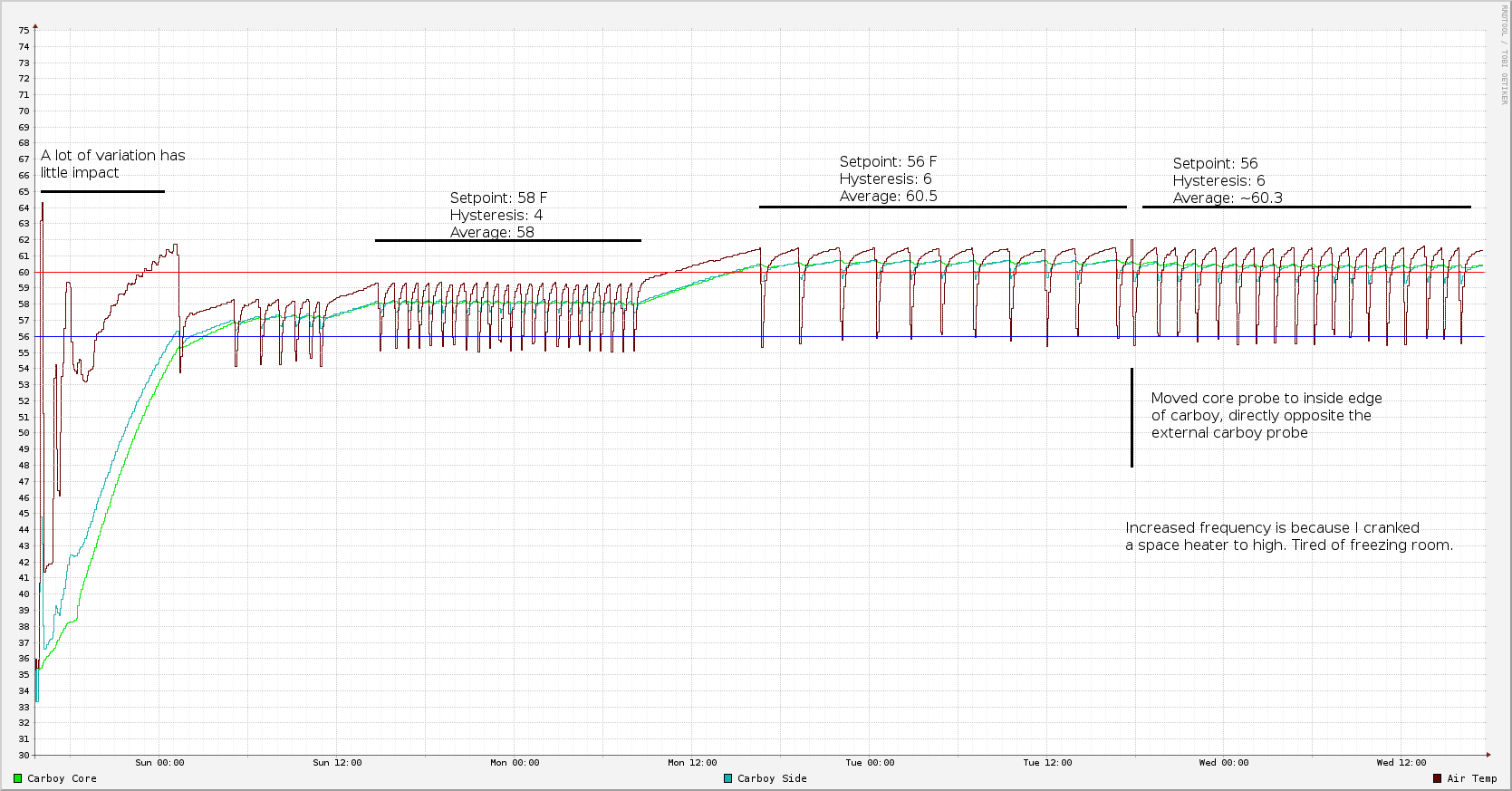

Fermentation is known to produce heat and the actual temperature of the fermenting wort is therefore higher than its surroundings. I have a thermometer in my fermenting fridge but I can't help but wonder how reliable is the reading I get. I don't have a thermometer in the fermenter or wort itself.

Did anyone experiment with taking temperature of the fermenting wort vis-a-vis its surroundings?

Did anyone experiment with taking temperature of the fermenting wort vis-a-vis its surroundings?