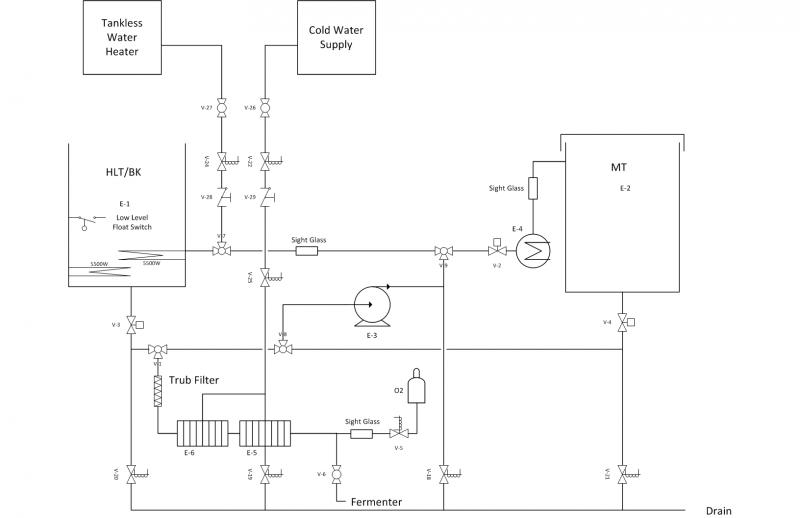

So I am building a new setup. It will be a 1 tier, 3 pot, 2 pump electric system. It is similar to theelectricbrewery.com but with a brewtroller for more automation so I don't have to move tubing around during the brewing process.

I could do this with a bunch of motorized 2 way valves or use a few less 3 way valves. Anyone have a strong opinion on which way to go? My main consideration will be setting this up so that it is easy to clean and drain after the brewing process. I HATE the cleaning part, so I'm trying factor that into the decision.

Nate

I could do this with a bunch of motorized 2 way valves or use a few less 3 way valves. Anyone have a strong opinion on which way to go? My main consideration will be setting this up so that it is easy to clean and drain after the brewing process. I HATE the cleaning part, so I'm trying factor that into the decision.

Nate