You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

What I did for beer today

- Thread starter iaefebs

- Start date

Help Support Homebrew Talk - Beer, Wine, Mead, & Cider Brewing Discussion Forum:

This site may earn a commission from merchant affiliate

links, including eBay, Amazon, and others.

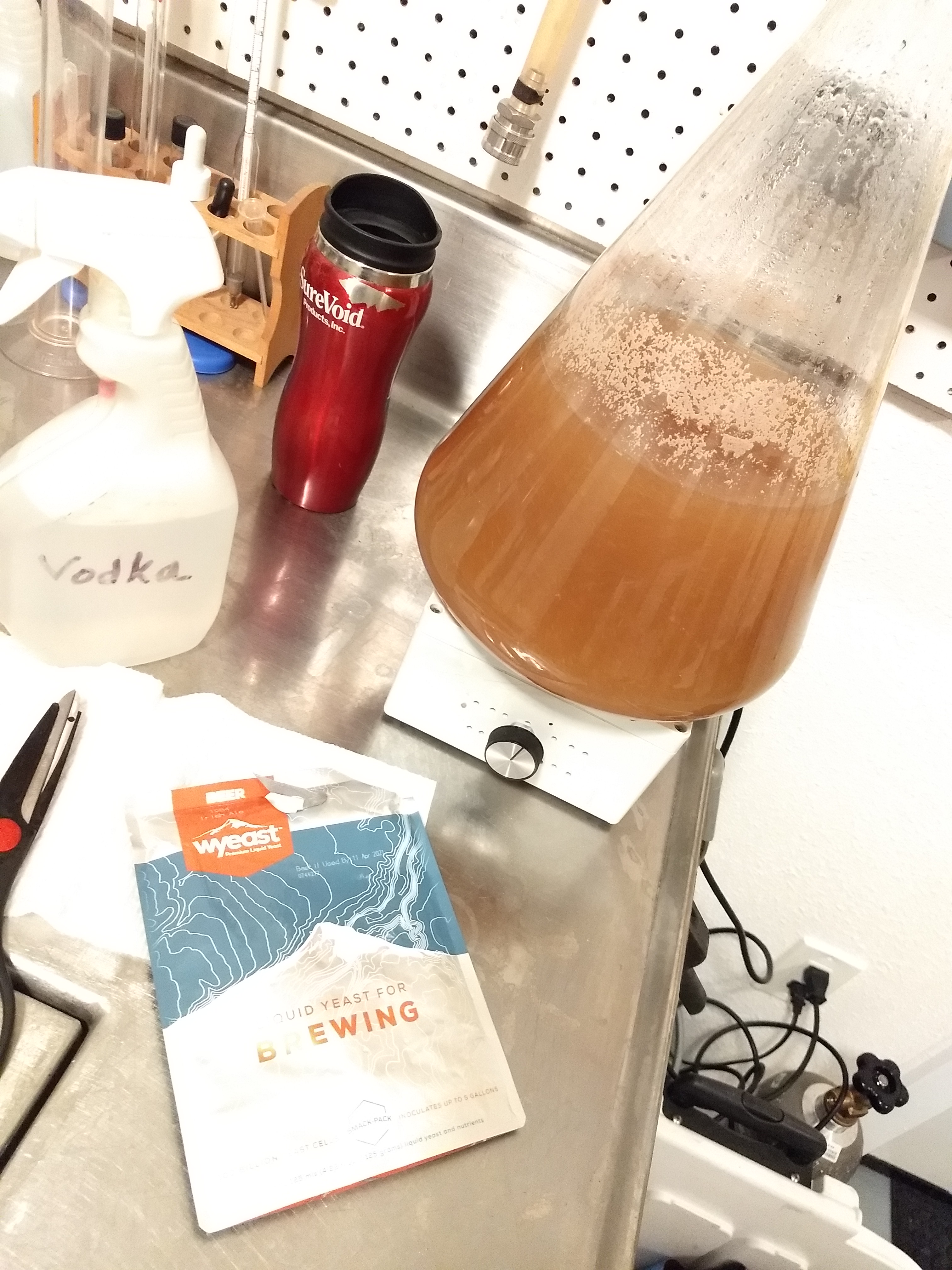

Got starter going for my Scottish Export. First of two.

Nokie

Well-Known Member

kegging beer and washing yeast

Today I am adding 26oz of dark wildflower honey, 2.7oz of candied ginger and 2oz of Cluster dry hops to the 2020-12 Beers of Christmas-West Coast, Honey-Ginger IPA.

Sipping on some homebrew while I ponder on this year's Holiday Ale recipe. Planning on bottling the whole batch this year so I need to get going on it in the next two weeks. I've done the last three years Holiday Ale with an american strong base beer while playing with the spice additions. This year I might add a touch of chocolate malt with some flaked barley to up the mouthfeel, and up the spice additions to a full 22oz bottle filled with capn morgan rum and a TON of spice, this year to include our usual cinnamon, nutmeg, allspice, pumpkin pie spice, and what I have left of dried orange peel. This year going for something close to Old Fezziwig but with a knock-your-ugly-holiday-socks-off spice kick, just for the heck of it. Also too much fun to sit here and think about it. Also want to amaze my perfect sister who never fails to find a holiday ale at the local store to challenge my brewing skills.

FOUND THE KEG LUBE!! Under the ferment fridge. Still good. Yay!!!Nope. That damn tube (which I've been using since I started kegging three years ago) has flown the proverbial coop. Had to use vaseline on the last keg, yes I know it's pretty much the same thing, but that crunched up tube has some memories in it.

Brewed up a holiday ale using 3.3 lbs of Munich LME, 6.6 lbs of Pale Pilsner LME, an ounce of Cluster (bittering), an ounce of Hallertau (aroma) and a pint of a coriander/orange peel/cinnamon infusion. Left me 5.5 gals of a fairly sweet and spicy wort (before adding Saison I yeast) that tastes great just as it is now... I can't wait to see what the yeast does to it!

Went to LHBS for CO2, grain for a stout and a DIPA, some fresh yeasties, and bottle caps for the Christmas beers. 2 1/2 years in to full-time hobby brewing, and I am definitely learning how to schedule the year's brew days for optimum production.

I put my dying keezer to rest today. My second keezer, it didn't quite make it to its 9th birthday.

It was a great machine, reliable as hell (until it wasn't), always good pours...

Hoping the next build will be a little bit cleaner in the back...

...but it's definitely going to be much less cramped inside.

Totally stripped it clean of parts for the new build.

I'll eventually stuff the carcass in the back of my Durango and haul it to the same store that sold me its replacement for disposal.

Meanwhile...K3 gets ever closer to "done"...

Cheers!

It was a great machine, reliable as hell (until it wasn't), always good pours...

Hoping the next build will be a little bit cleaner in the back...

...but it's definitely going to be much less cramped inside.

Totally stripped it clean of parts for the new build.

I'll eventually stuff the carcass in the back of my Durango and haul it to the same store that sold me its replacement for disposal.

Meanwhile...K3 gets ever closer to "done"...

Cheers!

- Joined

- Feb 19, 2017

- Messages

- 959

- Reaction score

- 1,217

Kegged 5 gallons of an ordinary bitter testing out Archer hops with w yorkie yeast.

Have a Irish Oat Stout currently cooling to pitch temperature. Trouble is, I don't have a clean fermenter, voila test out my stout pitched on the w yorkie yeast cake.

Kegged 2.5 gallons of a Machine House Mild clone first attempt with DME. (Machine HOuse brewery in Seattle has the most incredible, complex, multi layered mild. I've done ~10 all grain batches that have gotten kinda close but not quite a clone. Recently picked up 55# of pilsner DME. So this is the first test with the DME to see if I can get close. I need to go back and talk to the brewer again. He uses US 2 row, bairds Crystal 50-60, Bairds Crystal 135-165, Bairds chocolate, fuller's yeast, and a mix of EKG/nugget/progress. This stuff is the BOMB: Dark Mild .

Have a Irish Oat Stout currently cooling to pitch temperature. Trouble is, I don't have a clean fermenter, voila test out my stout pitched on the w yorkie yeast cake.

Kegged 2.5 gallons of a Machine House Mild clone first attempt with DME. (Machine HOuse brewery in Seattle has the most incredible, complex, multi layered mild. I've done ~10 all grain batches that have gotten kinda close but not quite a clone. Recently picked up 55# of pilsner DME. So this is the first test with the DME to see if I can get close. I need to go back and talk to the brewer again. He uses US 2 row, bairds Crystal 50-60, Bairds Crystal 135-165, Bairds chocolate, fuller's yeast, and a mix of EKG/nugget/progress. This stuff is the BOMB: Dark Mild .

Finally kegged up the Chocolate stout I brewed two weeks ago; came down to 1.020 from 1.074 and didn't budge for a couple days, so it's done. First time using cocoa powder in a stout, and it's very nice. I've had bad luck with lactose in stouts so I left that out, but added some flaked barley to this one with the oats to help along the mouthfeel. Pics will be coming tomorrow once it's carbed up a bit. And here's a pic of one of my two black cats (this is my girl Sophia) supervising the boil today.

![20201010_082649[1].jpg 20201010_082649[1].jpg](https://cdn.homebrewtalk.com/data/attach/642/642524-20201010-082649-1-.jpg)

![20201010_082649[1].jpg 20201010_082649[1].jpg](https://cdn.homebrewtalk.com/data/attach/642/642524-20201010-082649-1-.jpg)

