mplutodh1

Well-Known Member

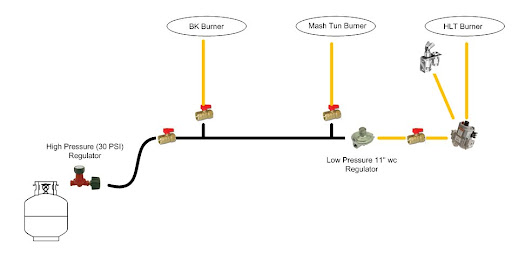

We're trying to figure out what regulator we need for our brewstand. We've been reading several posts on here that suggest having a 2 stage regulator - we'll need low pressure with 11 wc output. I've been looking but most are fairly low BTU ratings.

What would be a good regulator that will give us enough BTU to run a few burners?

We aren't direct firing our MLT although we do have a burner setup in case we need it). We're using 3 Banjo burners as well.

What would be a good regulator that will give us enough BTU to run a few burners?

We aren't direct firing our MLT although we do have a burner setup in case we need it). We're using 3 Banjo burners as well.