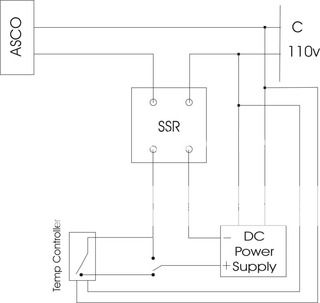

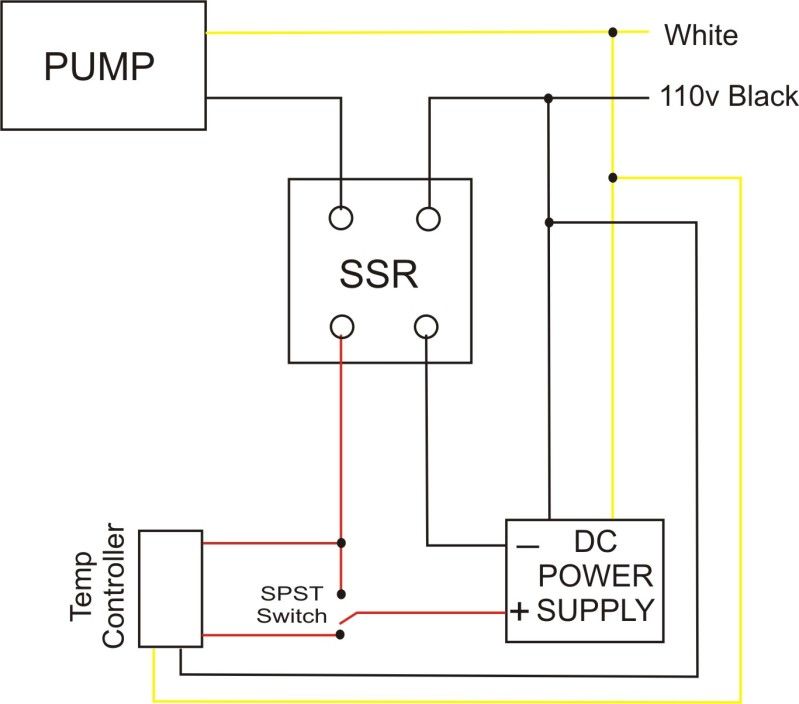

If you could write up exactly how you want the pump, heating element, and gas valve to behave when you flip the toggle switch to "on", I'm sure we can draw you up a wiring diagram. Also, list the operating voltages for the three devices. I'm fairly confident the pump is 110vac, but the control voltage for the SSR isn't obvious, and neither are the power and control for the gas valve.

Btw, forget the word "fuse" for now, because you're a long way from worrying about those. The word you probably want to keep in your head is "relay", because I'm pretty sure you're going to need one or two to make this work, and you may need a DC power supply as well...

Cheers!