http://cgi.ebay.com/Outdoor-Wood-Fu...ltDomain_0&hash=item35a4c9e506#ht_2961wt_1137

This thing is 12" x 4.25" x 3" in size with 50 plates.

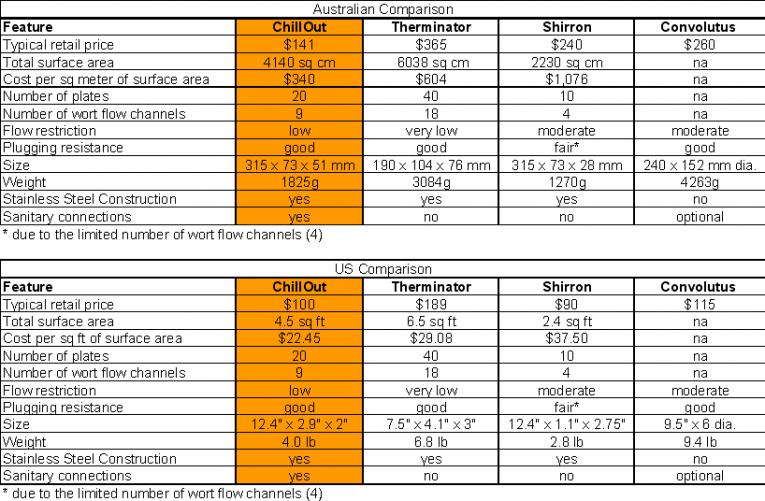

If my math is correct this thing is about 17.7 ft^2 of cooling area making is almost 3X the size of the Therminator and 7.35x the Shirron.

Am I missing something here?

It's $196 shipped and is 316 SS which is great.

It has 1" MPT fittings so I would need some reducers.

But otherwise this seems like the ultimate. I would think I could chill down to like 1-2F above water temps with this thing at a decent rate. If my water temps are 55F, could I get down to say 62F at full throttle of wort flow?

No I do not work for this company.

I am just trying to decide on a plate chiller and this thing seems amazing.

This thing is 12" x 4.25" x 3" in size with 50 plates.

If my math is correct this thing is about 17.7 ft^2 of cooling area making is almost 3X the size of the Therminator and 7.35x the Shirron.

Am I missing something here?

It's $196 shipped and is 316 SS which is great.

It has 1" MPT fittings so I would need some reducers.

But otherwise this seems like the ultimate. I would think I could chill down to like 1-2F above water temps with this thing at a decent rate. If my water temps are 55F, could I get down to say 62F at full throttle of wort flow?

No I do not work for this company.

I am just trying to decide on a plate chiller and this thing seems amazing.