gunner65

Well-Known Member

If you ever wondered if nylon voile will withstand touching the element during the boil it will.

My setup is a 5500W ULWD element. Last night I was cleaning my setup in prep for a brew day today. I have heard some people burning the bag on the element and I have heard others say they don't.

I took a scrap piece of the voile I had and tied it around the element snugly. Let the water come to a rolling boil for ten minutes then shut it down. Pulled the material out not a mark on it.

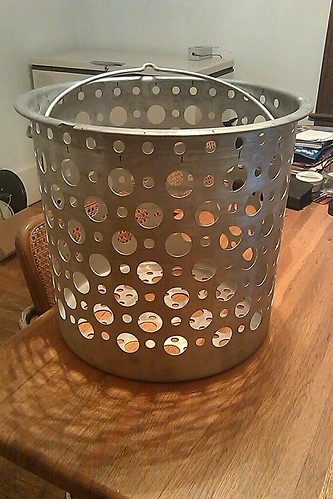

Now that stainless cage I built to keep the bag off the element seems like a waist of my time and efforts. I fretted over how to cover the element for some time before coming up with my design. I think it takes up too much space so I am glad that my experiment worked out.

My setup is a 5500W ULWD element. Last night I was cleaning my setup in prep for a brew day today. I have heard some people burning the bag on the element and I have heard others say they don't.

I took a scrap piece of the voile I had and tied it around the element snugly. Let the water come to a rolling boil for ten minutes then shut it down. Pulled the material out not a mark on it.

Now that stainless cage I built to keep the bag off the element seems like a waist of my time and efforts. I fretted over how to cover the element for some time before coming up with my design. I think it takes up too much space so I am glad that my experiment worked out.