cyberbackpacker

Well-Known Member

EDIT: Okay, I have a question in regards to this brew. It fermented for 29 days between 62-66F. It finished at 1.020-- high but I did mash at 156 and only did a 60 minute mash.

My question after 29 days I went to crash cool it before transferring to keg (this will be my first time kegging). However with the craziness of Christmas I has been sitting at 36F for two weeks now.

I have seen when people Lager they raise it up to 60F+ for a diacetyl rest I believe. Then crash cool before kegging/bottling.

How should I proceed? Should I just go ahead and rack it to the keg? Or should I bring it up to primary ferm temps again for a day or two, crash cool for a day or two, then keg? Something else?!?

Thanks for the help.

END EDIT

ORIGINAL POST

Just got done with Northern Brewers Irish Draught Ale; I brewed it on a restaurant gas stove and it was my first time doing a full 5 gallon AG batch.

Amount Item Type % or IBU

6.50 lb Pale Malt, Maris Otter (3.0 SRM) Grain 76.47 %

0.50 lb Caramel/Crystal Malt - 10L (10.0 SRM) Grain 5.88 %

0.25 lb Chocolate Malt (450.0 SRM) Grain 2.94 %

0.25 lb Oats, Malted (1.0 SRM) Grain 2.94 %

1.00 oz Challenger [7.50 %] (45 min) Hops 27.6 IBU

1.00 lb Honey (1.0 SRM) Sugar 11.76 %

Windsor Yeast pitched at 64 F

Mashed in @ 1.25qt: 1 lb at 156 F degrees and double batch sparged with 2.75 gallons at 168 F.

Boiled off more than I expected and ended up at 4.75 gallons.

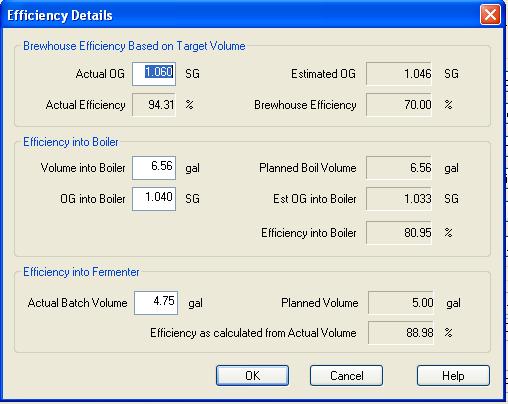

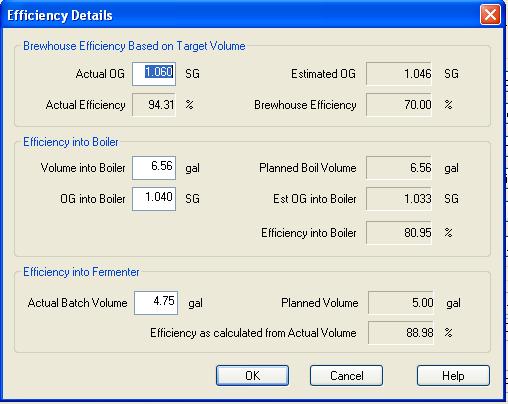

These are my beersmith numbers for this batch:

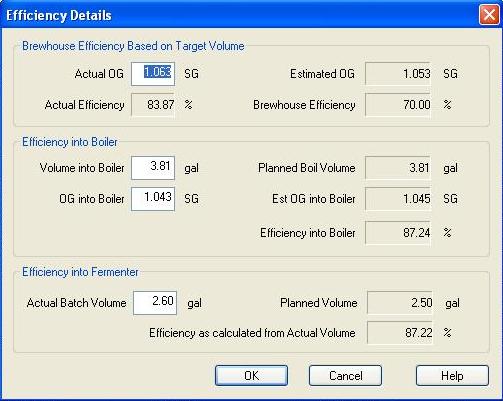

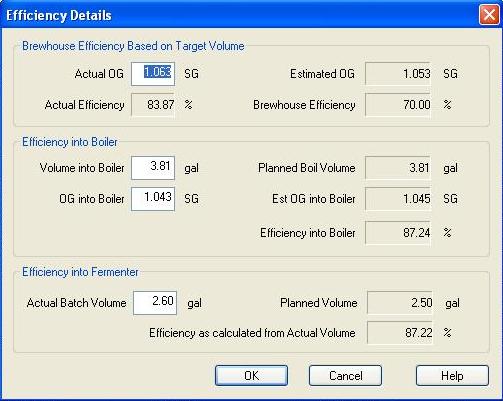

Here are the ones from my Winterfest from November 1:

Am I understanding Beersmith correctly? My brewhouse efficiency is what I should calculate my recipes towards? However, the efficiency into fermenter tells me the actual efficiency for that particular batch because of the actual collected volume and specific gravity?

If that is the case, I think I am fairly consistent so far; 87.22% into the fermenter on my first batch on 11/1/08 and 88.98% into the fermenter yesterday.

Considering one was a 2.5g batch and the other 5g, and one was done on a ceramic residential cooktop vs. professional gas, I am pleased. However, seeing that I have hit over 80% on both batches, I should probably change my expected efficiency from 70% up to ~80%.

My question after 29 days I went to crash cool it before transferring to keg (this will be my first time kegging). However with the craziness of Christmas I has been sitting at 36F for two weeks now.

I have seen when people Lager they raise it up to 60F+ for a diacetyl rest I believe. Then crash cool before kegging/bottling.

How should I proceed? Should I just go ahead and rack it to the keg? Or should I bring it up to primary ferm temps again for a day or two, crash cool for a day or two, then keg? Something else?!?

Thanks for the help.

END EDIT

ORIGINAL POST

Just got done with Northern Brewers Irish Draught Ale; I brewed it on a restaurant gas stove and it was my first time doing a full 5 gallon AG batch.

Amount Item Type % or IBU

6.50 lb Pale Malt, Maris Otter (3.0 SRM) Grain 76.47 %

0.50 lb Caramel/Crystal Malt - 10L (10.0 SRM) Grain 5.88 %

0.25 lb Chocolate Malt (450.0 SRM) Grain 2.94 %

0.25 lb Oats, Malted (1.0 SRM) Grain 2.94 %

1.00 oz Challenger [7.50 %] (45 min) Hops 27.6 IBU

1.00 lb Honey (1.0 SRM) Sugar 11.76 %

Windsor Yeast pitched at 64 F

Mashed in @ 1.25qt: 1 lb at 156 F degrees and double batch sparged with 2.75 gallons at 168 F.

Boiled off more than I expected and ended up at 4.75 gallons.

These are my beersmith numbers for this batch:

Here are the ones from my Winterfest from November 1:

Am I understanding Beersmith correctly? My brewhouse efficiency is what I should calculate my recipes towards? However, the efficiency into fermenter tells me the actual efficiency for that particular batch because of the actual collected volume and specific gravity?

If that is the case, I think I am fairly consistent so far; 87.22% into the fermenter on my first batch on 11/1/08 and 88.98% into the fermenter yesterday.

Considering one was a 2.5g batch and the other 5g, and one was done on a ceramic residential cooktop vs. professional gas, I am pleased. However, seeing that I have hit over 80% on both batches, I should probably change my expected efficiency from 70% up to ~80%.