As other have said - yup!

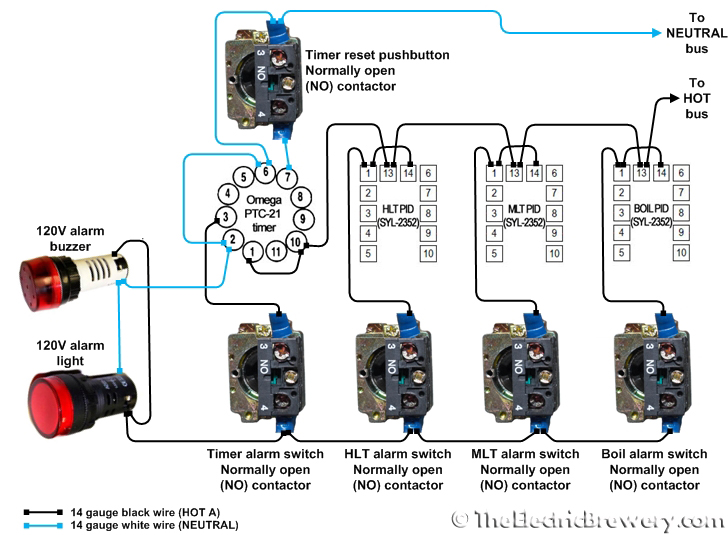

That's why I included a timer in my panel design too - for consistency. There are 4 different "things" (3 PIDs, 1 timer) that can sound the alarm all independently. My wiring diagram probably explains it best:

While each of the PID controller temperature alarm values is programmed separately, the PID alarm outputs (together with the timer alarm output) are wired in parallel. It only takes one of the 4 devices to sound the alarm.

If any of the PID controllers or the timer raises an alarm state, an internal relay in the device is closed allowing power to flow to the 120V alarm buzzer and 120V alarm light as long as the respective alarm selector switch is also in the ON position.

The 4 alarm on/off selector switches are used to enable/disable the individual device alarms as desired. When all 4 are off, the 120V alarm buzzer will not sound and the 120V alarm light will not turn on.

The timer terminals 6 (START) and 2 (NEUTRAL) are shorted and wired such that the timer starts counting down as soon as it is powered on.

So how are alarms used? Here's what I do - some temperature based, some time based:

- The hot liquor has reached strike temperature (alarm sent from the Hot Liquor Tank PID).

- The mash is complete (alarm sent from the countdown timer).

- The hot liquor has reached sparge temperature (alarm sent from the Hot Liquor Tank PID).

- The wort is about to boil (alarm sent from the Boil Kettle PID).

- The boil is complete (alarm sent from the countdown timer).

The timer's used to time various things such as mash time, boil time, etc.

As someone else already mentioned I like the Omega timer with four buttons for changing the time (instead of two). On the Omega PTC-21, you simply press any of the four buttons to change the four digits directly. On the Auber ASL-51 (or similar) you use one button to cycle through the digits and then a second button to change the value. Slower in use. But cheaper as was already mentioned.

If power to the control is interrupted during a countdown, the Omega PTC-21 remembers the time and continues where it left off when power returns. This is a very handy feature if you live in an area with frequent power interruptions or happen to turn the control panel off momentarily during use (either on purpose or by accident). The Auber ASL-51 timer does not have this non-volatile memory. When power is removed from the Auber timer and then re-applied, the countdown is reset.

Good luck!

Kal