paparker21

Well-Known Member

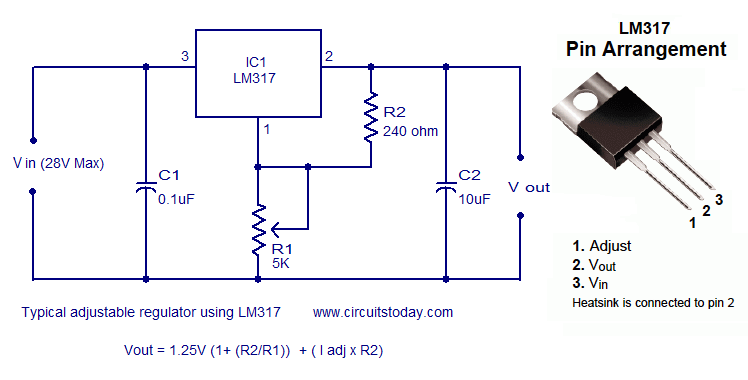

Okay, so i need some advice on my stir plate circuit. Following stirstarters.com i need the following:

2Kohm Potentiometer

330 ohm Resistor

LM317 Voltage regulator

.1 microfarad capacitor

so off i went to radioshack, home of astronomical prices and retail staff who are not at all required to know an electron from their ass. Found most of what i needed but have 2 questions:

1) a 5K pot was the closest i could find. What ill effects is this going to have? I assume that realistically, this will just lessen the chance of burning up the pot since I= V/R and since i've increased R and holding voltage constant, ill be reducing current.

2) they had .1 mfd caps in either polyester film or metal film style. How do i know which is more appropriate?

Thanks!

2Kohm Potentiometer

330 ohm Resistor

LM317 Voltage regulator

.1 microfarad capacitor

so off i went to radioshack, home of astronomical prices and retail staff who are not at all required to know an electron from their ass. Found most of what i needed but have 2 questions:

1) a 5K pot was the closest i could find. What ill effects is this going to have? I assume that realistically, this will just lessen the chance of burning up the pot since I= V/R and since i've increased R and holding voltage constant, ill be reducing current.

2) they had .1 mfd caps in either polyester film or metal film style. How do i know which is more appropriate?

Thanks!