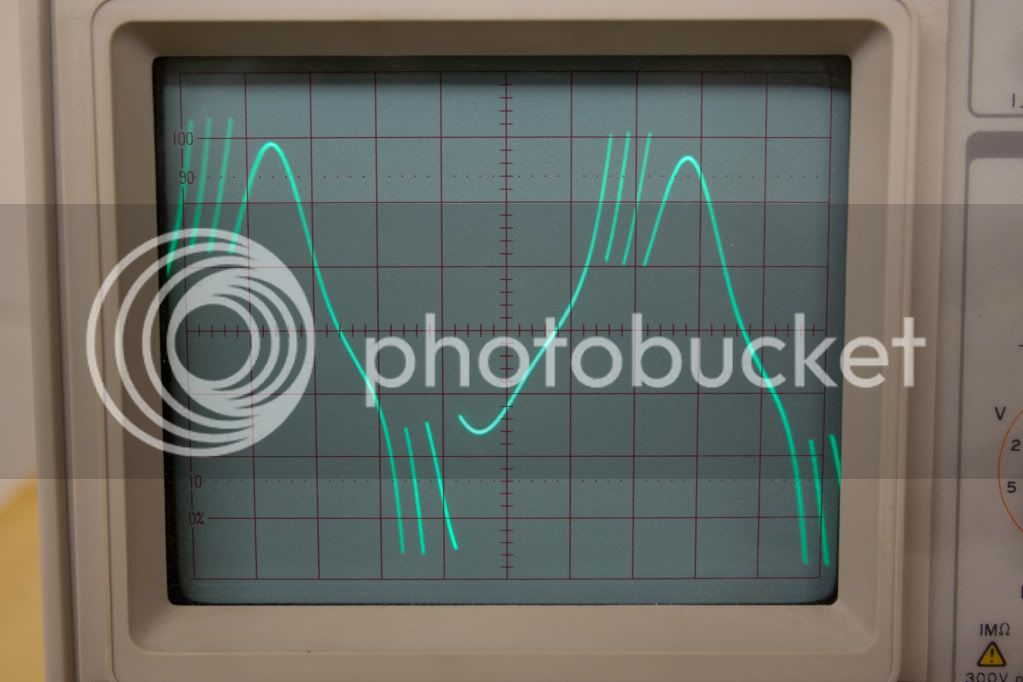

Yet another motorized grain mill. The speed of the mill is varied by a knob mounted on the box with the ON/OFF switch. Max speed is 550RPM. You can't see my hand operating the potentiometer but you can hear the speed changing quite clearly. Having learned some things, I would say i could do the same thing again for around 60usd (counting the cost of the drill). If I had parts lying around I could do it for much less. I can do a cost breakdown and a parts list if anyone is interested. There was quite a bit of modifying that took place. You don't necessarily have to start with a new circuit board although it sure made it easier once I came up with a circuit that worked well. The board in the drill itself is some type of ceramic that is nearly impossible to drill through and cracks very easily. This made modifying the existing circuit/PCB nearly impossible.

With the new parts, my circuit will support a drill up to 16A. Majorly overkill since the drill I'm using is plenty and it is only 7.5A

[ame=http://www.youtube.com/watch?v=RqAs--HDdrs]Motorized Monster Mill - YouTube[/ame]

With the new parts, my circuit will support a drill up to 16A. Majorly overkill since the drill I'm using is plenty and it is only 7.5A

[ame=http://www.youtube.com/watch?v=RqAs--HDdrs]Motorized Monster Mill - YouTube[/ame]