You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

Yet more evidence that commercial brewers do not mash at 5.2 to 5.6 pH ...

- Thread starter Silver_Is_Money

- Start date

Help Support Homebrew Talk:

This site may earn a commission from merchant affiliate

links, including eBay, Amazon, and others.

Robert65

Major Obvious (recently promoted)

Recommended or possible? In my experience best practice is to acidify before adding kettle finings, so around 10 minutes to knockout, and this is what is supported by the professional literature. But indeed one question raised in this thread is whether there is significant harm in acidification earlier, as apparently this seems more convenient to some (I don't understand why.) I suppose some results will be reported of anyone tries it.For a hoppy beer without Pilsner malt (or any beer without risk of DMS), dosing at preboil is recommended?

Recommended or possible? In my experience best practice is to acidify before adding kettle finings, so around 10 minutes to knockout, and this is what is supported by the professional literature. But indeed one question raised in this thread is whether there is significant harm in acidification earlier, as apparently this seems more convenient to some (I don't understand why.) I suppose some results will be reported of anyone tries it.

The reason I dose my acid at the beginning of the boil is for control.

I’ll mash out to 170...remove the grain...then hold at 170 until I’ve dosed...taken a measurement and either dose again if needed to hit desired ph or start to raise the temp to boil.

Doing it towards the end when I’ve got hop additions, whirlfloc, and an immersion chiller to set up adds more to juggle.

If your saying there is a benefit to dosing at the end...then I’d be willing to try it.

And I like my beer as do others but that’s neither here nor there being subjective and possibly misguided.

Robert65

Major Obvious (recently promoted)

Having a lot to juggle and not having the luxury of testing and adjusting when doing a late addition is one reason why some of us have been working on good ways to predict/ calculate the required acid dose based on preboil pH. I have my own method (in flux) and @Silver_ Is_Money has developed a tool incorporated in Mash Made Easy. Give that a try if you're interested.

Die_Beerery

Well-Known Member

- Joined

- Aug 21, 2017

- Messages

- 842

- Reaction score

- 643

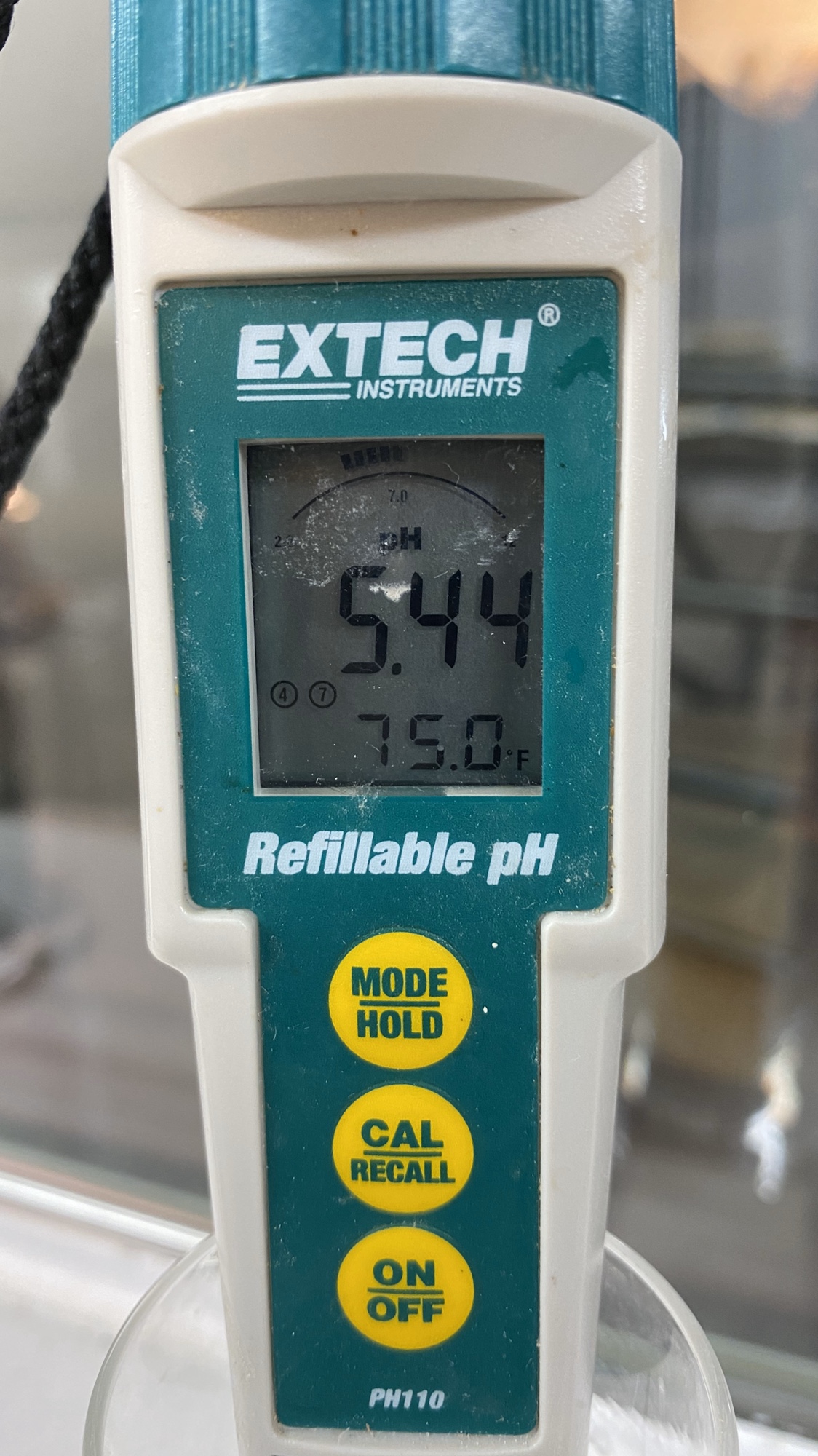

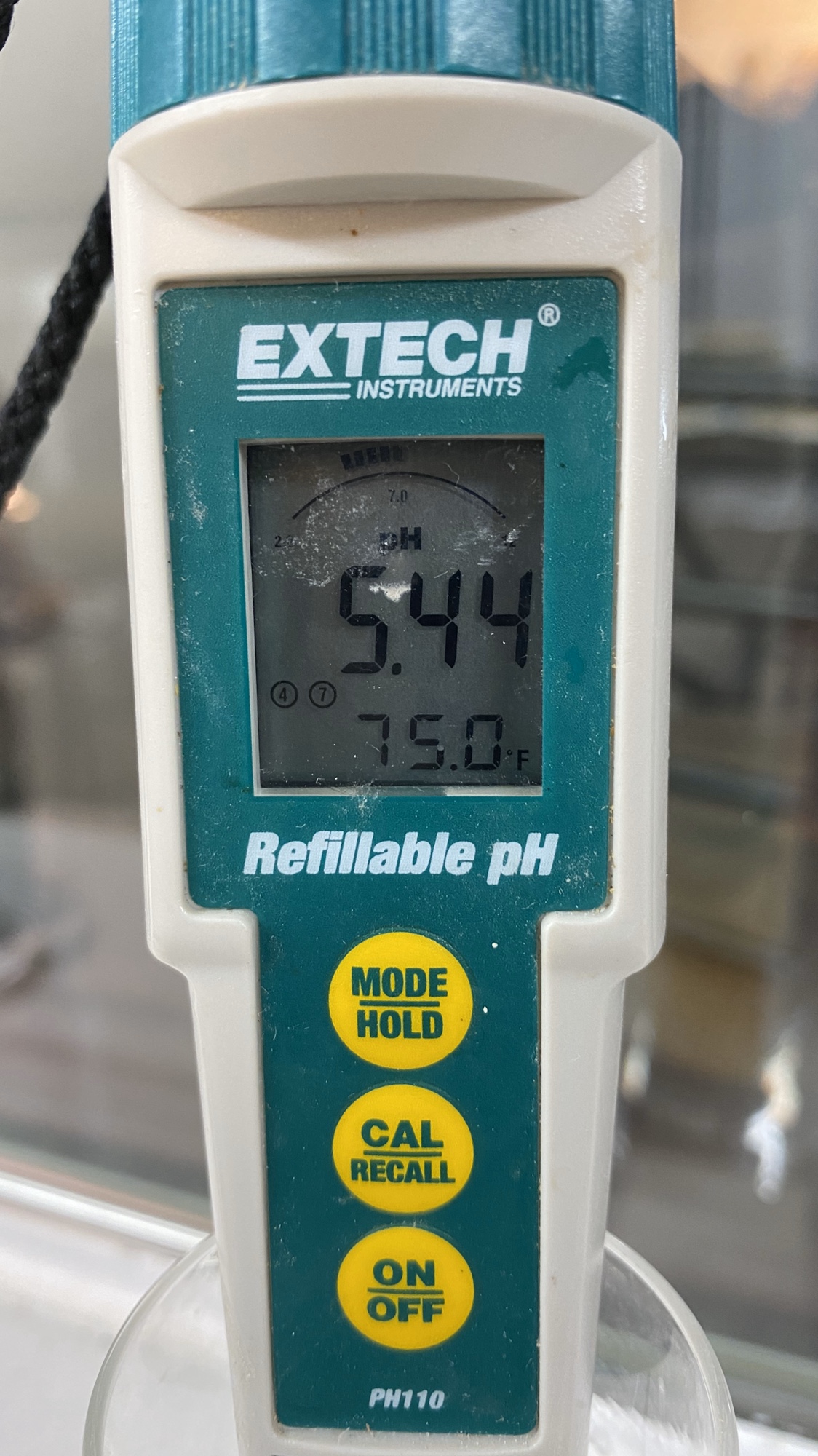

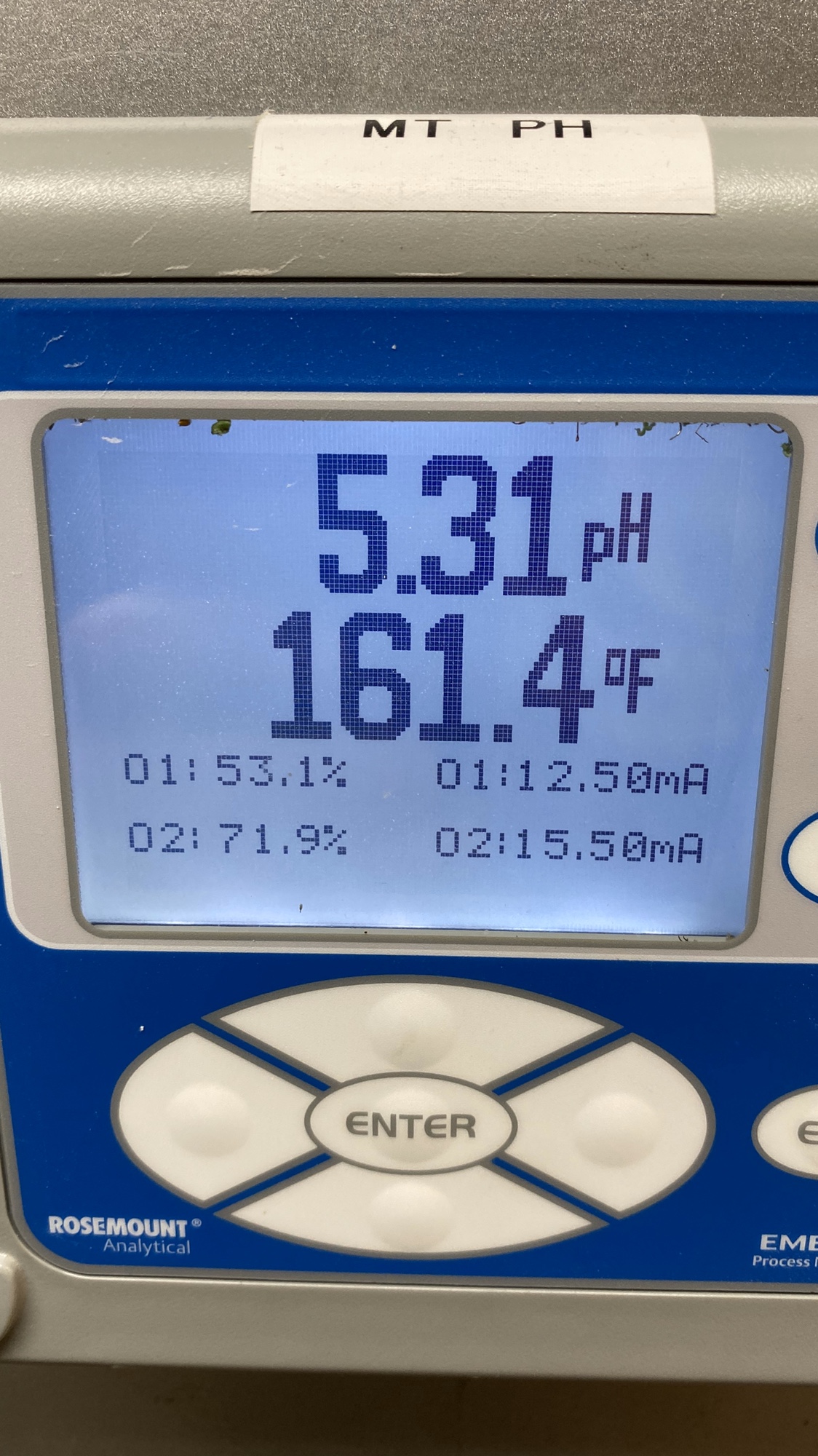

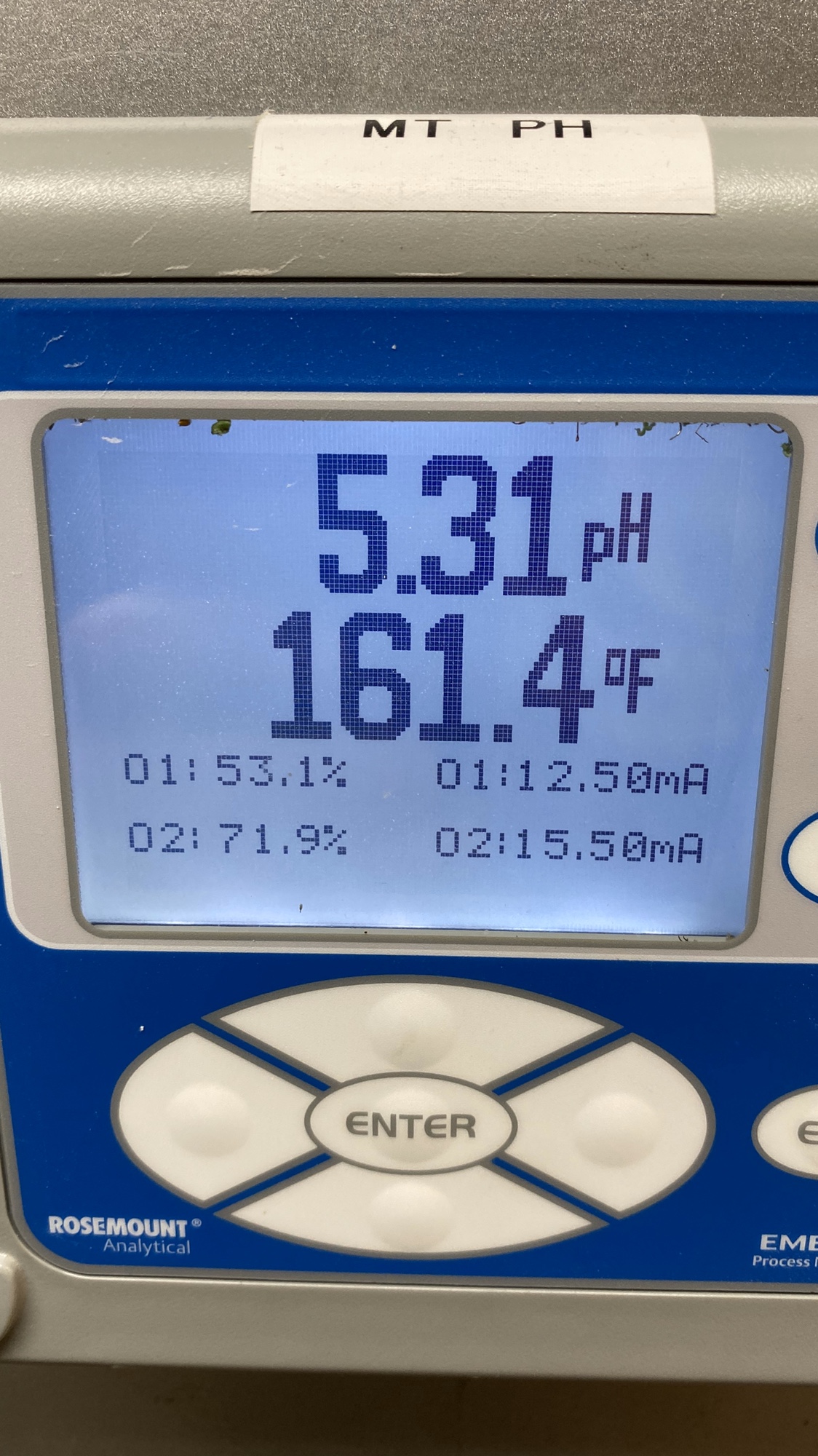

Been waiting for someone to post offsets. Guess I’m going to be that guy.

In process pH

Room temp pH

Looks like my offset (@ 140f) is .15. My point being, homebrew dogma is ********.

In process pH

Room temp pH

Looks like my offset (@ 140f) is .15. My point being, homebrew dogma is ********.

Silver_Is_Money

Larry Sayre, Developer of 'Mash Made Easy'

Looks like the offset from 70 degrees to 155 degrees would be on the order of 0.2 points based upon your meters. A bit lower than I would have anticipated, but still significant. Thanks for posting this!

$479.00

$559.00

EdgeStar KC1000SS Craft Brew Kegerator for 1/6 Barrel and Cornelius Kegs

Amazon.com

$39.22 ($39.22 / Count)

Brewer's Best Home Brew Beer Ingredient Kit - 5 Gallon (Mexican Cerveza)

Amazon.com

$7.79 ($7.79 / Count)

Craft A Brew - LalBrew Voss™ - Kveik Ale Yeast - For Craft Lagers - Ingredients for Home Brewing - Beer Making Supplies - (1 Pack)

Craft a Brew

$2.41

$29.95

Mastering Homebrew: The Complete Guide to Brewing Delicious Beer (Beer Brewing Bible, Homebrewing Book)

Clickgoodwill

$22.00 ($623.23 / Ounce)

AMZLMPKNTW Ball Lock Sample Faucet 30cm Reinforced Silicone Hose Secondary Fermentation Homebrew Kegging joyful

无为中南商贸有限公司

$10.99 ($31.16 / Ounce)

Hornindal Kveik Yeast for Homebrewing - Mead, Cider, Wine, Beer - 10g Packet - Saccharomyces Cerevisiae - Sold by Shadowhive.com

Shadowhive

![Craft A Brew - Safale S-04 Dry Yeast - Fermentis - English Ale Dry Yeast - For English and American Ales and Hard Apple Ciders - Ingredients for Home Brewing - Beer Making Supplies - [1 Pack]](https://m.media-amazon.com/images/I/41fVGNh6JfL._SL500_.jpg)

$6.95 ($17.38 / Ounce)

$7.47 ($18.68 / Ounce)

Craft A Brew - Safale S-04 Dry Yeast - Fermentis - English Ale Dry Yeast - For English and American Ales and Hard Apple Ciders - Ingredients for Home Brewing - Beer Making Supplies - [1 Pack]

Hobby Homebrew

$53.24

1pc Hose Barb/MFL 1.5" Tri Clamp to Ball Lock Post Liquid Gas Homebrew Kegging Fermentation Parts Brewer Hardware SUS304(Gas MFL)

Guangshui Weilu You Trading Co., Ltd

$58.16

HUIZHUGS Brewing Equipment Keg Ball Lock Faucet 30cm Reinforced Silicone Hose Secondary Fermentation Homebrew Kegging Brewing Equipment

xiangshuizhenzhanglingfengshop

$176.97

1pc Commercial Keg Manifold 2" Tri Clamp,Ball Lock Tapping Head,Pressure Gauge/Adjustable PRV for Kegging,Fermentation Control

hanhanbaihuoxiaoshoudian

$53.24

1pc Hose Barb/MFL 1.5" Tri Clamp to Ball Lock Post Liquid Gas Homebrew Kegging Fermentation Parts Brewer Hardware SUS304(Liquid Hose Barb)

yunchengshiyanhuqucuichendianzishangwuyouxiangongsi

Die_Beerery

Well-Known Member

- Joined

- Aug 21, 2017

- Messages

- 842

- Reaction score

- 643

Not so fast.

Calibration status - how recent? These things can drift like mad.

Die_Beerery

Well-Known Member

- Joined

- Aug 21, 2017

- Messages

- 842

- Reaction score

- 643

Calibration status - how recent? These things can drift like mad.

Come on now... you know I calibrate religiously.

Robert65

Major Obvious (recently promoted)

But, generally greater displacements are not merely homebrew dogma, but attested in the scientific literature -- with the caveat that there is no universal constant (that is the homebrew dogma part,) but that the displacement is influenced by many factors (which homebrewers can't seem to get their heads around.) Would you care to speculate, Bryan, as to whether there might be something about your system that leads to a lesser displacement than is commonly observed? Your system, you'll no doubt admit, does not provide the conditions found in either conventional brewery outfits or laboratory tests.

Bryan:

At what temp do you calibrate the mash pH probe?

At what temp do you calibrate the mash pH probe?

Silver_Is_Money

Larry Sayre, Developer of 'Mash Made Easy'

To more properly gauge any individual pH meters inherent pH differential one must use the very same pH meter and measure the pH at two different temperatures (room and mash) with it.

To more properly gauge any individual pH meters inherent pH differential one must use the very same pH meter and measure the pH at two different temperatures (room and mash) with it.

I'll agree. The temperature effects are so damned fussy and data so scattered that given Bryan's data points above (and yes I do believe he is a very trustworthy source), now I don't know what the frick to believe anymore. Is the adjustment 0.1, 0.25, 0.18, 0.22, 0.2, 0.17..... who the frick knows. And what's more....... does it even really matter all that much!? That is the ultimate question that will never receive a consistent answer.

Thank you to Bryan for these specific new data points. And yes I'm sure you calibrate like a fiend. Personally I calibrate every time I use the thing, both before and after the brew session, that's what gives me confidence that heck at least I'm trying.

Die_Beerery

Well-Known Member

- Joined

- Aug 21, 2017

- Messages

- 842

- Reaction score

- 643

Bryan:

At what temp do you calibrate the mash pH probe?

Room temp.

Die_Beerery

Well-Known Member

- Joined

- Aug 21, 2017

- Messages

- 842

- Reaction score

- 643

But, generally greater displacements are not merely homebrew dogma, but attested in the scientific literature -- with the caveat that there is no universal constant (that is the homebrew dogma part,) but that the displacement is influenced by many factors (which homebrewers can't seem to get their heads around.) Would you care to speculate, Bryan, as to whether there might be something about your system that leads to a lesser displacement than is commonly observed? Your system, you'll no doubt admit, does not provide the conditions found in either conventional brewery outfits or laboratory tests.

Well, I highly doubt it. Only thing being I have zero DO. DO does play a role in ORP and redox, which could alter pH, but it should have no effect on differential.

Die_Beerery

Well-Known Member

- Joined

- Aug 21, 2017

- Messages

- 842

- Reaction score

- 643

I'll agree. The temperature effects are so damned fussy and data so scattered that given Bryan's data points above (and yes I do believe he is a very trustworthy source), now I don't know what the frick to believe anymore. Is the adjustment 0.1, 0.25, 0.18, 0.22, 0.2, 0.17..... who the frick knows. And what's more....... does it even really matter all that much!? That is the ultimate question that will never receive a consistent answer.

Thank you to Bryan for these specific new data points. And yes I'm sure you calibrate like a fiend. Personally I calibrate every time I use the thing, both before and after the brew session, that's what gives me confidence that heck at least I'm trying.

My meters are anything but. I have solid expensive meters. I can go months with them sitting and do a calibration, and they will be within .01. I still calibrate before every session, and after (since the solution is still out) to make sure nothing went wonky.

The answer for me is... pH is going to track and sway along the range. Chasing that is a fruitless effort. So for me I target a pH at dough in which I know my offset for. My mashes are all the same, with the same grains so for me that’s 131f.

Then 144

147

151

163

170

Upon dough in I target 5.25 mash temp which for me is 5.4 room temp. Once I get into beta pH will shift up a tad to around 5.29, then settle around there. That’s what’s constant for me. What’s not constant is my offset it seems to raise and lower and would be impossible to chase. So for me and my setup. This is what I do.

Well, I highly doubt it. Only thing being I have zero DO. DO does play a role in ORP and redox, which could alter pH, but it should have no effect on differential.

I agree, DO or lack thereof should not affect pH, not counting the odd redux things that may be happening in parallel depending on what solution is being measured (plain water vs. wort for example).

Upon dough in I target 5.25 mash temp which for me is 5.4 room temp. Once I get into beta pH will shift up a tad to around 5.29, then settle around there. That’s what’s constant for me. What’s not constant is my offset it seems to raise and lower and would be impossible to chase. So for me and my setup. This is what I do.

THANK YOU. This is the kind of information I've wanted to hear from you. Cheers!

Silver_Is_Money

Larry Sayre, Developer of 'Mash Made Easy'

The Weyermann publication titled "pH In The Brewery" offers confirmation as to why it isn't likely the best practice to mash at between 5.2 and 5.6 pH as measured at room temperature. Notice that the principle enzymes of our concern are at their peak of performance at high pH's as measured at their respective optimal temperatures. If we add a pH meter correction factor of 0.25 to better reflect these pH's at room temperature we get 5.65 to 5.85 pH as the optimal range for Beta-Amylase, and 5.85 to 6.05 as the optimal range for Alpha-Amylase. This lends support to the position behind this thread that the "ideal room temperature mash pH range" should be revised upward from the currently accepted 5.2-5.6 pH to 5.5-5.9 pH.

"pH In The Brewery" can be downloaded at this link:

https://aussiedistiller.com.au/books/Whiskyaugogo/Weyermann_TKW_Mash-pH_2010.pdf

"pH In The Brewery" can be downloaded at this link:

https://aussiedistiller.com.au/books/Whiskyaugogo/Weyermann_TKW_Mash-pH_2010.pdf

Fwiw (probably nothing), I’ve mashed at 5.65 (room temperature) for my last four batches instead of my usual 5.4 (room temperature), and my efficiency has suffered a significant hit. Upwards of 5 gravity points. Now, maybe that hit is worth it if it results in better beer. But it sure doesn’t seem like the enzymes are working better *for me*.

I picked the wrong series of beers to test this on (British beers). I might need to try again with Helles to get a real understanding of how beer quality is affected.

Anecdotal and unscientific for sure, but in my brewery, I’m ready to state the higher pH is less efficient (but not necessarily worse for the beer).

I picked the wrong series of beers to test this on (British beers). I might need to try again with Helles to get a real understanding of how beer quality is affected.

Anecdotal and unscientific for sure, but in my brewery, I’m ready to state the higher pH is less efficient (but not necessarily worse for the beer).

Silver_Is_Money

Larry Sayre, Developer of 'Mash Made Easy'

Fwiw (probably nothing), I’ve mashed at 5.65 (room temperature) for my last four batches instead of my usual 5.4 (room temperature), and my efficiency has suffered a significant hit. Upwards of 5 gravity points. Now, maybe that hit is worth it if it results in better beer. But it sure doesn’t seem like the enzymes are working better *for me*.

I picked the wrong series of beers to test this on (British beers). I might need to try again with Helles to get a real understanding of how beer quality is affected.

Anecdotal and unscientific for sure, but in my brewery, I’m ready to state the higher pH is less efficient (but not necessarily worse for the beer).

