Swagman

Well-Known Member

Had a brewer come over a while back for some Tig welding on kegs. He also had one of the rubber kegs that he didn't want so he left here in the shed.

It's been setting here for a few months so the other day I sit it up on the bench to see what could be done with one.

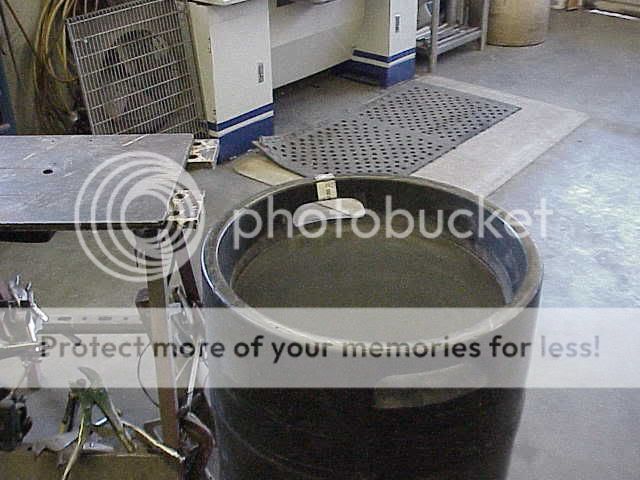

I took my router and made a few pass around the top until I was thru the rubber. I found there is also a plate that secures around the neck I would guess for strength. After removing the rubber and the plate I plasma cut the rest of the top out. This is where I found the thickness of stainless steel used to form the keg is a lot thinner a little more than a 1/32. The outside showed no damage to speak off but the inside showed every blow or drop that had happen to it. A length of oak handle and a hammer it looked a little better.

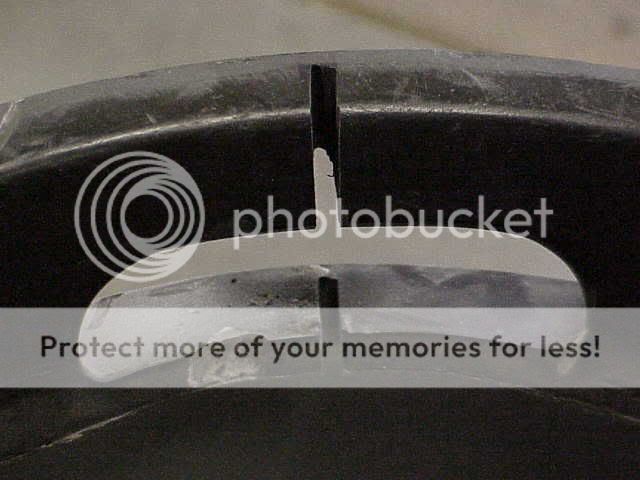

I used a 3 1/2 hole saw to cut part way thru the rubber and finished with a box knife.If your not careful you will go straight thru the stainless. Then drilled a 1 inch hole for the coupler. I welded two couplers in for valve and pick up tube and one for a thermometer.

I plan to add a false bottom that will run about 15 inchs in diameter. I will cut to slits one on each side for the false bottom pass into the keg.

I guess it will made a good mash tun for some brewer at least its insulated well lol. But I think I will pass on the next one that comes along.

God Bless

Dominus Vobiscum

Swagman

It's been setting here for a few months so the other day I sit it up on the bench to see what could be done with one.

I took my router and made a few pass around the top until I was thru the rubber. I found there is also a plate that secures around the neck I would guess for strength. After removing the rubber and the plate I plasma cut the rest of the top out. This is where I found the thickness of stainless steel used to form the keg is a lot thinner a little more than a 1/32. The outside showed no damage to speak off but the inside showed every blow or drop that had happen to it. A length of oak handle and a hammer it looked a little better.

I used a 3 1/2 hole saw to cut part way thru the rubber and finished with a box knife.If your not careful you will go straight thru the stainless. Then drilled a 1 inch hole for the coupler. I welded two couplers in for valve and pick up tube and one for a thermometer.

I plan to add a false bottom that will run about 15 inchs in diameter. I will cut to slits one on each side for the false bottom pass into the keg.

I guess it will made a good mash tun for some brewer at least its insulated well lol. But I think I will pass on the next one that comes along.

God Bless

Dominus Vobiscum

Swagman