Nick&Worty

Well-Known Member

- Joined

- Sep 2, 2020

- Messages

- 282

- Reaction score

- 440

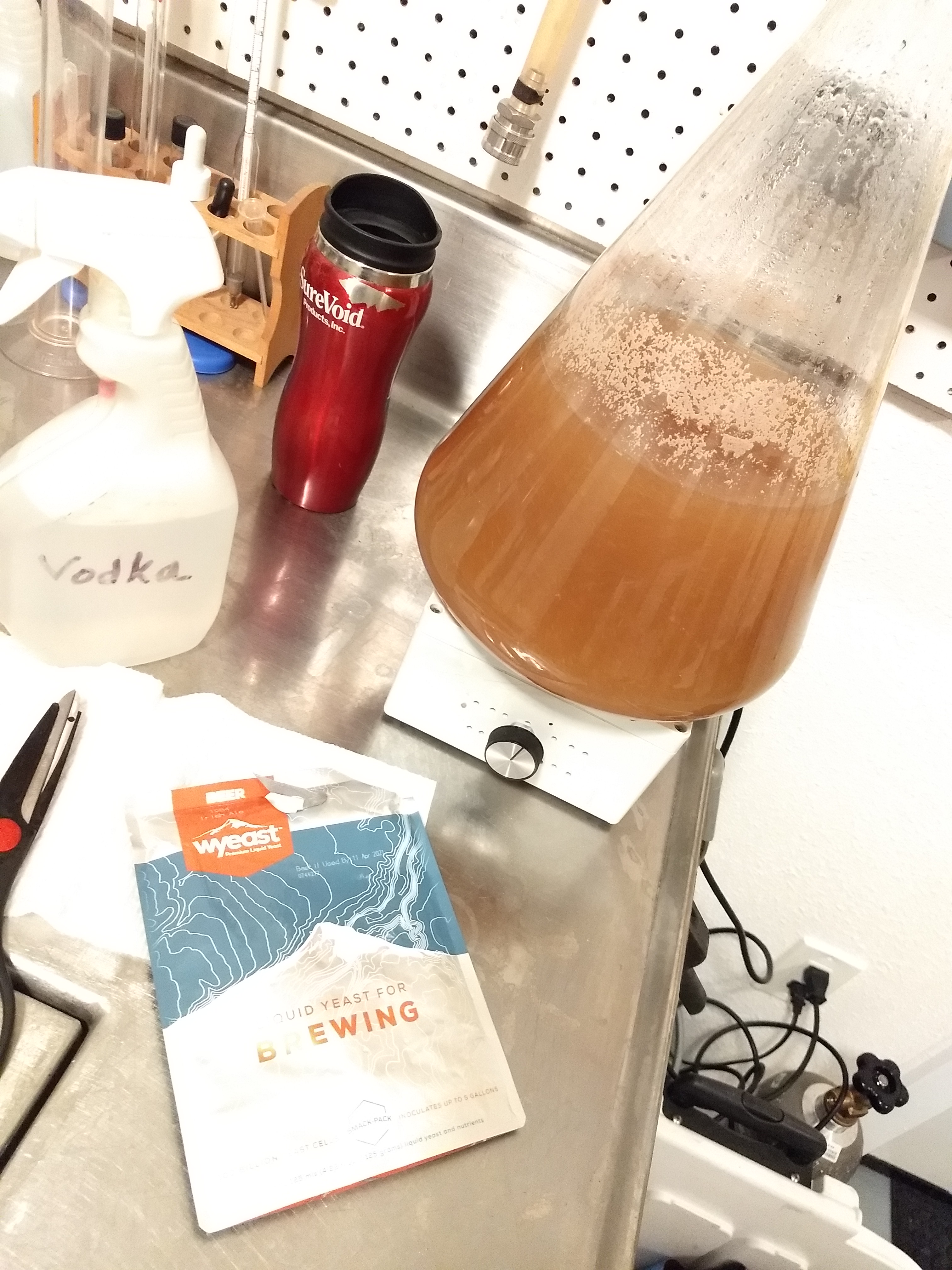

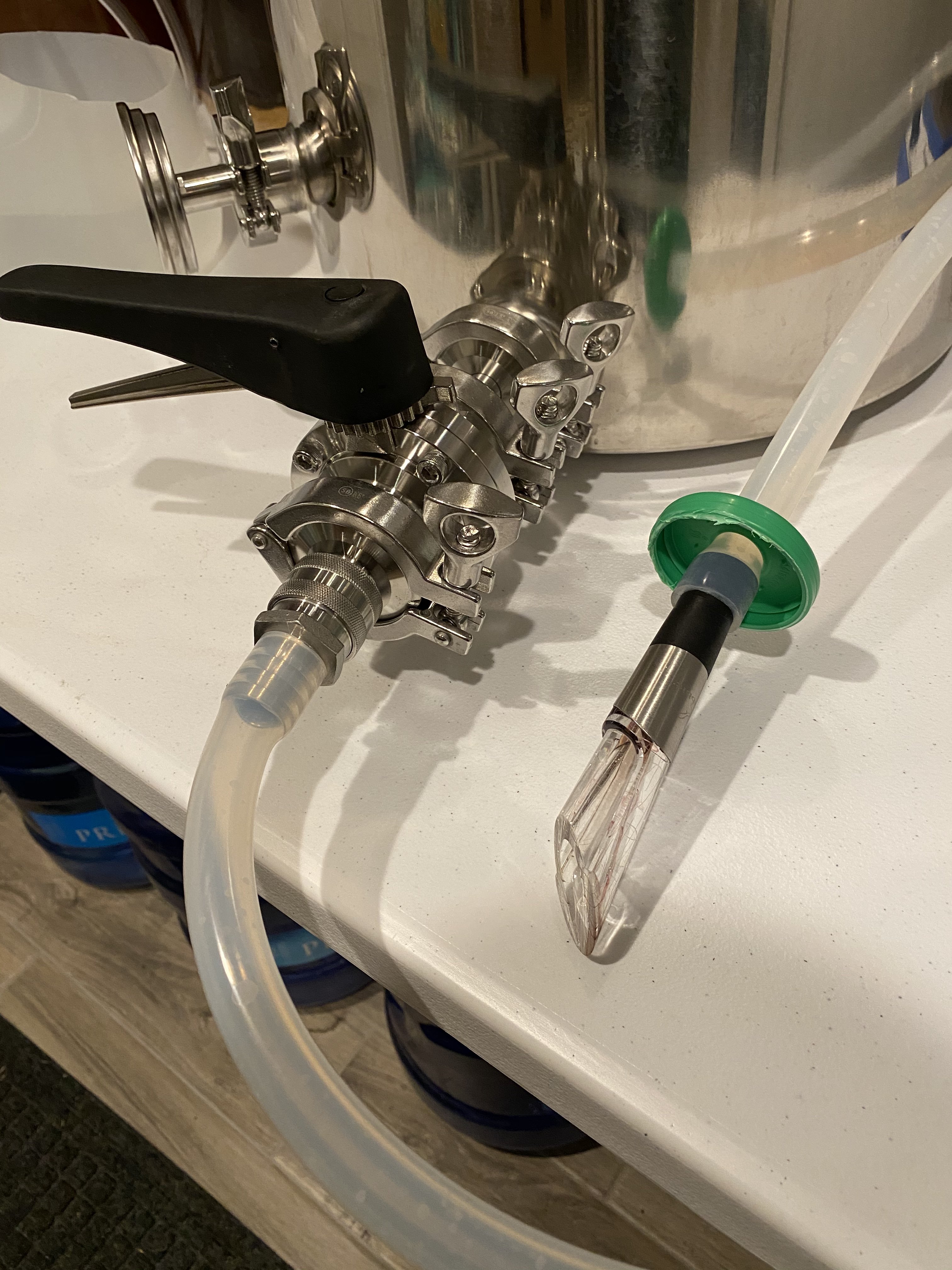

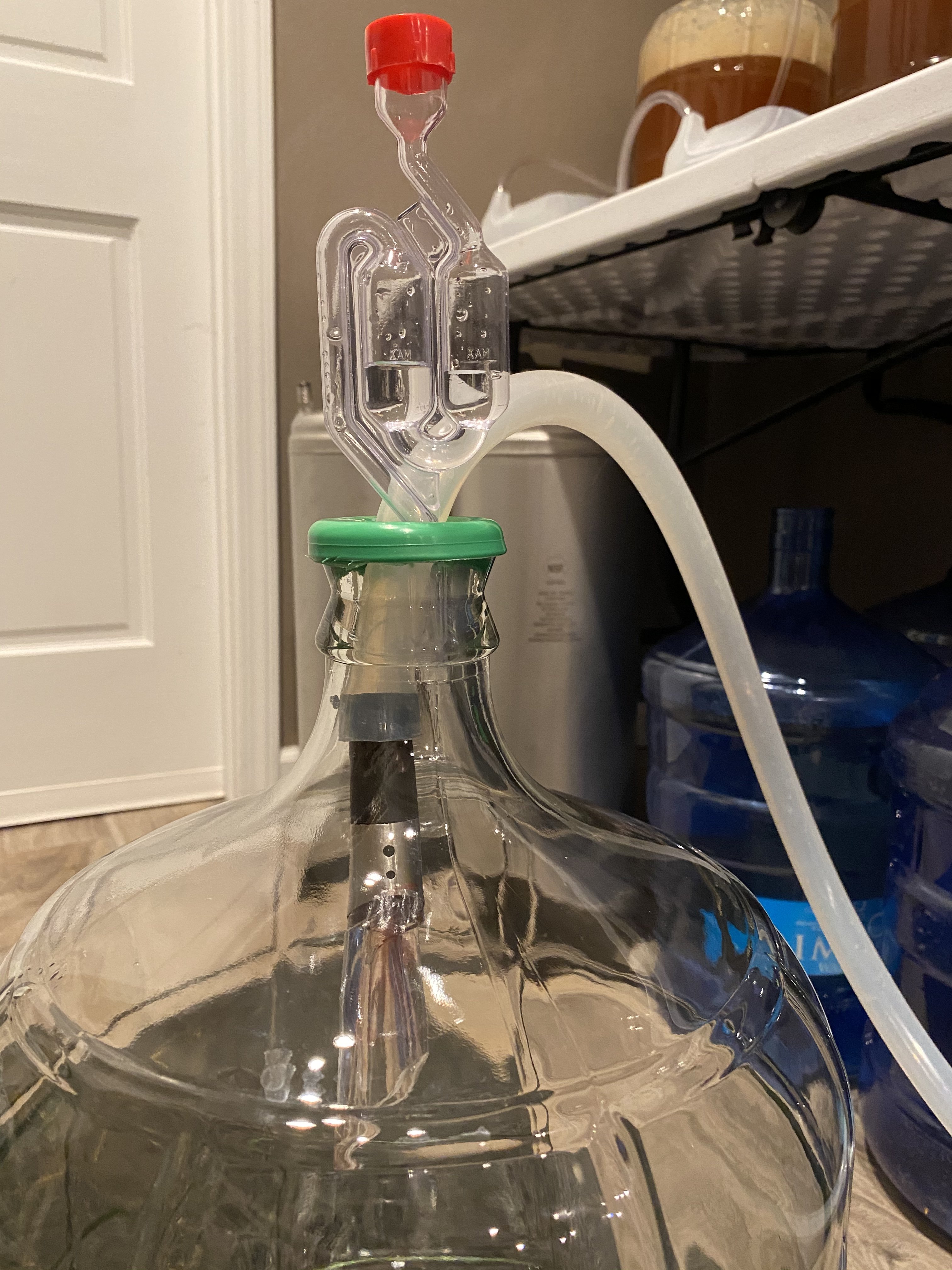

Alright friends, it’s MacGyver time again! I’ve got an idea, and I want to know what you think. Like I mentioned in a previous post, I ran out of O2 last time I brewed, and had to resort to shaking the crap out of the carboy. That fermentation seems to have gone well, and I’ve read conflicting things on whether my O2 wand is even that useful for standard gravity ales and such.

