67cougargt

Well-Known Member

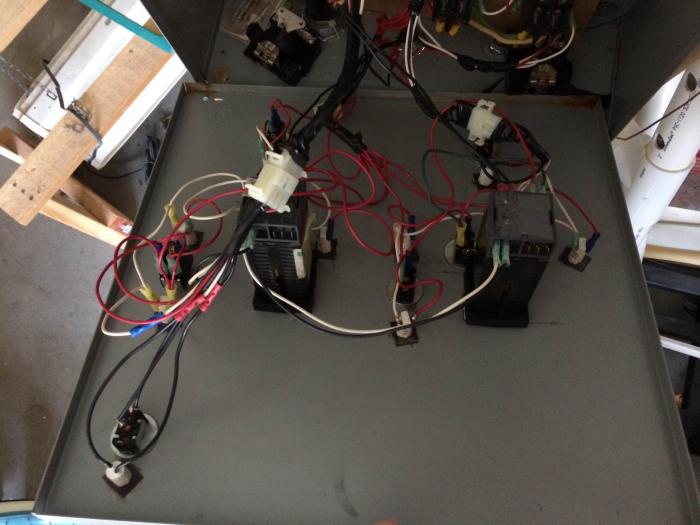

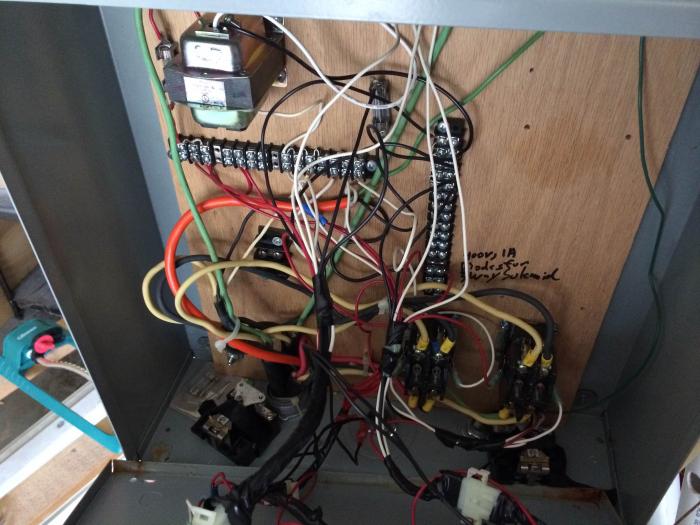

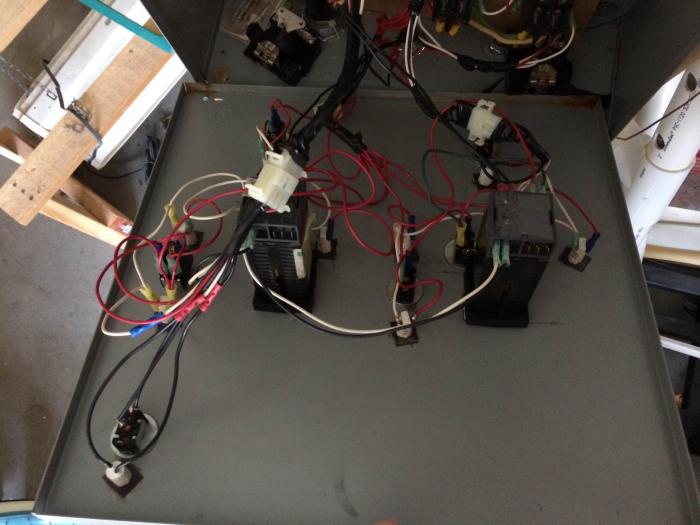

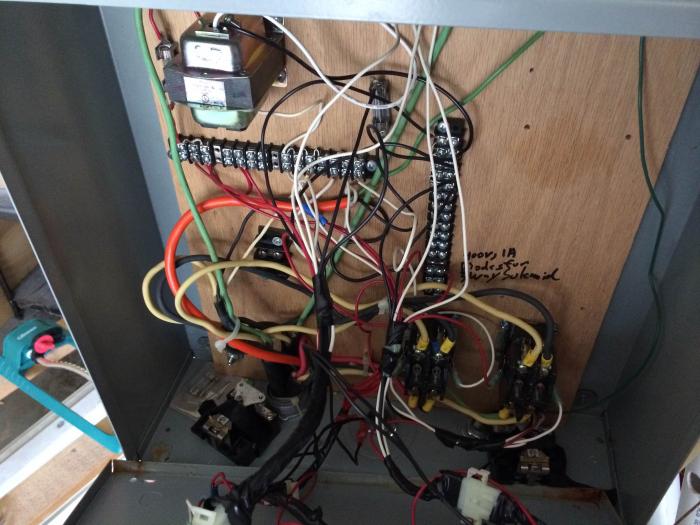

I am looking for help taking an electric brewery I purchased from someone else and rewiring it to be safe and to make the best use of the parts already in use. Because it already has two elements in the hot liquor tank, (4500 and 5500 watts) I would like to utilize them for the quick heating time. The previous owner used gas for boiling independent of this panel. I would like to go all electric and convert one of my keggles to electric for boiling. I think this diagram by PJ, less the extra element in the boil kettle is what I would like to do. I have purchased a 60 Amp GFCI breaker switch and 6-3 wire with ground to run to the control panel. I would like the ability to run all three elements at once to do back to back brewing. Looking at the panel switches and PIDs(CAL 9900s) I already have, I think I need to add din mounted breakers and SSRs and wire an emergency stop. I would appreciate any input into best utilizing the components I have and making the system safe. Thanks!