shroomzofdoom

Well-Known Member

As the title says I am going to be starting a BCS build. For the impatient, this is probably going to take a while. I’ll post on occasion as I build/buy things or make improvements but I expect this project to take up to a year. My schedule has me finishing this summer but I am slated to have a few surgeries this year which could slow me down.

I’ve yet to decide on RIMS or HERMS….I know, I know…but I’ve been fully committed to doing each at one point or another. They both appeal to me—I don’t want to turn this into a RIMS vs. HERMS thread but the truth is I could be swayed either way. I was literally set to pop on the Brewer’s Hardware RIMS until this weekend. Watching my club’s low tech use of HERMS to hold mash temp on a 90-100gal mash convinced me that this is a very basic process.

I’ll probably have to decide in a few weeks. If I go RIMS, I am using the Brewer’s Hardware product; if HERMS it would likely be one that is not hard plumbed, over side if the keg and removable.

So…what’s the general project goals?

-Be able to handle 5-10 gallon batches

-Three 15.5 gallon Sanke vessels--2 untouched, one in use today

-Be able to fly sparge

-All weldless

-Keggles have to be removed from the setup for storage. (semi-permanent)

-Bottom drains on the MLT and BK. The HLT already has a diptube. I made a great 2x2000w/110v boil kettle a few months ago to get off the stovetop.

Will probably convert this to 220w and plug the other hole

-I turned my old immersion chiller into a CFC and will use that to chill until I have the funds for a plate chiller.

My house is fed by a 100amp main panel in the basement with a 60amp subpanel upstairs

Main Panel (basement)

Sub panel (upstairs)

Not sure why they had two panels (house is small) but there are lots of spaces in the main panel. There’s not a 220 circuit in the house. I hope I am not heading to an overload situation but my plan is to drop a 50W spa panel right off the main panel and manually limit my amperage draw elsewhere in the house. I think it should fairly easy not to run high amperage while brewing. Being an early riser, I usually start brewing before daylight and finish by Noon. We plan on upgrading to 200 amp service with central air, but not for a while.

The panel is about 30 feet away from my brewing area. On brew day, pretty sure I will have to run an RV cord to the control panel. Basement is completely finished—no permanent installation will permit a finished setup without a high degree of wall cutting or conduit.

I grabbed this cart at Costco for around $129, I can use this for a two vessels or deploy it elsewhere.

I may hang the HLT on the wall with removable brackets. Still not 100% sure. Space is at a premium, so I would like the ability to remove all the keggles to my furnace room for storage when we have parties. Using the cart probably meets chopping a few inches off the legs and punching two 1” holes through the surface for the bottom drains. If done right, there is no reason these holes can’t be covered/capped and the table mostly repurposed for use during parties.

The game plan:

Move router, fish 50 ft of RJ45-DONE

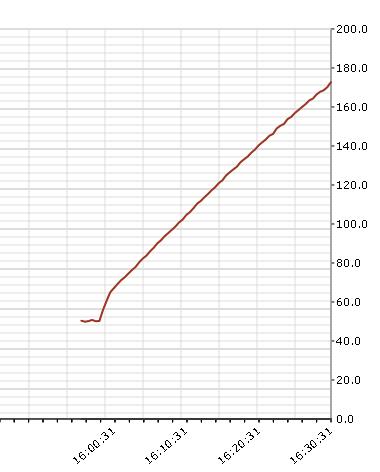

Replace analog probes with sensors and run first brew with BCS monitoring/logging via iPhone-DONE

Cut kegs and plumb bottom drains/valves (ordered parts) (late Feb)

Rig up Spa Panel and build a 220v outlet into it. (late Feb)

Rough in design on cart and/or bracket system for HLT (if 2 tier) (March)

Commit to RIMS or HERMS (March)

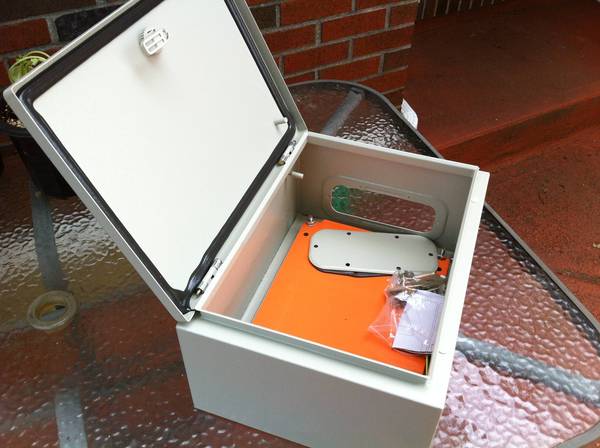

Build control panel (April/May)

Program BCS (JMay/June)

Sit on fat ass and waste time (July)

Inaugural brew (August/September)

I am open to suggestions, input, and loud yelling--so please feel free to suggest anything!!!

I’ve yet to decide on RIMS or HERMS….I know, I know…but I’ve been fully committed to doing each at one point or another. They both appeal to me—I don’t want to turn this into a RIMS vs. HERMS thread but the truth is I could be swayed either way. I was literally set to pop on the Brewer’s Hardware RIMS until this weekend. Watching my club’s low tech use of HERMS to hold mash temp on a 90-100gal mash convinced me that this is a very basic process.

I’ll probably have to decide in a few weeks. If I go RIMS, I am using the Brewer’s Hardware product; if HERMS it would likely be one that is not hard plumbed, over side if the keg and removable.

So…what’s the general project goals?

-Be able to handle 5-10 gallon batches

-Three 15.5 gallon Sanke vessels--2 untouched, one in use today

-Be able to fly sparge

-All weldless

-Keggles have to be removed from the setup for storage. (semi-permanent)

-Bottom drains on the MLT and BK. The HLT already has a diptube. I made a great 2x2000w/110v boil kettle a few months ago to get off the stovetop.

Will probably convert this to 220w and plug the other hole

-I turned my old immersion chiller into a CFC and will use that to chill until I have the funds for a plate chiller.

My house is fed by a 100amp main panel in the basement with a 60amp subpanel upstairs

Main Panel (basement)

Sub panel (upstairs)

Not sure why they had two panels (house is small) but there are lots of spaces in the main panel. There’s not a 220 circuit in the house. I hope I am not heading to an overload situation but my plan is to drop a 50W spa panel right off the main panel and manually limit my amperage draw elsewhere in the house. I think it should fairly easy not to run high amperage while brewing. Being an early riser, I usually start brewing before daylight and finish by Noon. We plan on upgrading to 200 amp service with central air, but not for a while.

The panel is about 30 feet away from my brewing area. On brew day, pretty sure I will have to run an RV cord to the control panel. Basement is completely finished—no permanent installation will permit a finished setup without a high degree of wall cutting or conduit.

I grabbed this cart at Costco for around $129, I can use this for a two vessels or deploy it elsewhere.

I may hang the HLT on the wall with removable brackets. Still not 100% sure. Space is at a premium, so I would like the ability to remove all the keggles to my furnace room for storage when we have parties. Using the cart probably meets chopping a few inches off the legs and punching two 1” holes through the surface for the bottom drains. If done right, there is no reason these holes can’t be covered/capped and the table mostly repurposed for use during parties.

The game plan:

Move router, fish 50 ft of RJ45-DONE

Replace analog probes with sensors and run first brew with BCS monitoring/logging via iPhone-DONE

Cut kegs and plumb bottom drains/valves (ordered parts) (late Feb)

Rig up Spa Panel and build a 220v outlet into it. (late Feb)

Rough in design on cart and/or bracket system for HLT (if 2 tier) (March)

Commit to RIMS or HERMS (March)

Build control panel (April/May)

Program BCS (JMay/June)

Sit on fat ass and waste time (July)

Inaugural brew (August/September)

I am open to suggestions, input, and loud yelling--so please feel free to suggest anything!!!

Last edited by a moderator: