jrmorrill

Member

I am starting construction on my All-Grain system and so far this is my plan:

Stage 1: Gravity Fed System

The Parts:

HLT (Hot Liquor Tank)

I used the excellent tutorial here for using 10 gallon coolers for my HLT and MLT.

10 gallon Rubbermaid/Gott cooler ≈ $45

Full port ball valve parts ≈ $30

1500 Watt water heating element ≈ $10

I am planning on wiring the heating element to a 120v outlet plug with a switch to turn it on and off. I can manually monitor the temperature of the HLT and turn it on as needed. I got the idea for using a water heater element from the powers brewery system.

TOTAL ≈ $85

MLT (Mash Lauder Tun)

10 gal Rubbermaid/Gott cooler - $45

Full port ball valve parts - $30

(I already bought all these parts from Home Depot today! I will be updating with pics at some point.)

TOTAL ≈ $75

Boiling Kettle

50 quart (12.5 gal) Aluminum Stock Pot - $70 (including taxes, shipping and handling)

Full port ball valve parts - Not sure but probably around $30

Wort Chiller ≈ $50? (Building this out of copper tubing and fittings.)

TOTAL ≈ $150

Misc. Items

These are some items we will probably need to put all the pieces together. I haven't done all the research yet but so far it seems like these will all be necessary.

Hoses or copper tubing - ? (We will need food grade, high temp hoses or copper tubing to transfer water from the HLT to the MLT and wort from the MLT to the Boiling Kettle)

Sparge arm - ?

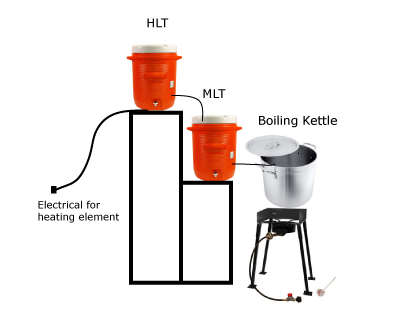

Framing Assembly - ? This is our "staircase-like" stand where HLT, MLT and Boiling Kettle will be sitting. See the image below for a possible setup.

Propane Burner - ? We can probably get away with some kinda burner meant for camping. I found a King Kooker model at Walmart for like $40. My parents actually have one that we could use. It's a double burner but it'll work just fine.

Mash Paddle ≈ $5 (We can cut this thing outta some nice wood ourselves.)

STAGE 1 TOTAL ≈ $350

I priced out similar setups for over $700 so I am pretty happy with this one. I know it's not the absolute cheapest way to go but I think it gives up lots of room for upgrading to a HERMS system in the future (Which happens to be my stage 2 plan hehe!!)

Stage 1: Gravity Fed System

The Parts:

HLT (Hot Liquor Tank)

I used the excellent tutorial here for using 10 gallon coolers for my HLT and MLT.

10 gallon Rubbermaid/Gott cooler ≈ $45

Full port ball valve parts ≈ $30

1500 Watt water heating element ≈ $10

I am planning on wiring the heating element to a 120v outlet plug with a switch to turn it on and off. I can manually monitor the temperature of the HLT and turn it on as needed. I got the idea for using a water heater element from the powers brewery system.

TOTAL ≈ $85

MLT (Mash Lauder Tun)

10 gal Rubbermaid/Gott cooler - $45

Full port ball valve parts - $30

(I already bought all these parts from Home Depot today! I will be updating with pics at some point.)

TOTAL ≈ $75

Boiling Kettle

50 quart (12.5 gal) Aluminum Stock Pot - $70 (including taxes, shipping and handling)

Full port ball valve parts - Not sure but probably around $30

Wort Chiller ≈ $50? (Building this out of copper tubing and fittings.)

TOTAL ≈ $150

Misc. Items

These are some items we will probably need to put all the pieces together. I haven't done all the research yet but so far it seems like these will all be necessary.

Hoses or copper tubing - ? (We will need food grade, high temp hoses or copper tubing to transfer water from the HLT to the MLT and wort from the MLT to the Boiling Kettle)

Sparge arm - ?

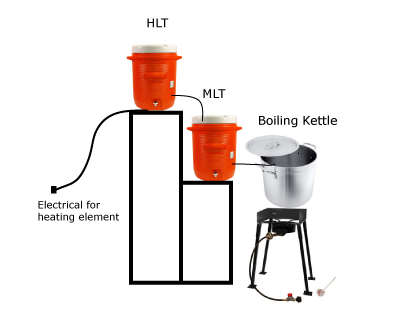

Framing Assembly - ? This is our "staircase-like" stand where HLT, MLT and Boiling Kettle will be sitting. See the image below for a possible setup.

Propane Burner - ? We can probably get away with some kinda burner meant for camping. I found a King Kooker model at Walmart for like $40. My parents actually have one that we could use. It's a double burner but it'll work just fine.

Mash Paddle ≈ $5 (We can cut this thing outta some nice wood ourselves.)

STAGE 1 TOTAL ≈ $350

I priced out similar setups for over $700 so I am pretty happy with this one. I know it's not the absolute cheapest way to go but I think it gives up lots of room for upgrading to a HERMS system in the future (Which happens to be my stage 2 plan hehe!!)