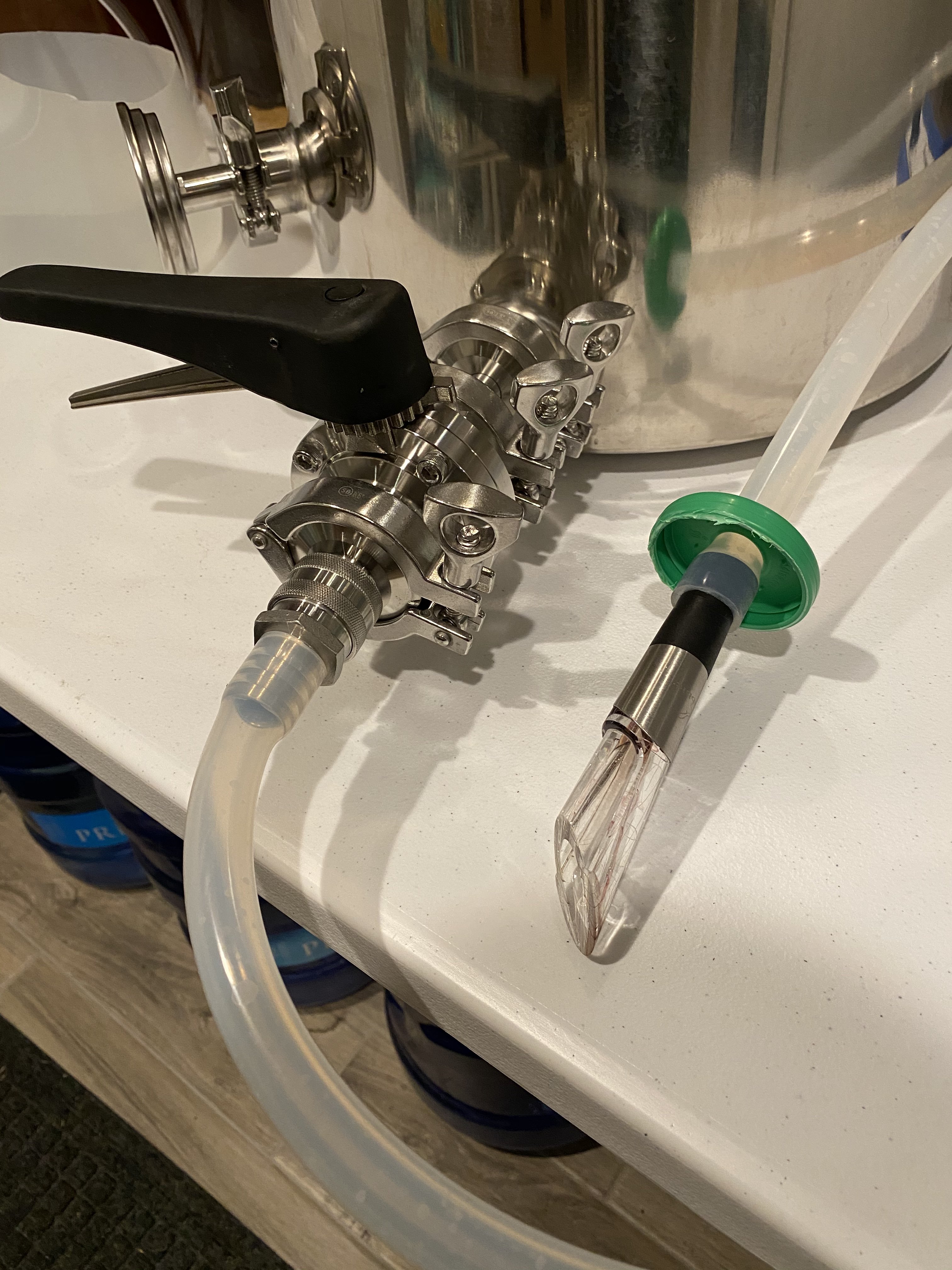

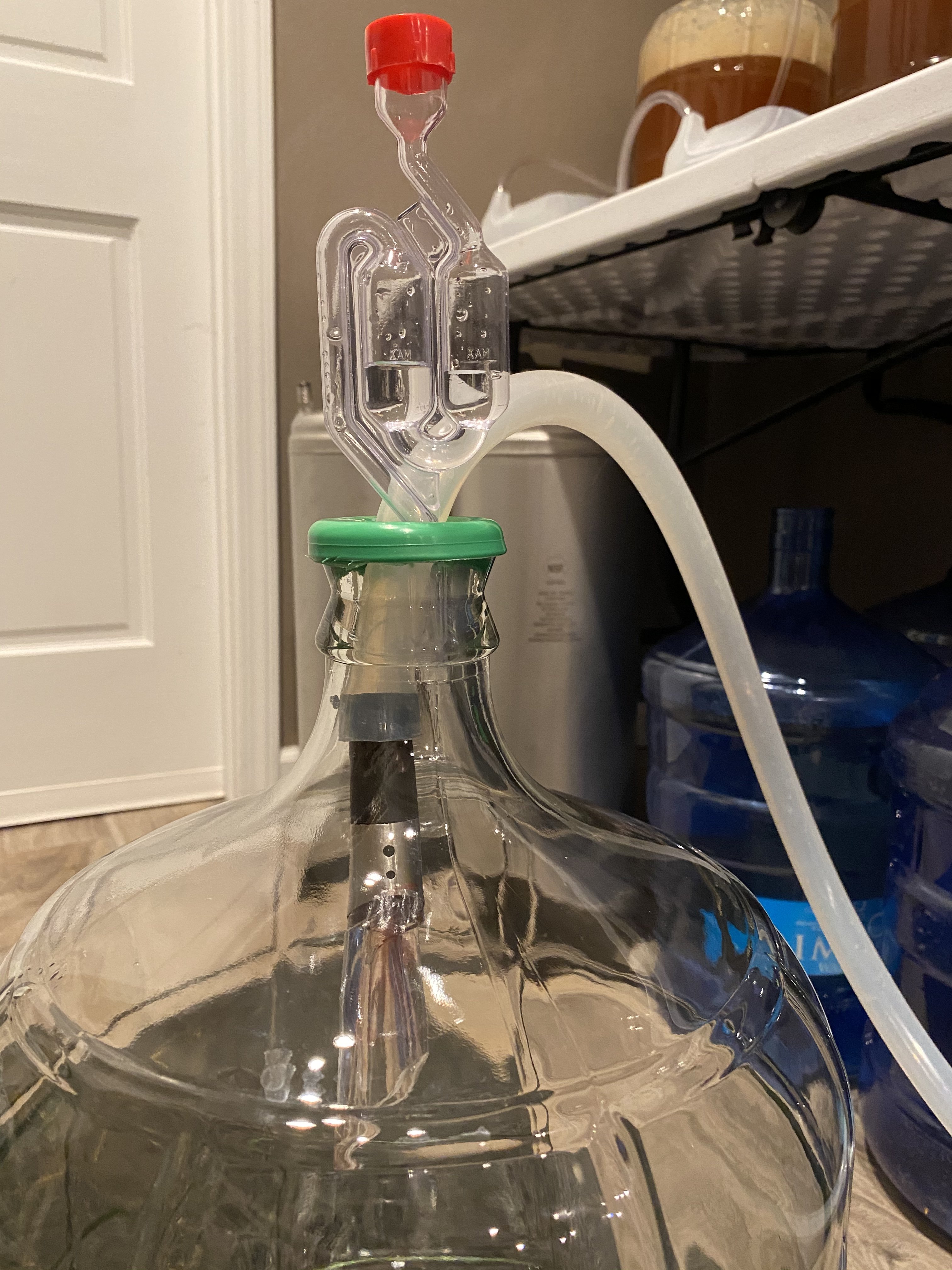

That got me thinking... the silicone hose coming from my brew kettle just happens to fit perfectly through the top of the plastic caps that come on 5 gallon water jugs from Wal Mart. Those plastic caps just happen to fit perfectly on top of glass carboys. Here’s the fun part. I can jam an aerator made for dry red wine into the hose. If you’ve never used an aerator on a dry red, try a side by side with/without aerator.

I wonder if this would be a decent way to do closed transfer from my brew kettle to my primary glass carboy while also aerating the wort. Would be easy enough to vent the cap w an airlock. If the gravity/pressure didn’t work out I suppose I could just leave the cap out of it. I think it would take forever, but I use an immersion chiller to quickly get down to pitching temp, and could close up the whole thing and let it take it’s time. Thoughts??

That got me thinking... the silicone hose coming from my brew kettle just happens to fit perfectly through the top of the plastic caps that come on 5 gallon water jugs from Wal Mart. Those plastic caps just happen to fit perfectly on top of glass carboys. Here’s the fun part. I can jam an aerator made for dry red wine into the hose. If you’ve never used an aerator on a dry red, try a side by side with/without aerator.

I wonder if this would be a decent way to do closed transfer from my brew kettle to my primary glass carboy while also aerating the wort. Would be easy enough to vent the cap w an airlock. If the gravity/pressure didn’t work out I suppose I could just leave the cap out of it. I think it would take forever, but I use an immersion chiller to quickly get down to pitching temp, and could close up the whole thing and let it take it’s time. Thoughts??

Last edited:

