Hello to all of you!

I have dilemma on how to connect and wire two heating elements and one PID, I hope someone will help me out with this.

This is my setup:

Auberins SYL-2352

2 SSRs 25A

2 Heat sinks

2 2000w 220V heating elements (both in HLT)

I will use two heating elements (2 x 2000w) in my HLT, and I would like to be able to turn on both of them or only one to heat and maintain water temperature.

They will both work at the start, when water temperature is reached PID will turn off both of them and I will turn off one of them (with switch) and let the other one to maintain temperature.

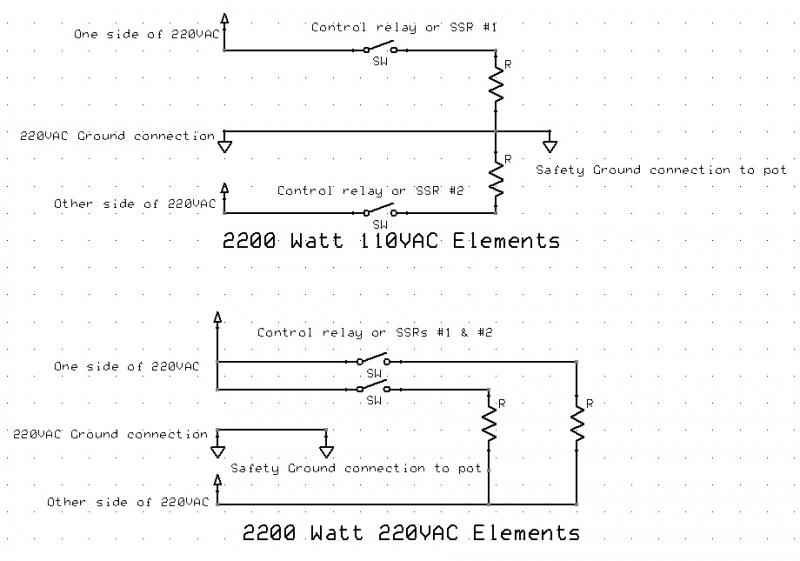

I searched through forum and I found that they have to be wired in parallel, can I use one of these wiring diagrams (and which one) to wire it:

https://www.homebrewtalk.com/f51/electric-brewing-question-167052/#post1931368

https://www.homebrewtalk.com/f170/my-two-5500-watt-element-1-pid-ssr-build-281085/#post3485613

What dou you think about this idea, can it be done or maybe it is wiser to connect both heating elements so they run as single one (if I run them as single one do I need two SSRs)?

I have dilemma on how to connect and wire two heating elements and one PID, I hope someone will help me out with this.

This is my setup:

Auberins SYL-2352

2 SSRs 25A

2 Heat sinks

2 2000w 220V heating elements (both in HLT)

I will use two heating elements (2 x 2000w) in my HLT, and I would like to be able to turn on both of them or only one to heat and maintain water temperature.

They will both work at the start, when water temperature is reached PID will turn off both of them and I will turn off one of them (with switch) and let the other one to maintain temperature.

I searched through forum and I found that they have to be wired in parallel, can I use one of these wiring diagrams (and which one) to wire it:

https://www.homebrewtalk.com/f51/electric-brewing-question-167052/#post1931368

https://www.homebrewtalk.com/f170/my-two-5500-watt-element-1-pid-ssr-build-281085/#post3485613

What dou you think about this idea, can it be done or maybe it is wiser to connect both heating elements so they run as single one (if I run them as single one do I need two SSRs)?