10 gallon and 5 gallon batches, same kettle.

5500W, ULWD element. Assumed 100% energy transfer efficiency since it is inside the kettle, so that is 18,766 BTUs.

1 BTU raises 1 pound of water by 1 degree Fahrenheit in 1 hour. (Gallons * 8.3lbs/gallon * (Boiling - StartTemp))/BTUs = time to boil.

For 10 gallons starting at 70F to boil it is: (10*8.3*(212-70))/18766 = rounded up 38 minutes to boil.

For 5 gallons starting at 70F to boil it is 19 minutes.

These seem like reasonable times to me. Furthermore, if I install a PID/SSR, I can manage the degree of boiling so it is a nice rolling boil rather than a thunderous turn the pot over boil.

Yeah, heating time is not the thing to be concerned about. Sure it's a factor, but there is such a thing as too powerful. 5500W is likely going to make a volcano out of a 5 gallon batch.

But... using a PID to control a boil is overkill, IMO. The whole point of a PID is to use a control algorithm to anticipate temperature changes and adjust things to maintain a precise control. It's essentially a very smart and accurate thermostat. Unfortunately, the temp of a boil is constant regardless of the strength of it, so a PID really can't do what you need.

Those that use PIDs to control boils actually use them in a "manual mode" which doesn't even utilize actual PID control algorithm at all. It just generates a manually defined pulse to control the percentage of time that your heating element is ON vs. OFF. The temp probe can be left dangling in the air when using a PID in manual mode... it's not needed.

Anyway... you can generate a pulse for much cheaper than the price of a PID.

"IF" one is available, an infinite switch will give the same control as a PID/SSR all in one unit. Like an electric stove does.

I just had a conversation on here the other day about infinite switches. They do generate a pulse, and are a nice off the shelf, complete solution for controlling boil strength. But, it sounds like the biggest ones available can only handle 15A, which is sufficient to drive a 3500W element @240V, but not 5500W. You'd need 25A for that size element.

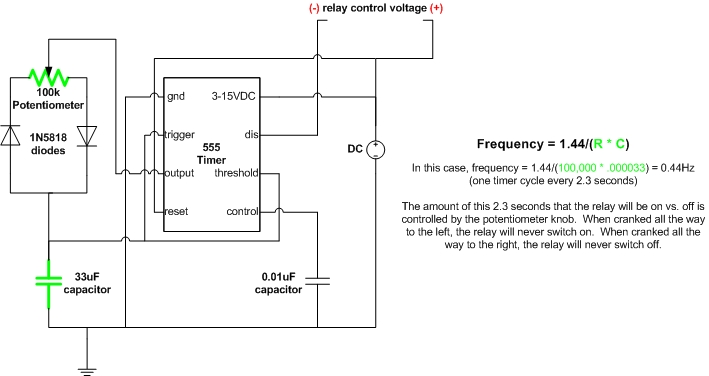

The other alternative is to build a simple pulse width modulator. I've built a couple of these recently and it literally costs less than $5 to make one. It does take some time to assemble with a soldering iron, but it consists of one potentiometer, one small chip, two capacitors, and two diodes. You still need an SSR for the modulator to control, but it's a lot cheaper than paying for a PID that you will be under-utilizing by putting it into manual mode.

If you want convenience and/or the possibility for other system changes in the future (HERMS or RIMS or automated heating of water to set temps) then a PID that supports manual mode (note that not all of them do!) is probably a good choice.

If you want cheap 5500W boil control and aren't afraid to solder some things together, then a DIY pulse width modulator and an SSR might be what you want.