iijakii

Well-Known Member

Guess I should start a build thread. First I'd like to thank JKarp, PJ, Ischavio, Kal, BobbyM and many others for answering a lot of dumb questions. Couldn't have even began to think about undertaking this without PJ's diagrams or Kal's website.

What started this all was seeing JKarps's Countertop Brutus20. I wanted it. But, I wanted a larger size. PJ helped me with the idea of using the spa-panel and dryer-outlet for a 240v 30amp power source. Giggity. The build kept morphing a bit after seeing Kal's website et cetera. My simple CB20 idea turned into something else... with a much bigger cost . For those of you unfamiliar with the Brutus 20 concept it's a two-vessel full volume, no sparge system which I will be recirculating during the entire mash. I'm hoping I get ~75% efficiency like JKarp and others, but if I don't I plan on just mashing 1-2 gallons shy of total volume and doing a psuedo cold-water batch sparge to rinse some of them sugar goodnesses.

. For those of you unfamiliar with the Brutus 20 concept it's a two-vessel full volume, no sparge system which I will be recirculating during the entire mash. I'm hoping I get ~75% efficiency like JKarp and others, but if I don't I plan on just mashing 1-2 gallons shy of total volume and doing a psuedo cold-water batch sparge to rinse some of them sugar goodnesses.

First I started building a brewstand. I was wanting to keep it simple with one pump, but I wanted it to look nice. I looked into modifying a stainless table, but basically don't have any welding skills or fancy tools.

What I did was make mitred collars with 1x6 and then attach them to the 4x4s. Once I did that I attached 2v4s on the insides of the 1x6s for a brace to attach the table top since I was wanting it flush. Worked pretty well. There's a few gaps but I don't have access to a table saw nor planar so oh well.

Used Red Mahogany stain, and am going to polyurethane it this weekend. Will be painting the legs black. The one raised leg, by the way, is so I can attach the control-panel with a swinging TV wall mount.

Got the panel face and three receptacles cut at a waterjet facility for $70. Cheaper than buying holesaws...

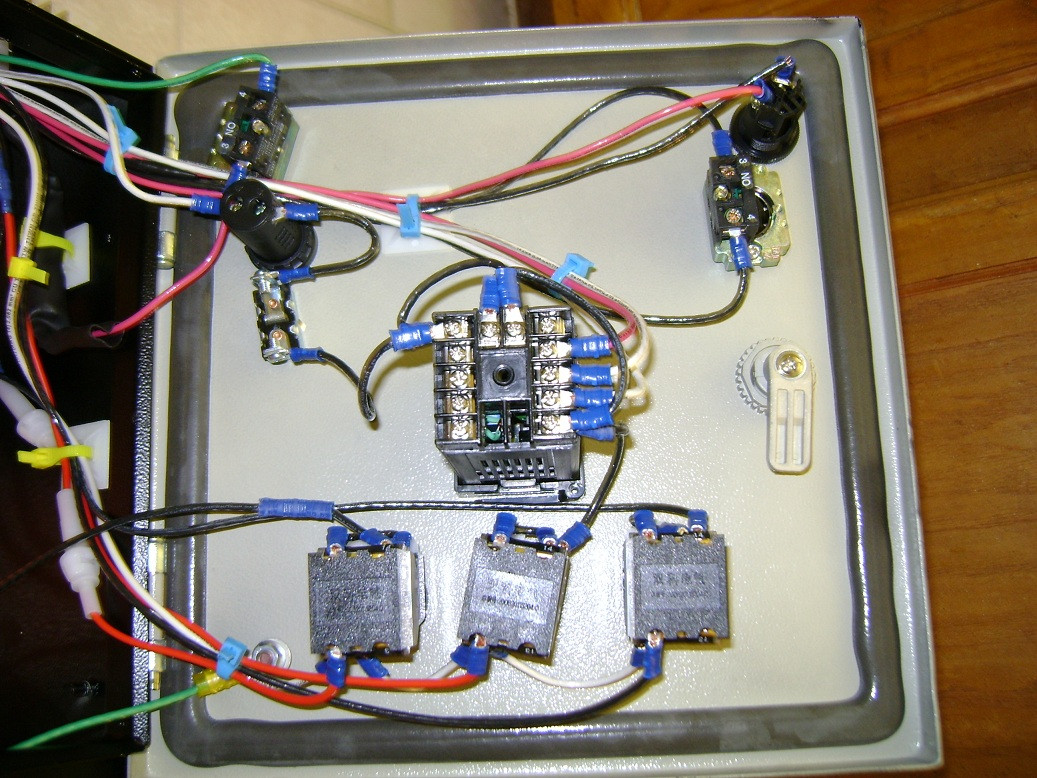

Keyed-switch is the power on-off; and power indicator LED above it. Then there's a momentary push-button ESTOP, alarm and toggle to turn the alarm off. The three bottom push-buttons are for PID, Pump and Element power.

Here's the main thing with my build I'm unhappy with so far: the heatsink. I didn't have a drive long enough to drill down through the fins, so I did it from the bottom side. Well, I suck at drilling holes apparently and two of them didn't align well. The screw heads get stuck on the fins and don't go down all the way. A bit of an eye sore.

Then the other mishap is the XLR panelmount here being a bit crooked. I blame dull drillbits and tough metal but maybe it's me just being a rookie and not using my punch enough.

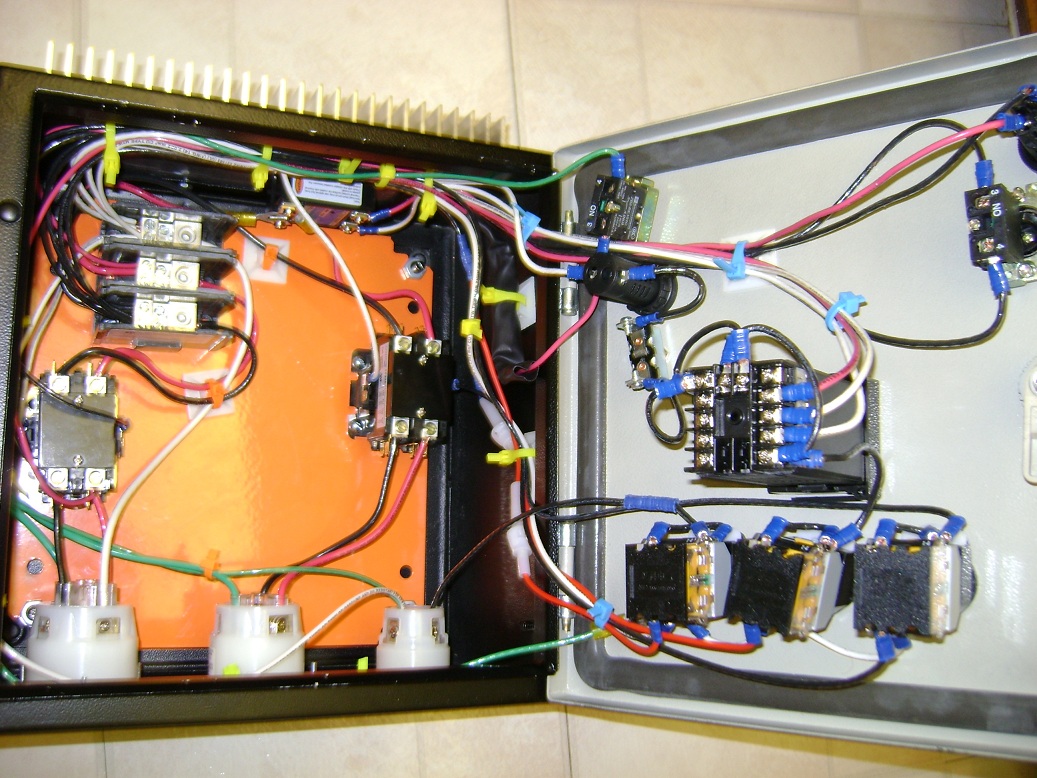

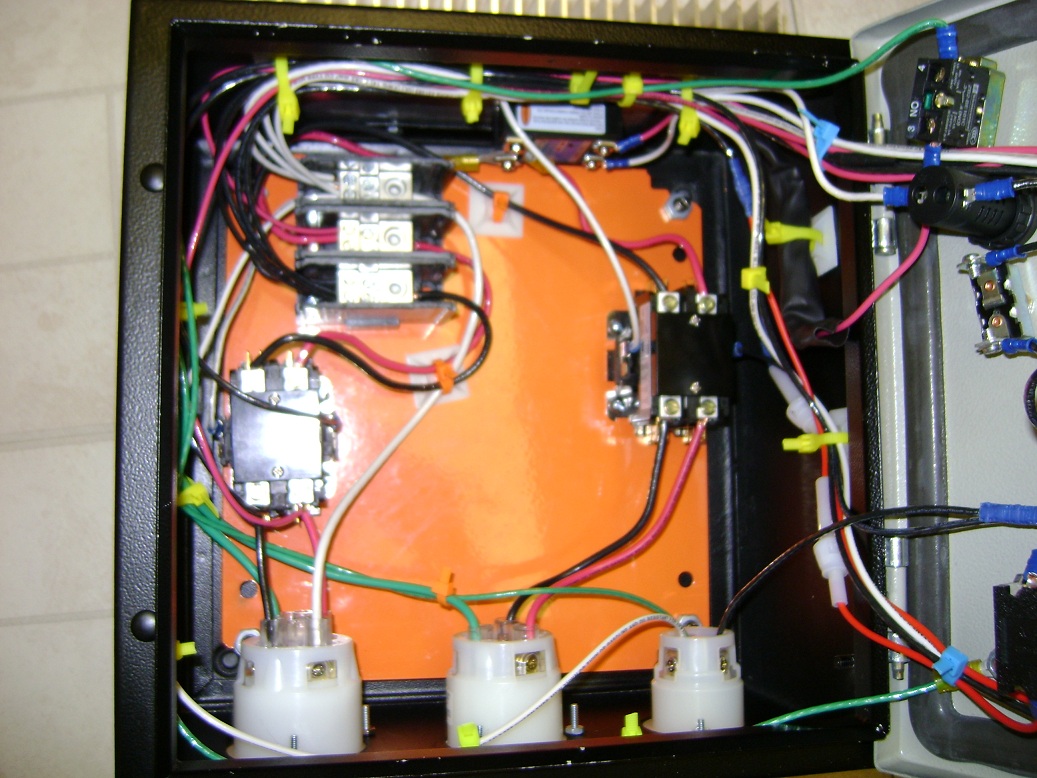

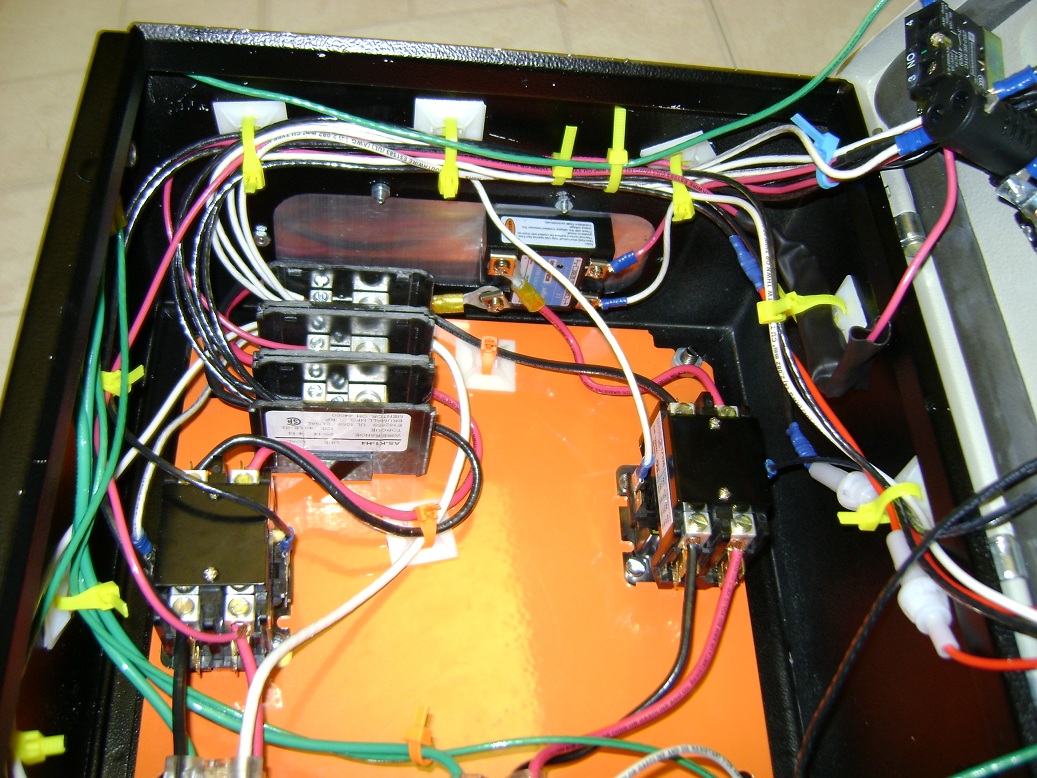

I guess that's about it. Maybe I should have waited til I was finished to make the thread. I'm currently about 40% finished with wiring. I actually ran out of 14ga black so I'm writing this post instead of working now.

Made a wiring mistake that I caught pretty early. I had the key-switch which works the contactor coil being powered from the distro blocks which are post-contactor. Don't have enough wire to fix it tonight though. Frustrating.

What started this all was seeing JKarps's Countertop Brutus20. I wanted it. But, I wanted a larger size. PJ helped me with the idea of using the spa-panel and dryer-outlet for a 240v 30amp power source. Giggity. The build kept morphing a bit after seeing Kal's website et cetera. My simple CB20 idea turned into something else... with a much bigger cost

First I started building a brewstand. I was wanting to keep it simple with one pump, but I wanted it to look nice. I looked into modifying a stainless table, but basically don't have any welding skills or fancy tools.

What I did was make mitred collars with 1x6 and then attach them to the 4x4s. Once I did that I attached 2v4s on the insides of the 1x6s for a brace to attach the table top since I was wanting it flush. Worked pretty well. There's a few gaps but I don't have access to a table saw nor planar so oh well.

Used Red Mahogany stain, and am going to polyurethane it this weekend. Will be painting the legs black. The one raised leg, by the way, is so I can attach the control-panel with a swinging TV wall mount.

Got the panel face and three receptacles cut at a waterjet facility for $70. Cheaper than buying holesaws...

Keyed-switch is the power on-off; and power indicator LED above it. Then there's a momentary push-button ESTOP, alarm and toggle to turn the alarm off. The three bottom push-buttons are for PID, Pump and Element power.

Here's the main thing with my build I'm unhappy with so far: the heatsink. I didn't have a drive long enough to drill down through the fins, so I did it from the bottom side. Well, I suck at drilling holes apparently and two of them didn't align well. The screw heads get stuck on the fins and don't go down all the way. A bit of an eye sore.

Then the other mishap is the XLR panelmount here being a bit crooked. I blame dull drillbits and tough metal but maybe it's me just being a rookie and not using my punch enough.

I guess that's about it. Maybe I should have waited til I was finished to make the thread. I'm currently about 40% finished with wiring. I actually ran out of 14ga black so I'm writing this post instead of working now.

Made a wiring mistake that I caught pretty early. I had the key-switch which works the contactor coil being powered from the distro blocks which are post-contactor. Don't have enough wire to fix it tonight though. Frustrating.