You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

how do I get nice blue SS welds, not oxidized ?

- Thread starter brewman !

- Start date

Help Support Homebrew Talk - Beer, Wine, Mead, & Cider Brewing Discussion Forum:

This site may earn a commission from merchant affiliate

links, including eBay, Amazon, and others.

Not an expert here, but use less heat (or travel faster) and increase your argon coverage. Also make sure you're not melting through to the back side of the weld (if it's unshielded), which can also pull contaminants through to the front.

- Joined

- Jun 2, 2011

- Messages

- 3,834

- Reaction score

- 364

Back gas with argon.

sr20steve

Well-Known Member

Grey means too much heat input. If your welding thin SS, make sure your purge the backside of weld with argon, or use solar flux B to prevent sugaring of the weld. Using a gas lens and as big of a cup as you can get, and small diameter tungsten also really helps with thin stuff. I like to use 1/16" tungsten and filler. Also check your hoses for leaks as well because that can cause contamination. A good way to check if to strike a arc on a piece of SS in just one spot and let off the pedal keeping the torch directly over the spot untill the gas stops, the spot should be silver or a bit gold or you have a leak.

sr20steve

Well-Known Member

Also, there are few ways to control heat input I figure I will mention. Heat input is not always the problem of too much amps, it can also be from traveling to slow as well. It's normally better to use a higher amps and faster travel speed to achieve a weld with less heat. You can also use things like copper on the back of a weld to try and suck some of the heat out of the weld (if the joint will allow it).

If your welder can pulse it can help with to much heat

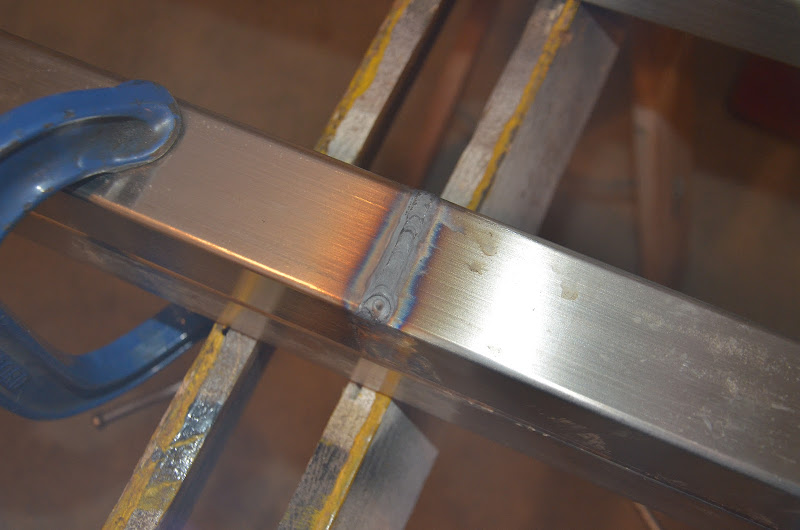

Its not a problem of purging the back side because its happening even on thicker material. Here is a picture of a bead laid on 1/4" SS. There is no way it was penetrating through on that.

I don't think its a heat problem. On 0.100 wall SS, I am waiting for the puddle and waiting to add rod. Maybe I need to turn up the heat and move faster ?

I think it must be the nozzle on the torch. I'm using a #5 cup. Maybe I need a gas lens ?

I don't think its a heat problem. On 0.100 wall SS, I am waiting for the puddle and waiting to add rod. Maybe I need to turn up the heat and move faster ?

I think it must be the nozzle on the torch. I'm using a #5 cup. Maybe I need a gas lens ?

Grey means too much heat input. If your welding thin SS, make sure your purge the backside of weld with argon, or use solar flux B to prevent sugaring of the weld. Using a gas lens and as big of a cup as you can get, and small diameter tungsten also really helps with thin stuff. I like to use 1/16" tungsten and filler. Also check your hoses for leaks as well because that can cause contamination. A good way to check if to strike a arc on a piece of SS in just one spot and let off the pedal keeping the torch directly over the spot untill the gas stops, the spot should be silver or a bit gold or you have a leak.

Some good ideas here. Thanks.

