BrewMoreBeers

Well-Known Member

Kal and P-J:

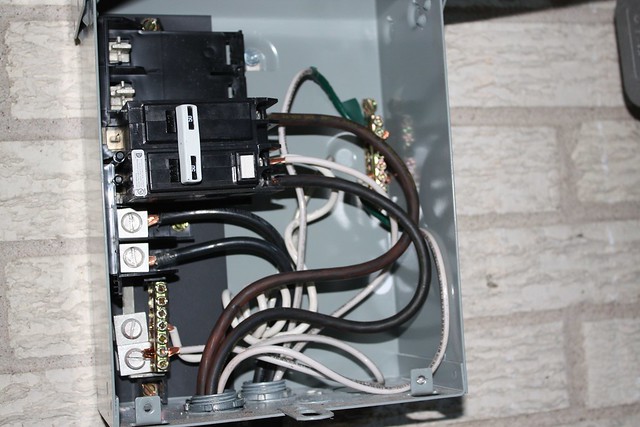

Thanks for setting me straight. I forgot that there is no ground/neutral on the elements - only hot1 and hot2. It now makes sense that the element only fires when hot1 and hot2 are both live to complete the circuit.

Thanks for setting me straight. I forgot that there is no ground/neutral on the elements - only hot1 and hot2. It now makes sense that the element only fires when hot1 and hot2 are both live to complete the circuit.