I wouldn't have expected efficiency to decrease. Thanks for sharing this.

hopjuice_71

Well-Known Member

- Joined

- Mar 26, 2016

- Messages

- 373

- Reaction score

- 374

Just to provide a different data point....I stopped adjusting the pH of my mash down to ~5.4 using acid. I just use the salts I want and I get a mash pH that settles in around 5.6-5.7 at 20 minutes. Seems to end up at around 5.4-5.5 by the end of a 1 hour mash. All room temp measurements. My efficiency has increased by about 5%. I adjust the kettle pH with acid - using Mash Made Easy to give me the estimates - thank you @Silver_Is_Money!

Edit: forgot to mention that I use tap water, but what comes out of my tap is as close to RO as you will get out of a public water source.

Edit: forgot to mention that I use tap water, but what comes out of my tap is as close to RO as you will get out of a public water source.

Damn, science is a harsh mistress. Thank you, @hopjuice_71, for your report. I guess I'll try going back to 5.4 and seeing if things snap back. Again, we don't want to assume efficiency correlates with better beer, so I guess I won't be convinced until I try this with Helles (my personal pinnacle of styles).

Bilsch

Well-Known Member

- Joined

- May 4, 2015

- Messages

- 1,754

- Reaction score

- 1,609

Fwiw (probably nothing), I’ve mashed at 5.65 (room temperature) for my last four batches instead of my usual 5.4 (room temperature), and my efficiency has suffered a significant hit. Upwards of 5 gravity points. Now, maybe that hit is worth it if it results in better beer. But it sure doesn’t seem like the enzymes are working better *for me*.

You are not alone. Last two batches I shifted up from 5.4 RT to 5.6 and took a 1p hit.

hopjuice_71

Well-Known Member

- Joined

- Mar 26, 2016

- Messages

- 373

- Reaction score

- 374

Damn, science is a harsh mistress. Thank you, @hopjuice_71, for your report. I guess I'll try going back to 5.4 and seeing if things snap back. Again, we don't want to assume efficiency correlates with better beer, so I guess I won't be convinced until I try this with Helles (my personal pinnacle of styles).

Indeed it is.. ..and it happens to be my day job, so I have taken a lot of abuse

hopjuice_71

Well-Known Member

- Joined

- Mar 26, 2016

- Messages

- 373

- Reaction score

- 374

You are not alone. Last two batches I shifted up from 5.4 RT to 5.6 and took a 1p hit.

Hmm, interesting. Could my gain and others losses have anything to do with type of malt?

Possibly. I have seen reports that some malts can have higher gelatinization temperatures than other malts. This can affect your conversion efficiency, which then affects mash efficiency, and all other downstream efficiencies. I've been thinking that the way to deal with such malts is to raise the mash temp up to 170°F, and rest for a while, then drop the temp and add alpha amylase to complete conversion. Or, you can just accept the lower eff.Hmm, interesting. Could my gain and others losses have anything to do with type of malt?

Brew on

wrt pH 5.8 - isn't that verging on the threshold of releasing tannins from husks, especially given the duration [edit: and temperature] of a typical mash?

Cheers!

[tried to catch up on this thread, realized this was only the second use of the word "tannin" in the entire thread.]

Cheers!

[tried to catch up on this thread, realized this was only the second use of the word "tannin" in the entire thread.]

Last edited:

Might be. The rate limiting step in saccharification is the gelatinization of the starch granules. Once the starch is gelatinized, the hydrolysis, catalyzed by the amylase enzymes, is pretty fast. I have not seen anything that says pH affects the gelatinization rate, but then I haven't looked. IMO optimizing pH for amylase activity is not what needs to be addressed to improve conversion efficiency. The previous has nothing to do with pH affects on beer flavor.wrt pH 5.8 - isn't that verging on the threshold of releasing tannins from husks, especially given the duration [edit: and temperature] of a typical mash?

Cheers!

Brew on

hopjuice_71

Well-Known Member

- Joined

- Mar 26, 2016

- Messages

- 373

- Reaction score

- 374

....The previous has nothing to do with pH affects on beer flavor.

Agreed. Maybe I have just been lucky with my non-optimization of mash pH and an increase in efficiency. However, my beer has improved by adjustment of the kettle pH with acid.

Similar threads

- Replies

- 7

- Views

- 1K

- Replies

- 6

- Views

- 1K

- Replies

- 6

- Views

- 1K

- Replies

- 17

- Views

- 5K