This thread will contain a description of the worst brew day I have ever had... I just need to get through the brew session in one piece first....

-walker

-walker

Walker-san said:This thread will contain a description of the worst brew day I have ever had... I just need to get through the brew session in one piece first....

-walker

Walker-san said:This thread will contain a description of the worst brew day I have ever had... I just need to get through the brew session in one piece first....

-walker

Ize said:My spidey senses are telling me it involves physical damage, AND crappy efficiency.

Ize

Reverend JC said:I should have warned you yesterday that this weekend may be a bad brew weekend.

Reverend JC said:I should have warned you yesterday that this weekend may be a bad brew weekend.

cweston said:Hmm... maybe there's something to that. I brewed Friday--had more tropuble than I've ever had hitting my mash temps, had terrible efficiency.

I have two propane tanks--I always fill one as soon as I empty it. So that's at least one thing I don't have to worry about going wrong.

Walker-san said:Missed the OG by 9 points, and there are a lot of grain particles in the brew.

This is going to be teriibly astringent. I doubt it ever makes it into a keg.

I'll taste when it's ready to rack to secondary. If it's as astringent as I think it is going to be, this is going right down the drain.

-walker

Schlenkerla said:That's no joke. I always argue with SWMBO about having a 2nd tank handy. She always claims there is no need to have two.....

the_bird said:OG was a little low, eh, who cares?

BierMuncher said:I could have had a disaster if it weren't for the Beer Gods smiling on me. I dropped this full MF'r trying to lift it to this bench. My right hand around the neck, left hand underneath. Done it dozens of times.

My left had must have been a bit wet cuz just as I got it right to the edge, I bumped the shelf, the neck slipped out of my hand, the weight of the carboy fell against me and knocked me on my butt...bounced off my leg and hit the floor from about 6 inches. I saw an entire weekend of mopping up wort and picking broken glass out of my ass flashing before my eyes.

Thank the beer Gods I followed my own rule and placed a piece of carpet underneath the area first.

This carboy bounced, sloshed, spit wort in my face, wobbled like a weeble and came to rest...upright.

Aside from a lifetime of adrenalin pushing my heart rate to about 180...no harm done.

Walker_San...sorry bout your misfortunes.

View attachment 1244

Yeah, I expect to notice it. The IBUs will mask it somewhat, but astringency lingers long on the tounge and is not pleasant at all.Schlenkerla said:Will you notice high astrigency with high IBU's? The two on deck look high...

Schlenkerla said:Walker-San I'd splurge for the extra deposit have at least two (LPG tanks) on hand all the time.

the_bird said:Brainstorming here....

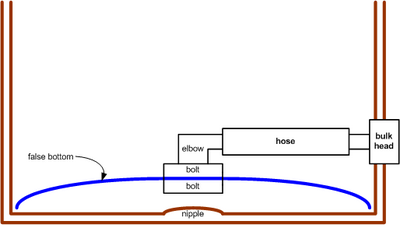

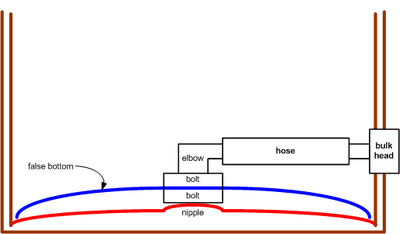

What if you got a piece of round C-PVC, maybe three inches or so in diameter, maybe an inch high. Cut a crapload of holes in it, just leave enough structure to keep it intact so that it can support the weight of the grain. Place that around the nipple in the center of the mash tun and set the false bottom on top. This will support the center false bottom, keep it from compacting all the way down to the nipple. The holes will allow the sweet wort to flow into the center of the tun to the inlet. Need a lot of holes so that this flow doesn't get restricted and you lose the suction.

I don't know if that would work, but if it does, it's a fifty-cent solution.

Does that make sense?

Willsellout said:I don't even think you have to drill a bunch of holes...maybe just a few because the false bottom will strain for you right?

the_bird said:Brainstorming here....

What if you got a piece of round C-PVC, maybe three inches or so in diameter, maybe an inch high. Cut a crapload of holes in it, just leave enough structure to keep it intact so that it can support the weight of the grain. Place that around the nipple in the center of the mash tun and set the false bottom on top. This will support the center false bottom, keep it from compacting all the way down to the nipple. The holes will allow the sweet wort to flow into the center of the tun to the inlet. Need a lot of holes so that this flow doesn't get restricted and you lose the suction.

I don't know if that would work, but if it does, it's a fifty-cent solution.

Does that make sense?

the_bird said:Brainstorming here....

What if you got a piece of round C-PVC, maybe three inches or so in diameter, maybe an inch high. Cut a crapload of holes in it, just leave enough structure to keep it intact so that it can support the weight of the grain. Place that around the nipple in the center of the mash tun and set the false bottom on top. This will support the center of the false bottom, keep it from compacting all the way down to the nipple. The holes will allow the sweet wort to flow into the center of the tun to the inlet. Need a lot of holes so that this flow doesn't get restricted and you lose the suction.

I don't know if that would work, but if it does, it's a fifty-cent solution.

Does that make sense?

Enter your email address to join: