ClutchDude

Well-Known Member

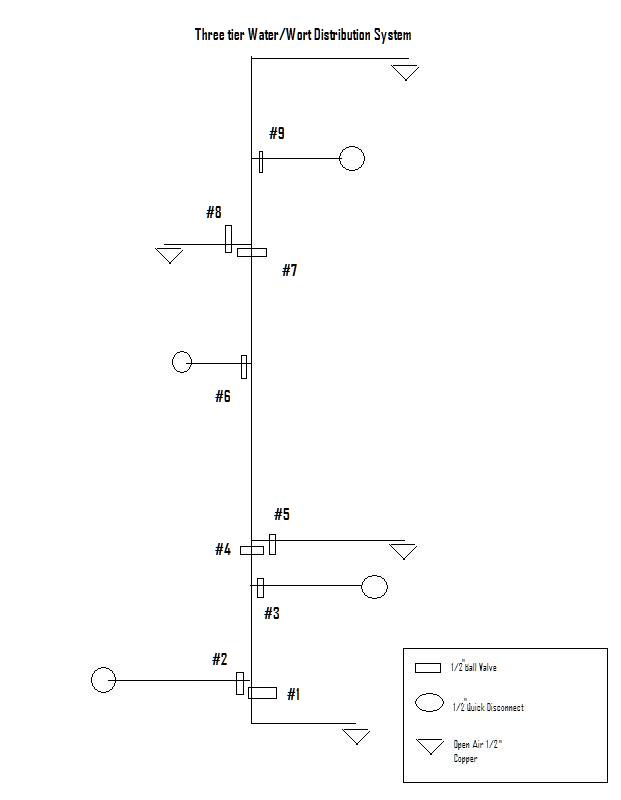

Anyone who uses a three tier brew rig knows the somewhat worried idea of having 7-8 gallons of scalding liquid in the air, with only lengthy hoses to distribute.

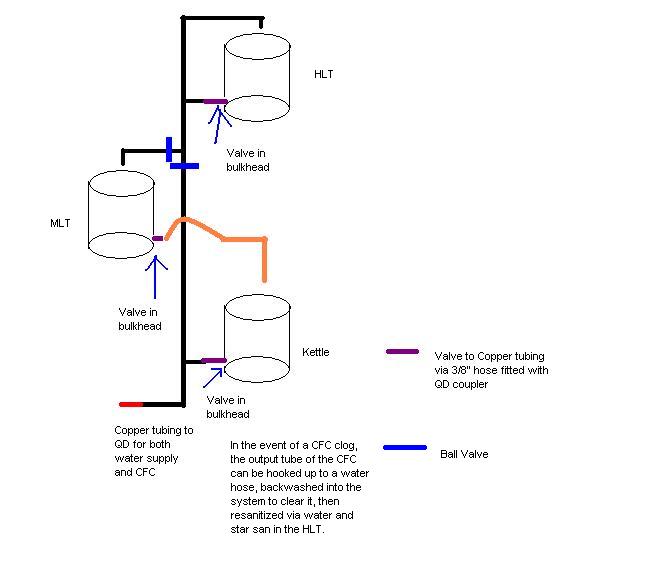

With the propane delivery already working fine, I'm thinking that high temperature hosing beverage hosing + quick disconnects + a bunch of ball valves + 20' of 1/2" copper tubing + ton of solder & flux = a good distribution system for your liquids.

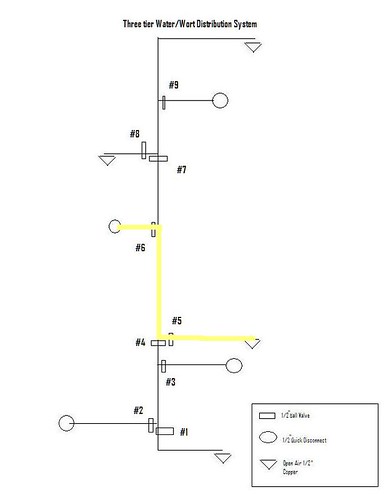

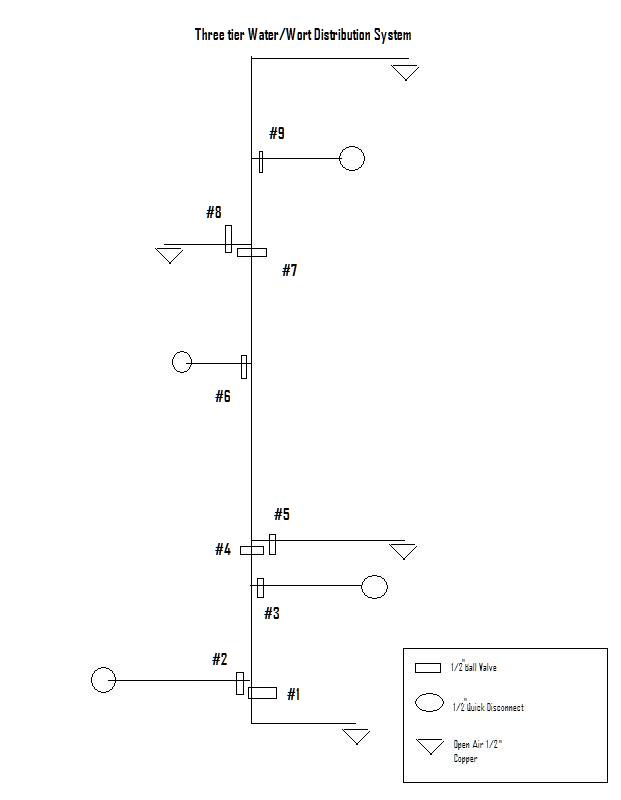

Below is a paintshop-tastic plan of the system. The black lines represent copper tubing. I'll try throwing together something more professional/user friendly tonight.

Here's the brew showplan:

Notes: A Keggle or Cooler will be under each triangle and it's ball valve hooked to the QD. To connect this to the QD, a high-temp beverage hose with proper fittings are used. I'm 99% sure I don't need a vents but someone may point out I need them.

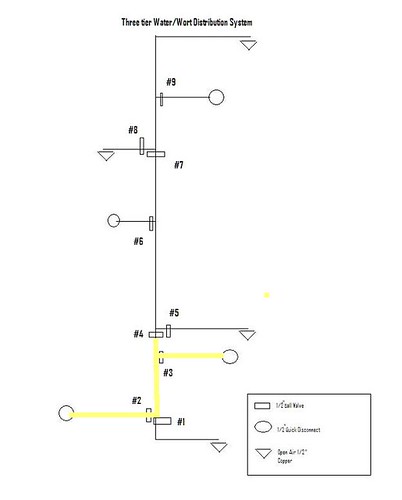

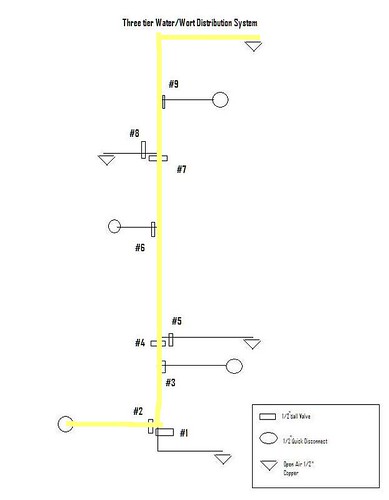

1. Attach water source (Filtered hose water) to bottom QD.

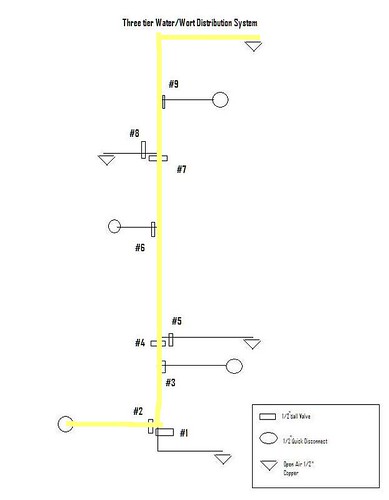

2. Filling the HLT- All valves but #2, #4 and # 7 are closed, water is forced to the very top. Fill HLT with needed water.

