Skrimpy

Well-Known Member

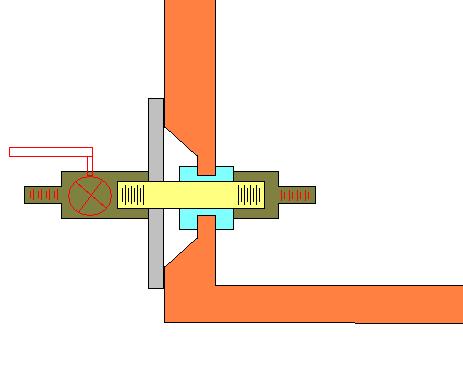

SS Washer can't be found for the time being:

I know it isn't a really good or correct solution but in a pinch (places that would have the stainless washer not being open the rest of the weekend), you can use a fourth washer on the outside with 3 of the 5/8" O-rings between the cooler and the ball valve and an extra O-ring between the cooler rubber seal and the inside barb.

No hose SS clamps or vinyl tube (they cost too much anyway):

Cut short pieces of the vinyl tube from the inside of the braided supply. Use the same way as someone else suggested for using the short pieces of vinyl tube in just the plug end and barb end of the braid. I've trimmed the nylon fibers as short as possible (Hopefully so short they won't have an effect) - Scratch that. The plug doesn't fit into that tube. Plug the braid for wieght then crimp then end.

If anyone sees anything seriously wrong with this (ie concerns about the nylon) let me know before I drink this stuff. I'm doing Edwort's Haus Pale Ale. I'm going to go with a little modification if I can. I will mash at around 155 for a little less body and a little more alcohol.

I know it isn't a really good or correct solution but in a pinch (places that would have the stainless washer not being open the rest of the weekend), you can use a fourth washer on the outside with 3 of the 5/8" O-rings between the cooler and the ball valve and an extra O-ring between the cooler rubber seal and the inside barb.

No hose SS clamps or vinyl tube (they cost too much anyway):

Cut short pieces of the vinyl tube from the inside of the braided supply. Use the same way as someone else suggested for using the short pieces of vinyl tube in just the plug end and barb end of the braid. I've trimmed the nylon fibers as short as possible (Hopefully so short they won't have an effect) - Scratch that. The plug doesn't fit into that tube. Plug the braid for wieght then crimp then end.

If anyone sees anything seriously wrong with this (ie concerns about the nylon) let me know before I drink this stuff. I'm doing Edwort's Haus Pale Ale. I'm going to go with a little modification if I can. I will mash at around 155 for a little less body and a little more alcohol.