Nick&Worty

Well-Known Member

- Joined

- Sep 2, 2020

- Messages

- 282

- Reaction score

- 440

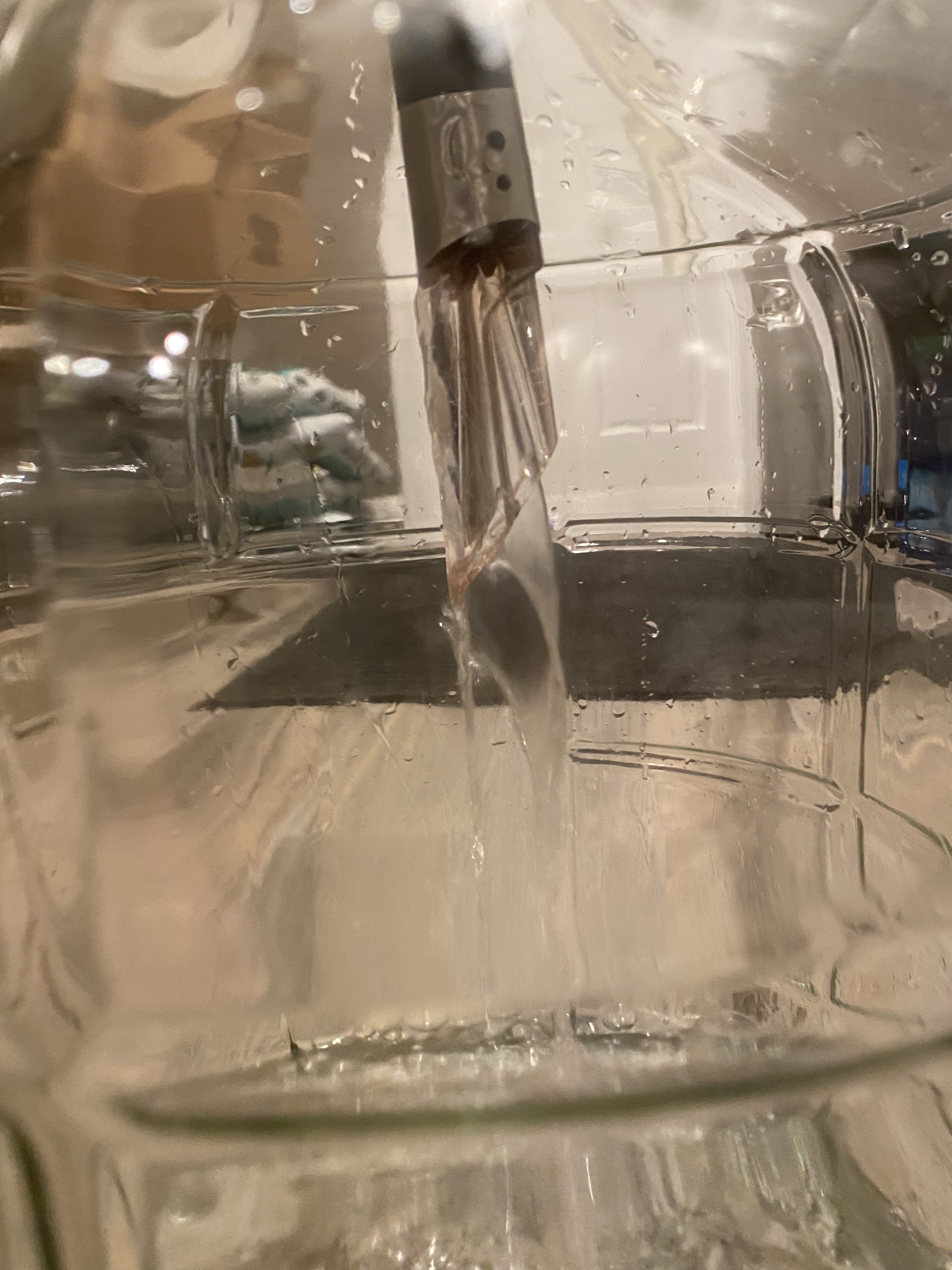

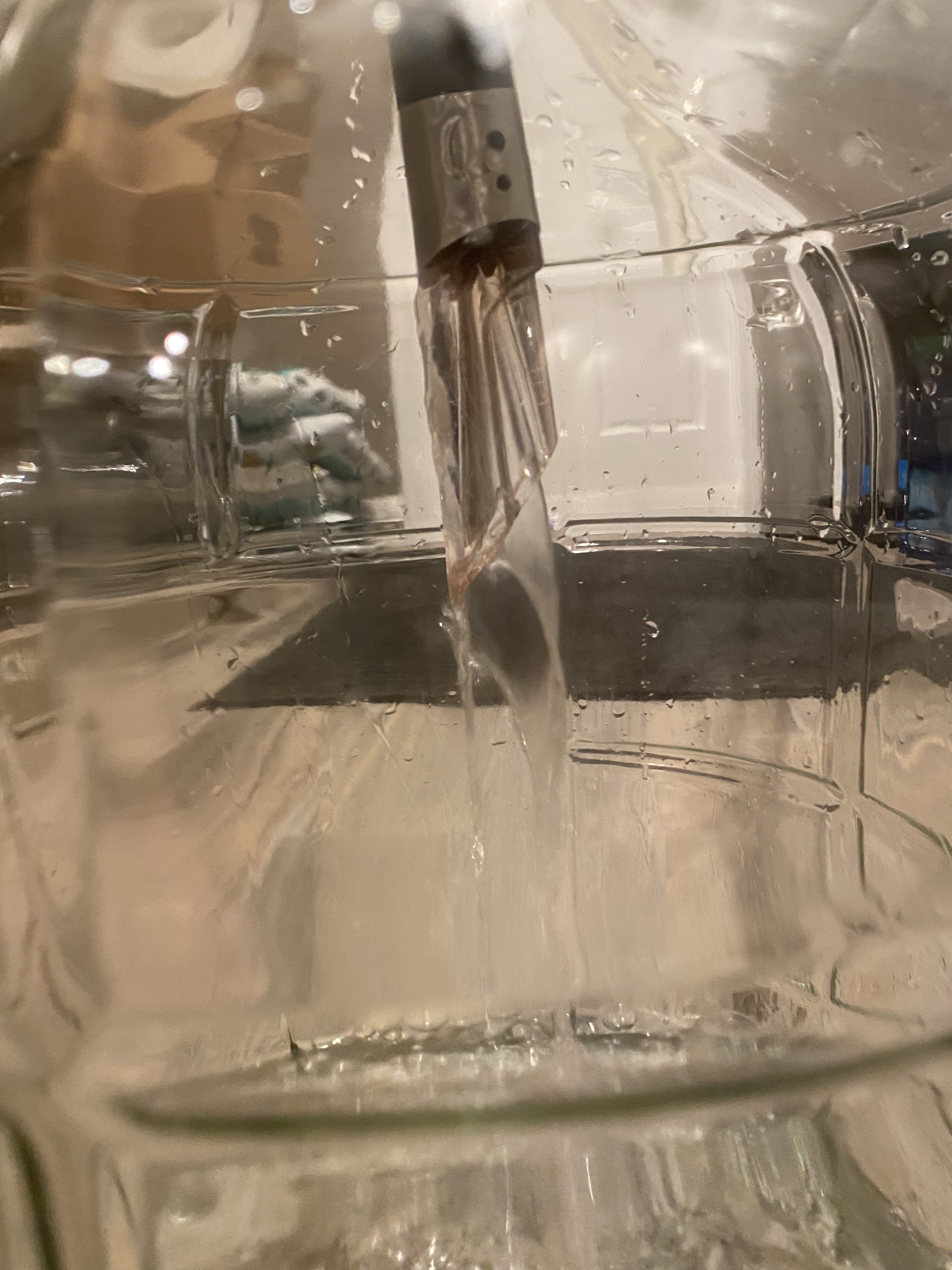

Water test worked. Not nearly as slow as I suspected it would be. Wonder if wort will clog it...

