Here is a look at what I have been doing for the last month or so. I committed to building an electric sculpture modeled after some of the systems I have seen here on the board. I have been gathering ideas.

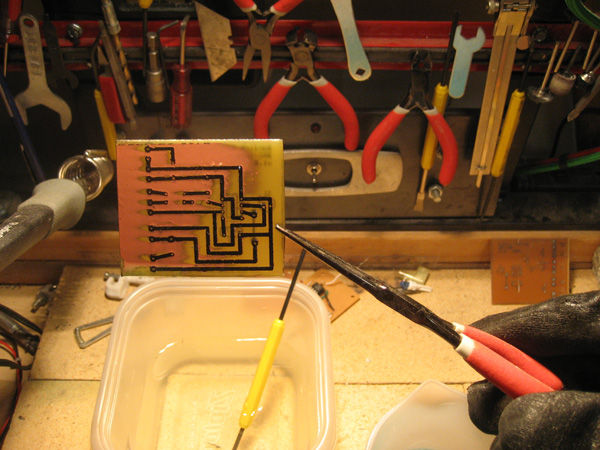

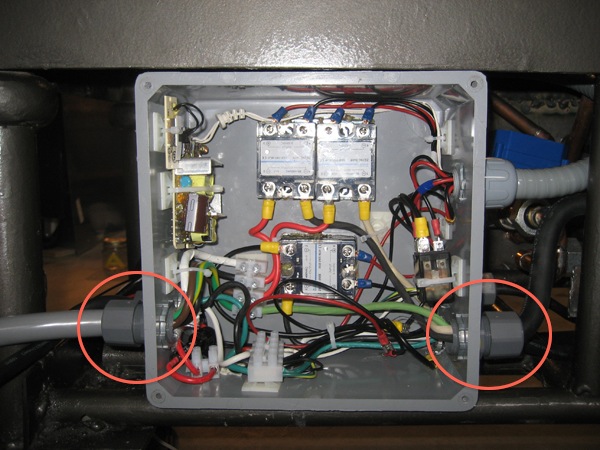

I am using three vessels. 2 sanke kegs, 1 for the boil kettle and the other for the mash tun. I have a corny keg that will be used as an hlt/heat transfer tank. The HLT will be powered with a 1500w element and controlled by a PID. The BK will have a 5500w element and a PWM circuit to control the temp.

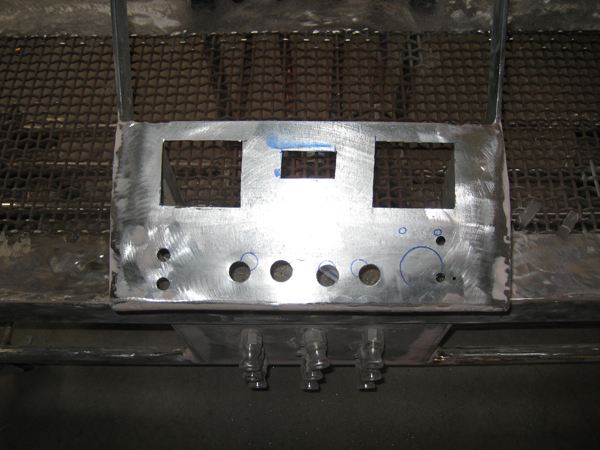

There will be two digital oven thermometers mounted into the panel to give readouts from the boil kettle and the mash tun.

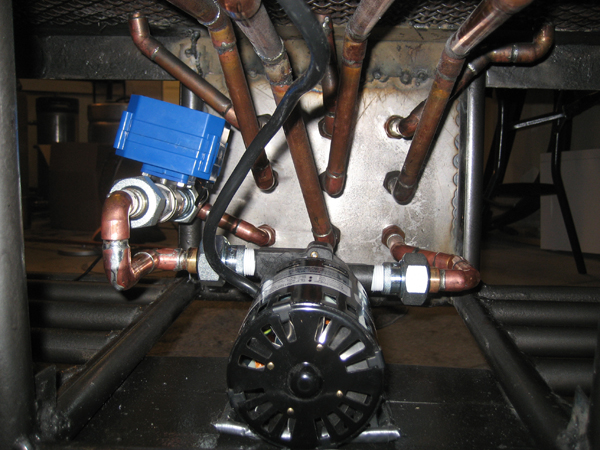

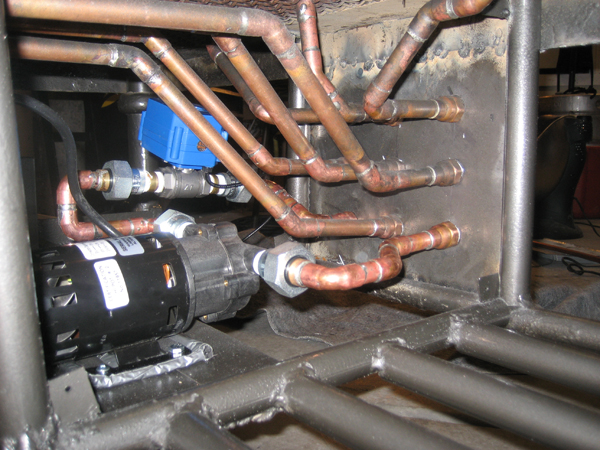

There will be a quick change panel on the front of the stand to select the route the pump takes. This will be accomplished with several short "jumper" tubes. All connections to the kegs will be quick release so the pots can be cleaned easier. I am also planning some sort of faucet with a quick release for a garden hose.

Here are the pics. I will try and get pictures up when there is something to see. You will notice I like to use scraps from the habitat store.

The Stand:

I am using three vessels. 2 sanke kegs, 1 for the boil kettle and the other for the mash tun. I have a corny keg that will be used as an hlt/heat transfer tank. The HLT will be powered with a 1500w element and controlled by a PID. The BK will have a 5500w element and a PWM circuit to control the temp.

There will be two digital oven thermometers mounted into the panel to give readouts from the boil kettle and the mash tun.

There will be a quick change panel on the front of the stand to select the route the pump takes. This will be accomplished with several short "jumper" tubes. All connections to the kegs will be quick release so the pots can be cleaned easier. I am also planning some sort of faucet with a quick release for a garden hose.

Here are the pics. I will try and get pictures up when there is something to see. You will notice I like to use scraps from the habitat store.

The Stand: