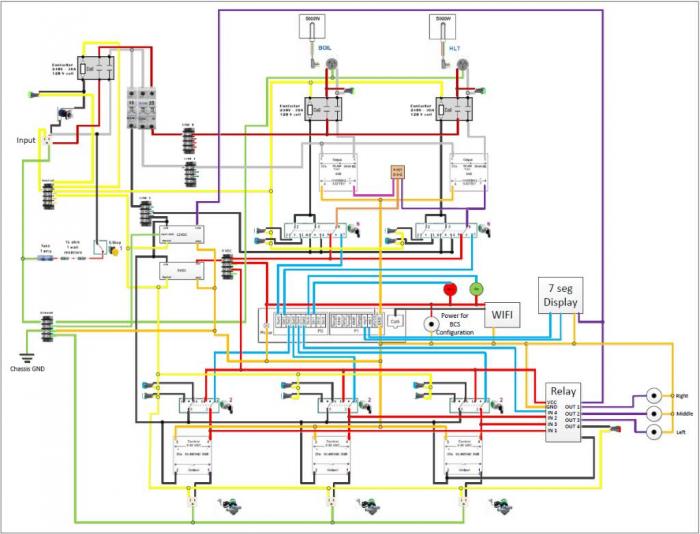

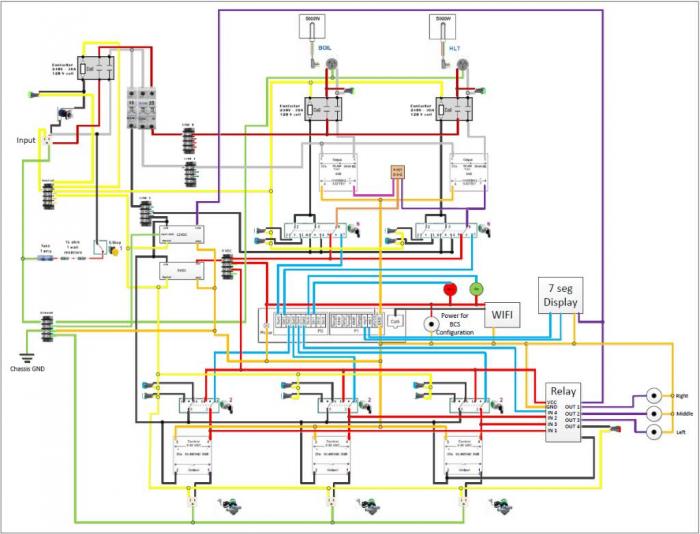

This topic has come up a few times and I have added my input as to how I would go about doing this. I recently built a new control panel and implemented this feature using a single P-FET transistor. My control panel is based around the BCS-460 but you could also do this same implementation if your panel uses multiple PID controllers. If you are using an arduino, BBB, R - pi or some other micro it could be implemented better with code.

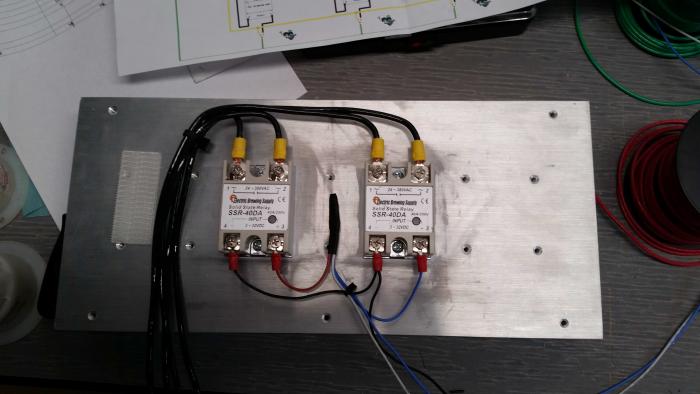

I brewed my first batch last Saturday and it worked quite well. My current system is a 2 vessel setup with a RIMS tube to control mash temps. I heat my strike and sparge water in my boil kettle. While I am mashing the RIMS duty cycle is pretty low because it doesn't need a lot of power to maintain mash temps. During this time the majority of the 1 second period can be used to heat my sparge water. Here is some pics of my wiring diagram of how to implemented this.

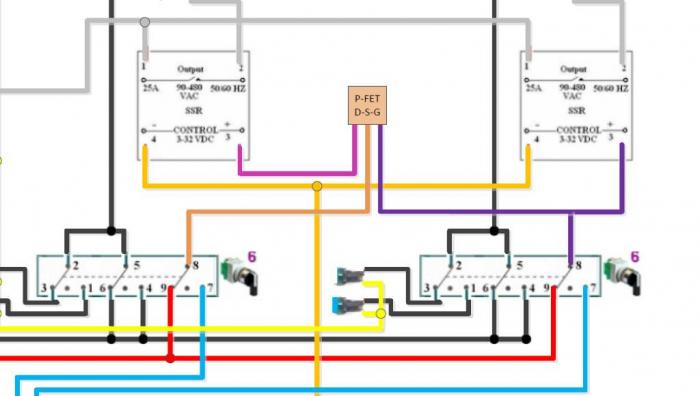

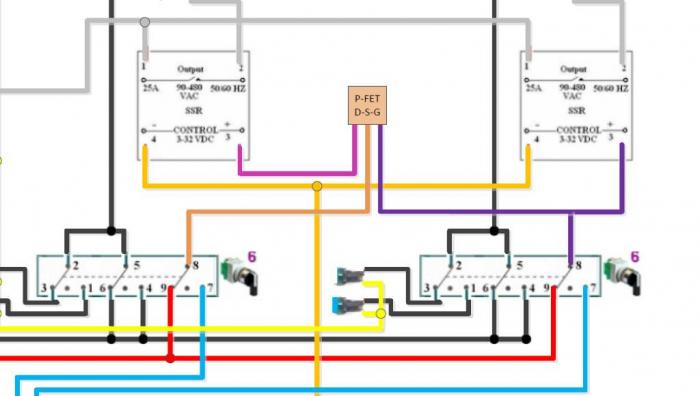

The D, G and S on the P-FET represent the drain, gate and source terminals. You could easily add a switch to change the priority. I may do this in the future so I can begin my cleaning cycle in the mash tun while I'm boiling. Currently the RIMS tube will always have priority over the boil kettle.

I brewed my first batch last Saturday and it worked quite well. My current system is a 2 vessel setup with a RIMS tube to control mash temps. I heat my strike and sparge water in my boil kettle. While I am mashing the RIMS duty cycle is pretty low because it doesn't need a lot of power to maintain mash temps. During this time the majority of the 1 second period can be used to heat my sparge water. Here is some pics of my wiring diagram of how to implemented this.

The D, G and S on the P-FET represent the drain, gate and source terminals. You could easily add a switch to change the priority. I may do this in the future so I can begin my cleaning cycle in the mash tun while I'm boiling. Currently the RIMS tube will always have priority over the boil kettle.