thelorax121

Well-Known Member

So I am putting the finishing touches on my new single tier, 1 pump, keggle based system and I am looking for some feedback in regards to chilling and whirlpooling. I am looking at two options at the moment:

One

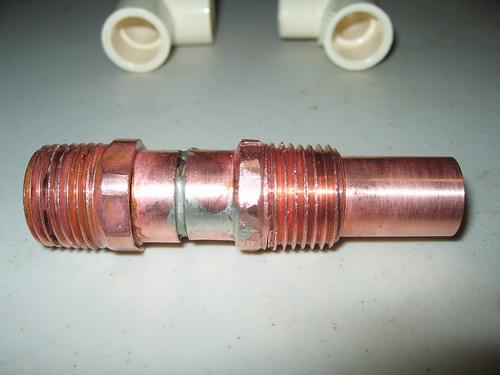

I have a CFC that I have not used yet, but I have seen that some people use their pump to draw from the kettle valve, pump the hot wort through a CFC then back through a whirl-pooling mechanism (I plan on having a whirlpool valve installed directly on the side of the pot with a weldless fitting and male cam lock connect) in the kettle and repeating this process until the wort is at pitching temps, letting the trub settle, then running clear wort to the fermenter. My concern with this is that the pump flow will be drastically reduced by running from 1/2" silicone tubing to 25 ft of 3/8" tubing significantly reducing the whirlpool effect and slowing the chilling down, has anyone experienced this?

Option Two

Use a 50ft 1/2" IC with the aforementioned kettle installed whirlpool arm. What I like about this option is that it gives me the option of using a bucket of ice water and a small aquarium pump to circulate the cooling water through the IC for lager and/or hot weather brewing, as well as saving water. My question with this method however is will having the whirlpool arm situated on the outside of the IC affect either the whirlpool effect or cooling rates negatively, as all the jamil-based whirlpooling ICs seem to have the arm inside the coils of the chiller?

Sorry for the length folks, and thanks for the help!

One

I have a CFC that I have not used yet, but I have seen that some people use their pump to draw from the kettle valve, pump the hot wort through a CFC then back through a whirl-pooling mechanism (I plan on having a whirlpool valve installed directly on the side of the pot with a weldless fitting and male cam lock connect) in the kettle and repeating this process until the wort is at pitching temps, letting the trub settle, then running clear wort to the fermenter. My concern with this is that the pump flow will be drastically reduced by running from 1/2" silicone tubing to 25 ft of 3/8" tubing significantly reducing the whirlpool effect and slowing the chilling down, has anyone experienced this?

Option Two

Use a 50ft 1/2" IC with the aforementioned kettle installed whirlpool arm. What I like about this option is that it gives me the option of using a bucket of ice water and a small aquarium pump to circulate the cooling water through the IC for lager and/or hot weather brewing, as well as saving water. My question with this method however is will having the whirlpool arm situated on the outside of the IC affect either the whirlpool effect or cooling rates negatively, as all the jamil-based whirlpooling ICs seem to have the arm inside the coils of the chiller?

Sorry for the length folks, and thanks for the help!