Sparky

Well-Known Member

Just started this build and hope to get some input on the design, mainly need to make sure I have the right relay (see schematic).

Background

I typically take 45-60min for a 5 gallon batch to sparge and up to 2 hours for bigger batches. Adjusting the input/output of the sparge is tedious - I have better things to do than constantly tweeking the valves during this phase. I wanted to build an auto sparge system with the following requirements:

- Non-penetrating of kettle

- Measurement system that will not be in the mash kettle (cleaning, contamination, clogging)

- Easy adjustments

- Reasonably priced components

Solution

For the reasons mentioned above, I wanted to avoid the Blichman auto-sparge and general float switches.

I noticed on HBT that someone mentioned Omron had a site level sensor, but subsequent messages on HBT yielded no results of someone actually doing a build.

However, I was able to find the liquid level sensor from Omron (picture below):

http://www.ia.omron.com/products/family/475/

I have a Blichman 20gal tank and was able to remove the outer (metal) measurement guide. The site glass is 15mm so the E2K-L26MC1 was the appropriate size. These sensors are a NO operation mode. The premise is that they will turn on/off the pump, based on the level of liquid in the site glass. They are easily attached via small zip tie and can be slid up/down the site glass. They can be attached with a separation of >1 3/8" (>35mm), which is perfect for a liquid level bed.

Wiring

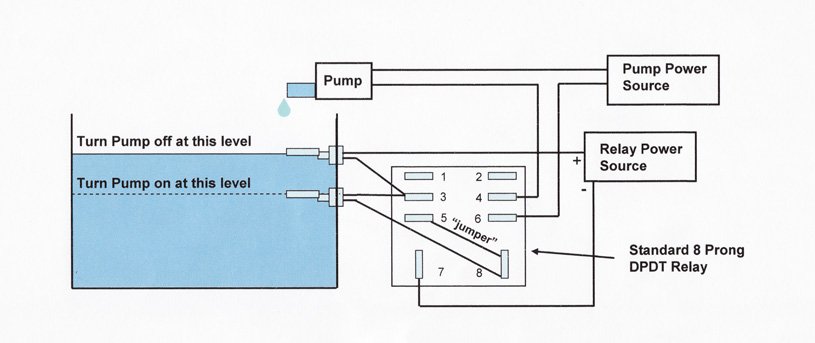

See the attached wiring diagram below. I am not sure about the correct relay since I cannot find a wiring diagram of one.

I will be controlling the pump on/off via the two sensors. The relay will be able to handle 120V output so an SSR is not needed.

If someone could help out with the appropriate relay, that would be great.

Cost

(2) used Omron E2K-L26MC1 = $40

(1) relay/base = $25

wiring/plugs = $6

Total cost = ~$71

Photo at bottom of page is existing setup (before any mod).

Background

I typically take 45-60min for a 5 gallon batch to sparge and up to 2 hours for bigger batches. Adjusting the input/output of the sparge is tedious - I have better things to do than constantly tweeking the valves during this phase. I wanted to build an auto sparge system with the following requirements:

- Non-penetrating of kettle

- Measurement system that will not be in the mash kettle (cleaning, contamination, clogging)

- Easy adjustments

- Reasonably priced components

Solution

For the reasons mentioned above, I wanted to avoid the Blichman auto-sparge and general float switches.

I noticed on HBT that someone mentioned Omron had a site level sensor, but subsequent messages on HBT yielded no results of someone actually doing a build.

However, I was able to find the liquid level sensor from Omron (picture below):

http://www.ia.omron.com/products/family/475/

I have a Blichman 20gal tank and was able to remove the outer (metal) measurement guide. The site glass is 15mm so the E2K-L26MC1 was the appropriate size. These sensors are a NO operation mode. The premise is that they will turn on/off the pump, based on the level of liquid in the site glass. They are easily attached via small zip tie and can be slid up/down the site glass. They can be attached with a separation of >1 3/8" (>35mm), which is perfect for a liquid level bed.

Wiring

See the attached wiring diagram below. I am not sure about the correct relay since I cannot find a wiring diagram of one.

I will be controlling the pump on/off via the two sensors. The relay will be able to handle 120V output so an SSR is not needed.

If someone could help out with the appropriate relay, that would be great.

Cost

(2) used Omron E2K-L26MC1 = $40

(1) relay/base = $25

wiring/plugs = $6

Total cost = ~$71

Photo at bottom of page is existing setup (before any mod).