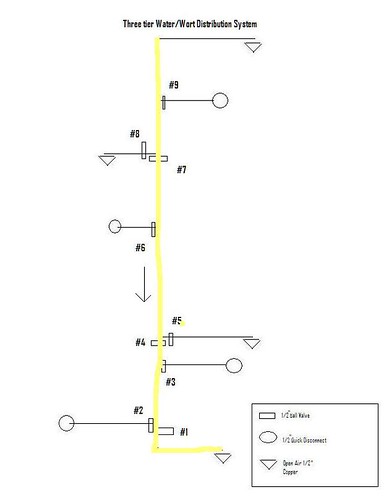

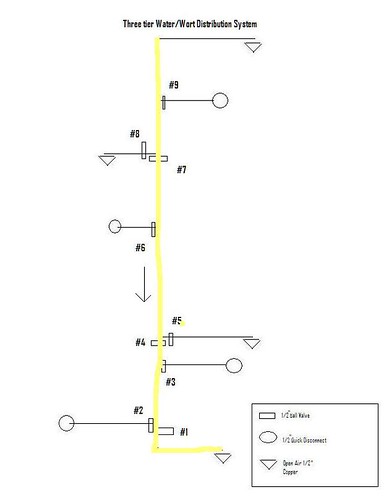

3. Disconnect water source. Open Valve #1 to drain any water in the system. Heat HLT to needed temp.

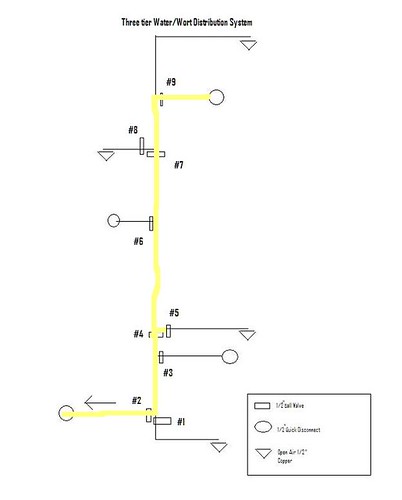

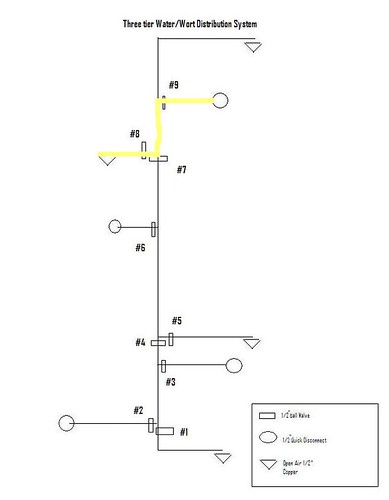

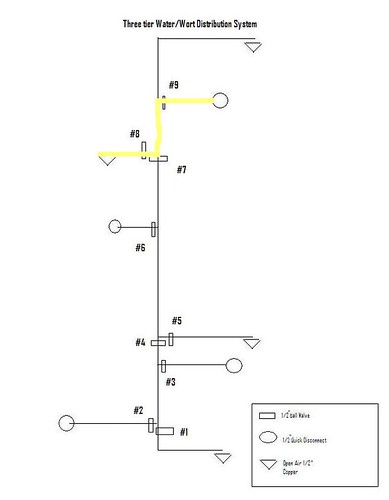

4. HLT hits needed temperature. Close #1, #2,#4, #7. Open HLT, #8, #9 to prewarm mash tun then mash grains. Close HLT when done.

EDIT: Add phots, so splitting post.

With the propane delivery already working fine, I'm thinking that high temperature hosing beverage hosing + quick disconnects + a bunch of ball valves + 20' of 1/2" copper tubing + ton of solder & flux = a good distribution system for your liquids.

Below is a paintshop-tastic plan of the system. The black lines represent copper tubing. I'll try throwing together something more professional/user friendly tonight.

Here's the brew showplan:

Notes: A Keggle or Cooler will be under each triangle and it's ball valve hooked to the QD. To connect this to the QD, a high-temp beverage hose with proper fittings are used. I'm 99% sure I don't need a vents but someone may point out I need them.

1. Attach water source (Filtered hose water) to bottom QD.

2. Filling the HLT- All valves but #2, #4 and # 7 are closed, water is forced to the very top. Fill HLT with needed water.

3. Disconnect water source. Open Valve #1 to drain any water in the system. Heat HLT to needed temp.

4. HLT hits needed temperature. Close #1, #2,#4, #7. Open HLT, #8, #9 to prewarm mash tun then mash grains. Close HLT when done.

EDIT: Add phots, so splitting post.