Bitterbrush

Well-Known Member

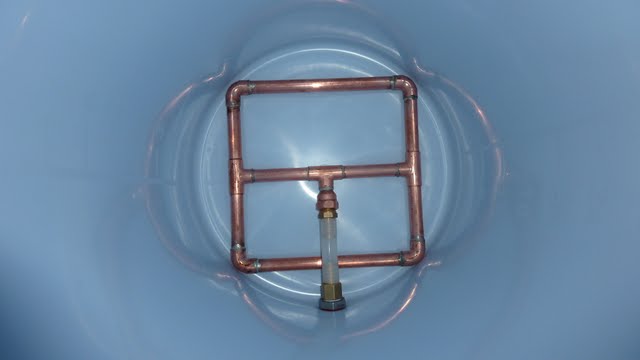

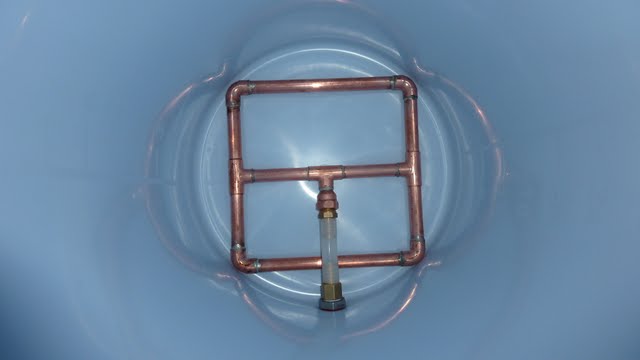

I have had a few requests for instructions on how to make the manifold for my Rubbermaid cooler from Home Depot, so here you go. This type of manifold has been shown here before so I can't take credit for the original design. This works really good for me, never have had a stuck sparge with batch sparging. I'm sure it would work equally as well fly sparging also.

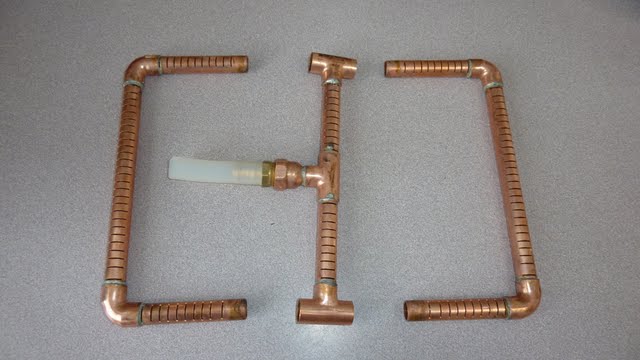

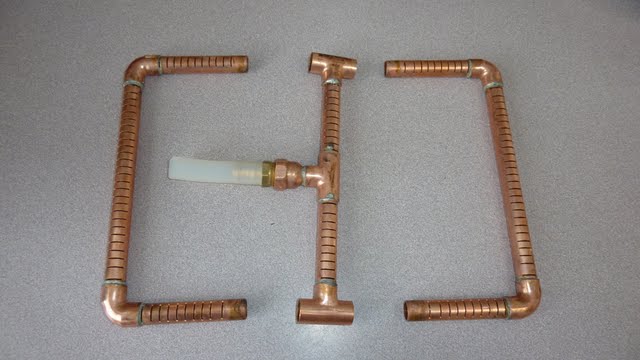

I soldered the sides and center of this thing together so there wouldn't be so many pieces to take apart when cleaning, it's very easy to clean. The center T is soldered at an angle up so the tubing can attach to the bulkhead hose barb. The slits are 1/4" apart. I just clamped the tubing gently in my bench vise and left about half of it sticking up out of the vise jaws, then using a 32t hacksaw blade I just went at all the 1/4" marks made on the tubing. Just don't squeeze it to tight or you will have egg shaped tubing.

My bulkhead fitting has a 1/2" stainless nipple going through the cooler wall so I just attached the female npt x hose barb to the back of it. Everything was bought at Lowes except the bulkhead assembly and the silcone tubing. The bulkhead and tubing I got from Bargainfittings.com

Materials list:

2- 7 7/8" 1/2" type M cu pipe

6- 3 9/16"

4- 90's

3- T's

1- 1/2" female NPT x 1/2" male cu adapter

1- 1/2" male NPT x 1/2" hose barb brass

1- 1/2" female NPT x 1/2" hose barb brass

1- 1/2" ID silicone tubing x 3"

I soldered the sides and center of this thing together so there wouldn't be so many pieces to take apart when cleaning, it's very easy to clean. The center T is soldered at an angle up so the tubing can attach to the bulkhead hose barb. The slits are 1/4" apart. I just clamped the tubing gently in my bench vise and left about half of it sticking up out of the vise jaws, then using a 32t hacksaw blade I just went at all the 1/4" marks made on the tubing. Just don't squeeze it to tight or you will have egg shaped tubing.

My bulkhead fitting has a 1/2" stainless nipple going through the cooler wall so I just attached the female npt x hose barb to the back of it. Everything was bought at Lowes except the bulkhead assembly and the silcone tubing. The bulkhead and tubing I got from Bargainfittings.com

Materials list:

2- 7 7/8" 1/2" type M cu pipe

6- 3 9/16"

4- 90's

3- T's

1- 1/2" female NPT x 1/2" male cu adapter

1- 1/2" male NPT x 1/2" hose barb brass

1- 1/2" female NPT x 1/2" hose barb brass

1- 1/2" ID silicone tubing x 3"