I'm using a 1/16" electrode on the tubing. I'm probably going to step up to 3/32" to get a bit wider arc. Its focused too small with the 1/16" electrode.

I'd use a bigger cup (#8?) and turn up the argon flow a bit.

sr20steve

Well-Known Member

Stick with a 1/16 tungsten unless your welding thicker material that requires more amps. It takes less amps with a 1/16 electrode to accomplish the same weld than a 3/32nd so basically less heat input.

If your not using a gas lens that may be your problem, you must use a gas lens and crank up the flow to 20+. I like to use a large gas lens with a 12 cup on a 17/18 series torch, and a large gas lens and a 8 for a 9/20 series torch. A gas lens will allow more stick out as well for tight spots.

Post some pics of your progress!

If your not using a gas lens that may be your problem, you must use a gas lens and crank up the flow to 20+. I like to use a large gas lens with a 12 cup on a 17/18 series torch, and a large gas lens and a 8 for a 9/20 series torch. A gas lens will allow more stick out as well for tight spots.

Post some pics of your progress!

Stick with a 1/16 tungsten unless your welding thicker material that requires more amps. It takes less amps with a 1/16 electrode to accomplish the same weld than a 3/32nd so basically less heat input.

If your not using a gas lens that may be your problem, you must use a gas lens and crank up the flow to 20+. I like to use a large gas lens with a 12 cup on a 17/18 series torch, and a large gas lens and a 8 for a 9/20 series torch. A gas lens will allow more stick out as well for tight spots.

OK, I'll get some larger cups and lenses and see what happens.

On the welds or on the brewstand ? I'll do the former in this thread.Post some pics of your progress!

The stand build is here, in case anyone missed it.

https://www.homebrewtalk.com/f51/birth-zeus-non-typical-brewstand-build-368010/

sr20steve

Well-Known Member

I'd be willing to be a large gas lens will fix your woes, your beads look like you grasp TIG just fine. I use a gas lens on everything, so don't think that it's just for SS. You are using 100% argon correct?

I'd be willing to be a large gas lens will fix your woes, your beads look like you grasp TIG just fine. I use a gas lens on everything, so don't think that it's just for SS. You are using 100% argon correct?

Yep.

FWIW, I wanted a wider arc so that I don't have to weave the torch as much to get puddling on both sides of the pieces I'm welding. I'll try a few beads with a 3/32" electrode and report back.

I don't think I'm getting much heat into my work at all. And if I had a bigger puddle, I could certainly move faster or add pulse to keep the heat down.

sr20steve

Well-Known Member

Weaving allot of times will actually help the appearance of a stainless weld (with the right heat of course) because as you weave from side to side the other side cools while still under gas coverage. Here's a experiment you can do as well if your not happy with the appearance of a weld, hit it with a clean SS wire wheel, then turn down the amps and just do a dry wash side to side (no filler) moving pretty quickly over the bead and you'll be amazed at the beautiful golden weld you'll leave behind, now this is kinda cheating but I do it all the time, lol.

But try the 3/32 and see how it goes, doesn't hurt to try. The faster you travel with good gas coverage the better. This thin stuff is a pita.

But try the 3/32 and see how it goes, doesn't hurt to try. The faster you travel with good gas coverage the better. This thin stuff is a pita.

Weaving allot of times will actually help the appearance of a stainless weld (with the right heat of course) because as you weave from side to side the other side cools while still under gas coverage. Here's a experiment you can do as well if your not happy with the appearance of a weld, hit it with a clean SS wire wheel, then turn down the amps and just do a dry wash side to side (no filler) moving pretty quickly over the bead and you'll be amazed at the beautiful golden weld you'll leave behind, now this is kinda cheating but I do it all the time, lol.

I don't think TIG welding with the parent materials is cheating. I think its frigging cool !

OK.But try the 3/32 and see how it goes, doesn't hurt to try. The faster you travel with good gas coverage the better.

Coming from trying to do it with a stick machine, its effortless with TIG.This thin stuff is a pita.

Similar threads

- Replies

- 13

- Views

- 852

- Replies

- 32

- Views

- 2K

- Replies

- 2

- Views

- 945

- Replies

- 18

- Views

- 2K