I am in the process of building a 3 keg pump driven system and was planning on direct firing my mash tun. I don't think I'm looking to build a RIMS or HERMS as of now and was wondering if it's possible to direct fire a mash tun without scorching the grain?

My plan is to fire the HLT and BK with the huge Bayou Classic BG14 burners, while firing the MLT with the smaller BG12 burner. I was planning on recirculating the mash through my electric pump and directly back into the MLT. Would this work? I suppose I could also recirculate my mash through my 50 ft wort chiller inside the HLT, but I'm mostly concerned with the amount of time it will take to raise the temperature of the liquid for a step mash without direct firing the MLT. Any thoughts or input on this?

Also, this may be a silly idea, but is it possible to put a false bottom ABOVE the ball valve in a keg? Would this create too much dead space or is this not even possible? I thought having the grain bed that high above the heat would help prevent scorching, but I'm just guessing at this point.

I purchased this item: http://morebeer.com/view_product/10073//Maximizer_for_Mash_Tun_Hot_Liquor_Tank the maximizer from MoreBeer in the hopes of using it in my 1/2 barrel keg with false bottom. Now I see this might not work and I probably need a standard false bottom with regular fittings but am concerned about scorching if the grain is that close to the heat source.

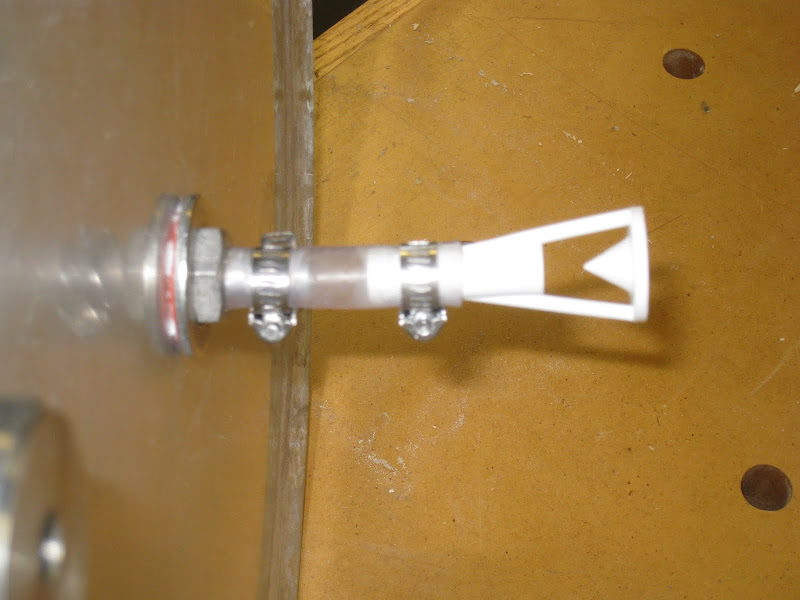

Finally, is it possible to recirculate the mash back through your sparge arm...like a stainless rotating one? I am looking for options of what type of 'valve' to use to drop the mash back into the MLT.

My plan is to fire the HLT and BK with the huge Bayou Classic BG14 burners, while firing the MLT with the smaller BG12 burner. I was planning on recirculating the mash through my electric pump and directly back into the MLT. Would this work? I suppose I could also recirculate my mash through my 50 ft wort chiller inside the HLT, but I'm mostly concerned with the amount of time it will take to raise the temperature of the liquid for a step mash without direct firing the MLT. Any thoughts or input on this?

Also, this may be a silly idea, but is it possible to put a false bottom ABOVE the ball valve in a keg? Would this create too much dead space or is this not even possible? I thought having the grain bed that high above the heat would help prevent scorching, but I'm just guessing at this point.

I purchased this item: http://morebeer.com/view_product/10073//Maximizer_for_Mash_Tun_Hot_Liquor_Tank the maximizer from MoreBeer in the hopes of using it in my 1/2 barrel keg with false bottom. Now I see this might not work and I probably need a standard false bottom with regular fittings but am concerned about scorching if the grain is that close to the heat source.

Finally, is it possible to recirculate the mash back through your sparge arm...like a stainless rotating one? I am looking for options of what type of 'valve' to use to drop the mash back into the MLT.