I had a chat with Reelale about a mash tun make from a Sanke that was NOT going to be direct heated. It would be used for basic infusion mashing and the temp would be held with a RIMS tube (though HERMS is equally valid). For sure, a little closed foam or reflectix insulation wouldn't hurt either.

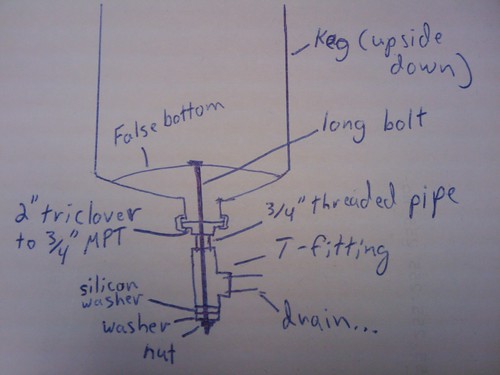

I got to suggesting using a bottom drain on it if it hadn't already been drilled. Keep in mind, this should work very well for ANY sanke vessel EXCEPT for a direct fired boil kettle or mash tun. Everything else is fair game; passive MLT, HLTs of any kind, and electrically heated boil kettles too. The next two images show how I'd do it if a false bottom is desired for either the MLT or a coarse whole hop filter in a boil kettle.

If you do NOT need the false bottom, the nipple, cap and locknut would just be replaced with a 1/2" x 3/8 hex threaded reducing bushing. Done.

The alternative for this type of use is to get a 2" triclover to 1/2 FPT and clamp it to the top neck, then invert the keg and cut a hole in the bottom. Of course, that's a bit more pricey.

I got to suggesting using a bottom drain on it if it hadn't already been drilled. Keep in mind, this should work very well for ANY sanke vessel EXCEPT for a direct fired boil kettle or mash tun. Everything else is fair game; passive MLT, HLTs of any kind, and electrically heated boil kettles too. The next two images show how I'd do it if a false bottom is desired for either the MLT or a coarse whole hop filter in a boil kettle.

If you do NOT need the false bottom, the nipple, cap and locknut would just be replaced with a 1/2" x 3/8 hex threaded reducing bushing. Done.

The alternative for this type of use is to get a 2" triclover to 1/2 FPT and clamp it to the top neck, then invert the keg and cut a hole in the bottom. Of course, that's a bit more pricey.

In a keg with a domed bottom, you'd have almost no liquid left!

In a keg with a domed bottom, you'd have almost no liquid left!