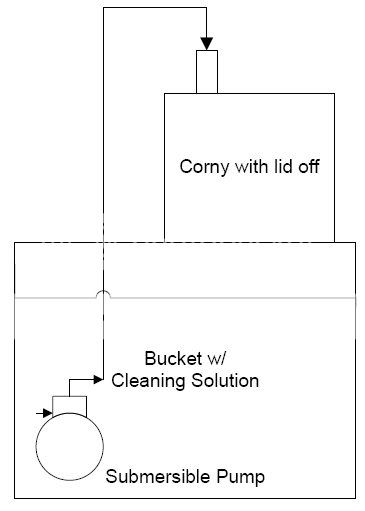

So I am off work for about 8 more weeks and I wanted to design and put together a keg washer while I am out, to be able to wash and sanitize both ball lock and sanke kegs. I am thinking one w/ a 4500 or 5500 watt heating element, a holding tank w/ float switch and a pump, all temp controlled off my system w/ low level cut off. I am looking for the actual design and flow of the washer itself. I will figure out the electrical as thats not a problem, electrically there isn't much I can't do and as for welding I do that too so putting this together is not really a problem. I have several stainless tanks I can use and I will also buy a pump for this.

I want it to be small compact and fairly easy to store. Any ideas guys? Anybody ever seen a keg washer? I am not even sure what kind of chemicals I would use in a washer?

Anyway let the design ideas rip.

Cheers

JJ

I want it to be small compact and fairly easy to store. Any ideas guys? Anybody ever seen a keg washer? I am not even sure what kind of chemicals I would use in a washer?

Anyway let the design ideas rip.

Cheers

JJ