Last edited:

I would say your approach shown is better than shaking a glass carboys which can be dangerous. I would be a little worried about the aerator slipping out and having to mess around to get it out of my wort.Alright friends, it’s MacGyver time again! I’ve got an idea, and I want to know what you think. Like I mentioned in a previous post, I ran out of O2 last time I brewed, and had to resort to shaking the crap out of the carboy. That fermentation seems to have gone well, and I’ve read conflicting things on whether my O2 wand is even that useful for standard gravity ales and such.

That got me thinking... the silicone hose coming from my brew kettle just happens to fit perfectly through the top of the plastic caps that come on 5 gallon water jugs from Wal Mart. Those plastic caps just happen to fit perfectly on top of glass carboys. Here’s the fun part. I can jam an aerator made for dry red wine into the hose. If you’ve never used an aerator on a dry red, try a side by side with/without aerator.

I wonder if this would be a decent way to do closed transfer from my brew kettle to my primary glass carboy while also aerating the wort. Would be easy enough to vent the cap w an airlock. If the gravity/pressure didn’t work out I suppose I could just leave the cap out of it. I think it would take forever, but I use an immersion chiller to quickly get down to pitching temp, and could close up the whole thing and let it take it’s time. Thoughts??View attachment 701946View attachment 701947View attachment 701955

Some yeast do OK with little added oxygen and other need more. I used to just stir the crap out my wort for a couple minutes and most were good with that but I had sometime it would take a while a some yeasts to get going. I use a wand and bottled oxygen and get more consistent results now.

Defrosted the beer fridge at the city house.

Brewed my Red Rye. Plate chiller got the wort down to 90F on its way into the fermenter. I am sure it can do better, especially because the water goes through an ice bath before the plate chiller. I may have to basically drip the wort from the kettle, as I thought I had a really slow flow this time.

Other brewers make this work, not sure why I can’t.

Chilled to pitch temp, O2’d it and added yeast, so I have high hopes for the beer even so.

Other brewers make this work, not sure why I can’t.

Chilled to pitch temp, O2’d it and added yeast, so I have high hopes for the beer even so.

Nick&Worty

Well-Known Member

- Joined

- Sep 2, 2020

- Messages

- 282

- Reaction score

- 440

Brewed my Red Rye. Plate chiller got the wort down to 90F on its way into the fermenter. I am sure it can do better, especially because the water goes through an ice bath before the plate chiller. I may have to basically drip the wort from the kettle, as I thought I had a really slow flow this time.

Other brewers make this work, not sure why I can’t.

Chilled to pitch temp, O2’d it and added yeast, so I have high hopes for the beer even so.

I haven't picked up a plate chiller yet, just use immersion, but from what I've read that sounds off. Which plate chiller do you use? Wondering about orientation, flow direction, etc.

- Joined

- Jul 10, 2020

- Messages

- 73

- Reaction score

- 321

Started 5 gallons of barleywine. Happy with SG at 1.087 and strong Fermentation began within 7 hours. Timing this batch to add in a 5 gallon bourbon barrel. 8-12 months to wait on this one. Brewed a 1 gallon stout. Have had Evan Williams sitting on oak chips to add later on this one. Finally, kegged 3 gallons And bottled the rest of a bourbon barrel stout that has been resting in a barrel waiting for right time. Still some aging. Hoping for December.

Dudadiesel 12. I’m following the instructions, so there will be another chance this coming weekend to see if I can throttle back the wort even more. Los Angeles groundwater is warm, but I would think that the prechill ice bath would help more.I haven't picked up a plate chiller yet, just use immersion, but from what I've read that sounds off. Which plate chiller do you use? Wondering about orientation, flow direction, etc.

RIP old friend and welcome to the gates of beer heaven.I put my dying keezer to rest today. My second keezer, it didn't quite make it to its 9th birthday.

It was a great machine, reliable as hell (until it wasn't), always good pours...

View attachment 701855

Hoping the next build will be a little bit cleaner in the back...

View attachment 701856

...but it's definitely going to be much less cramped inside.

View attachment 701857

Totally stripped it clean of parts for the new build.

I'll eventually stuff the carcass in the back of my Durango and haul it to the same store that sold me its replacement for disposal.

View attachment 701858

View attachment 701859

Meanwhile...K3 gets ever closer to "done"...

View attachment 701860

Cheers!

Prost

Yep chilling water running fast wort running very slow. You can put the plate chiller in ice too.I haven't picked up a plate chiller yet, just use immersion, but from what I've read that sounds off. Which plate chiller do you use? Wondering about orientation, flow direction, etc.

- Joined

- May 24, 2020

- Messages

- 105

- Reaction score

- 141

Swapped out the cheap steepless clamps for hose clamps on CO2 and beer side lines (the first set of clamps that came with the dual tap regulator all leaked CO2 and beer, so I wasn't going down that road again). Kegged a Blacked Brutal Bitter.

Kegged 10 gallons of my German Leicht Altbier. I was trying to make a light Altbier that still had a ton of flavor despite trying to hit 3.8% ABV, for a crushable flavorful beer. I hit my target on the first try. The flat sample tasted amazing and I can't wait until it's carbed! Also made a Perry cider today with the wife. She loves those.

John

John

Started the second propagation on my yeast starter and worked out the water profile for my Scottish Export

I was going to brew today but I woke up with a sore back so I put it off a day. I let the RO system run a bit too long and now I have 50 gal and only need 30. Oh well I'll drink the rest.

I was going to brew today but I woke up with a sore back so I put it off a day. I let the RO system run a bit too long and now I have 50 gal and only need 30. Oh well I'll drink the rest.

- Joined

- Feb 19, 2017

- Messages

- 959

- Reaction score

- 1,217

Made v12 of the Machine House Mild clone attempt. Getting closer but not there yet. Used WLP085 vs a straight fullers to bring down the FG. [Also, I have the fast ferment 3 gallon conical as my yeast propagation unit, and it's time for more 85 yeast.]

