2funkids

Active Member

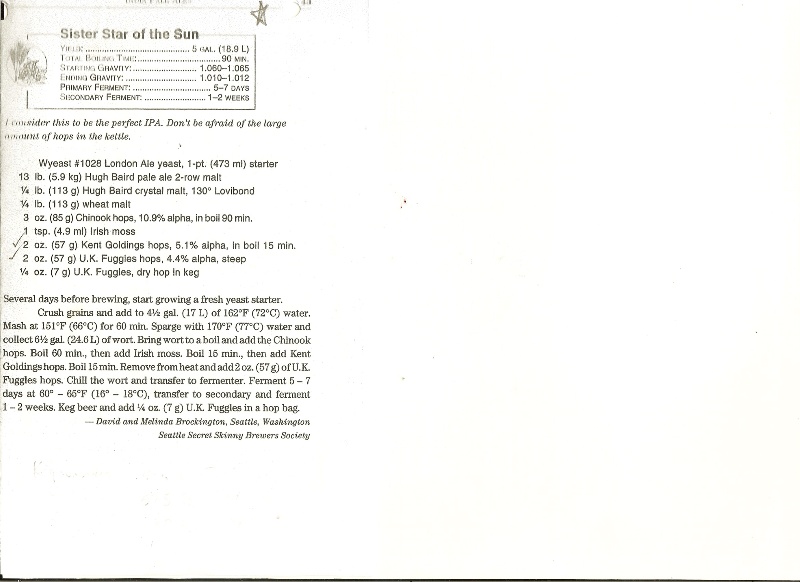

Hi Guys, I am slowly learning this water thing...Using this recipe the SRM is about 8.8. After looking at Palmer's Nomograph and the EZ watercalcualtor I came up with these numbers. I am building up from RO water, All grain. 4.5 gallons in mash and 3G for the sparge/boil addition.

Ca 235

Mg 16

Na 55

Cl 149

So4 200

CaCo3 214

Alkalinity 37

Chloride to Sulfate ratio .75

Am I way off or does this look pretty good? If you have a different recommendation can you provide the Nomograph numbers and/or the EZ water numbers to help me and other learn the why what is recommended is better. It looks like this recipe counts on some of the maltiness to balance the hops so I think the Chloride to sulfate shouldn't be Very bitter??

Also, can someone help me understand the the calcium amounts throughout the process....I am reading that I want 100ppm in the boil. I am also reading that the grain should produce 35ppm in a 1.040 wort and that 50% of the calcuim will be lost to the grain and some may be lost due to precipitation with bicarbonates?? Using what ever profile I end up with after i get the recommendations, could someone show me the the projected calcium in boil and how it came to that.??? Something like this:

End up with 100ppm in boil

50% lost to spent grain = 200

some loss to precip with bicarbonates..I don't understand if i need to understand this.

.

.

Ca from additions 235+35

Ca from Grain 35

I have more questions, but I want to wait until I understand more up to this point.

Ca 235

Mg 16

Na 55

Cl 149

So4 200

CaCo3 214

Alkalinity 37

Chloride to Sulfate ratio .75

Am I way off or does this look pretty good? If you have a different recommendation can you provide the Nomograph numbers and/or the EZ water numbers to help me and other learn the why what is recommended is better. It looks like this recipe counts on some of the maltiness to balance the hops so I think the Chloride to sulfate shouldn't be Very bitter??

Also, can someone help me understand the the calcium amounts throughout the process....I am reading that I want 100ppm in the boil. I am also reading that the grain should produce 35ppm in a 1.040 wort and that 50% of the calcuim will be lost to the grain and some may be lost due to precipitation with bicarbonates?? Using what ever profile I end up with after i get the recommendations, could someone show me the the projected calcium in boil and how it came to that.??? Something like this:

End up with 100ppm in boil

50% lost to spent grain = 200

some loss to precip with bicarbonates..I don't understand if i need to understand this.

.

.

Ca from additions 235+35

Ca from Grain 35

I have more questions, but I want to wait until I understand more up to this point.