Tried my first rye flour mash. I had seen a recipe (maybe on these boards for 3# 6-row and 3# rye flour?) that looked simple but good. And I have a 25# bag of rye flour in the garage for bread that I am very slowly working my way thru. Sooooooo, why not do a 6-row, rye flour ale he wonders....Found the note to self to brew this, and inconveniently no link or notes to the actual recipe. Hacked together a half batch and see how it comes out in a week or three.

Yesterday I pitched an OG 1038 Irish Oat Stout on top of an ordinary bitter west yorkshire yeast cake. (I typically don't use w yorkie for Irish stouts but it was a fresh yeast cake and the only clean fermenter, so what the hell it's experiment with yeast time!). 24 hours later it had dropped to 1018, so into the keg with a floating dip tube and spunding valve it went.

Tried my first rye flour mash. I had seen a recipe (maybe on these boards for 3# 6-row and 3# rye flour?) that looked simple but good. And I have a 25# bag of rye flour in the garage for bread that I am very slowly working my way thru. Sooooooo, why not do a 6-row, rye flour ale he wonders....Found the note to self to brew this, and inconveniently no link or notes to the actual recipe. Hacked together a half batch and see how it comes out in a week or three.

Yesterday I pitched an OG 1038 Irish Oat Stout on top of an ordinary bitter west yorkshire yeast cake. (I typically don't use w yorkie for Irish stouts but it was a fresh yeast cake and the only clean fermenter, so what the hell it's experiment with yeast time!). 24 hours later it had dropped to 1018, so into the keg with a floating dip tube and spunding valve it went.

BrewMan13

Whole Nother Level Brewing

I was a busy boy yesterday: brewed up a milk stout, changed out the bad posts on a couple kegs, and kegged the pumpkin ale. Decided to prime it in the keg with sugar, since I'm low on CO2, and this isn't going on tap anyway. Due to the graciousness of the owner of my Friday night hangout spot, I'll be able to can it, which will make giving it way easier.

Yes! Throw it right into the ice water.Yep chilling water running fast wort running very slow. You can put the plate chiller in ice too.

Yes! Throw it right into the ice water.

Well, all right then! Looking forward to seeing if I can do this without screwing it up. Is there an issue with leakage on the wort hoses when submerged? They don't leak now, but new system, new rules, sometimes.

Kegged my two IPAs. One clocks in at 6.7% & the other at 7.1%. Same beer different yeast strains. The POG yeast is the lower ABV beer but the sample was more fruit forward on the tongue and nose. The other was a yeast built up from OH (thinking it’s a London Ale III strain) is the higher ABV sample tasted pretty good, not as fruity as the POG strain. Set the CO2 to 35psi and hope it will be ready in a few days to share.

My plate chiller will get warm/hot out of ice or cold water. Just make sure your fittings are secure. Use clamps or whatever. I pump it all through with one of these: it is a 12 volt solar circulation pump for hot/boiling water 2.1 gallons per minute. From Amazon 26.50. I added a 12 volt dimmer from Amazon $6 and I can adjust the flow anywhere that I want it. I did chsnge out the fittings to stainless steel. The pump is submersible to 123F, but transfers boiling fluid with no problem. You also have to prime it (easy).Well, all right then! Looking forward to seeing if I can do this without screwing it up. Is there an issue with leakage on the wort hoses when submerged? They don't leak now, but new system, new rules, sometimes.

I actually use two of these....one on the cooling water and one on the wort.

Do a practice run with hot water...no wasted beer

]

Last edited:

Pulled FG samples of the Bullwinkle Brown and Amber Blonde that were brewed a couple of weeks ago.

Fish84

Active Member

- Joined

- Jan 14, 2019

- Messages

- 25

- Reaction score

- 21

If you’ve never tried it. I recommend Holly’s Christmas ale. Bottled mine todaySipping on some homebrew while I ponder on this year's Holiday Ale recipe. Planning on bottling the whole batch this year so I need to get going on it in the next two weeks. I've done the last three years Holiday Ale with an american strong base beer while playing with the spice additions. This year I might add a touch of chocolate malt with some flaked barley to up the mouthfeel, and up the spice additions to a full 22oz bottle filled with capn morgan rum and a TON of spice, this year to include our usual cinnamon, nutmeg, allspice, pumpkin pie spice, and what I have left of dried orange peel. This year going for something close to Old Fezziwig but with a knock-your-ugly-holiday-socks-off spice kick, just for the heck of it. Also too much fun to sit here and think about it. Also want to amaze my perfect sister who never fails to find a holiday ale at the local store to challenge my brewing skills.

https://www.homebrewtalk.com/forum/threads/holly-christmas-ale.145580/

Pulled FG samples of the Bullwinkle Brown and Amber Blonde that were brewed a couple of weeks ago.

View attachment 702241

I am impressed that you have two hydrometers functioning at the same time...they seem to not make it too long....

Nick&Worty

Well-Known Member

- Joined

- Sep 2, 2020

- Messages

- 282

- Reaction score

- 440

Mine are straight suicidal.I am impressed that you have two hydrometers functioning at the same time...they seem to not make it too long....

One of those is the one I started with almost 10 years ago. The other is the spare that I’ve never needed. Never broken one.

If you have good connections there will be no problem. I had a leak one time and spotted it quickly when the ice water turned yellow. I brewed 13.5 gal of Scottish Export today. Came in at 1.065 so I'll add adjusted RO water to bring it down to style at 1.047.Well, all right then! Looking forward to seeing if I can do this without screwing it up. Is there an issue with leakage on the wort hoses when submerged? They don't leak now, but new system, new rules, sometimes.

I really like your pump setupIf you have good connections there will be no problem. I had a leak one time and spotted it quickly when the ice water turned yellow. I brewed 13.5 gal of Scottish Export today. Came in at 1.065 so I'll add adjusted RO water to bring it down to style at 1.047.View attachment 702268View attachment 702269View attachment 702270

If you have good connections there will be no problem. I had a leak one time and spotted it quickly when the ice water turned yellow. I brewed 13.5 gal of Scottish Export today. Came in at 1.065 so I'll add adjusted RO water to bring it down to style at 1.047.View attachment 702268View attachment 702269View attachment 702270

Amazing setup, floor drain included!

Similar threads

- Replies

- 21

- Views

- 834

- Replies

- 89

- Views

- 4K