evilshatner

New Member

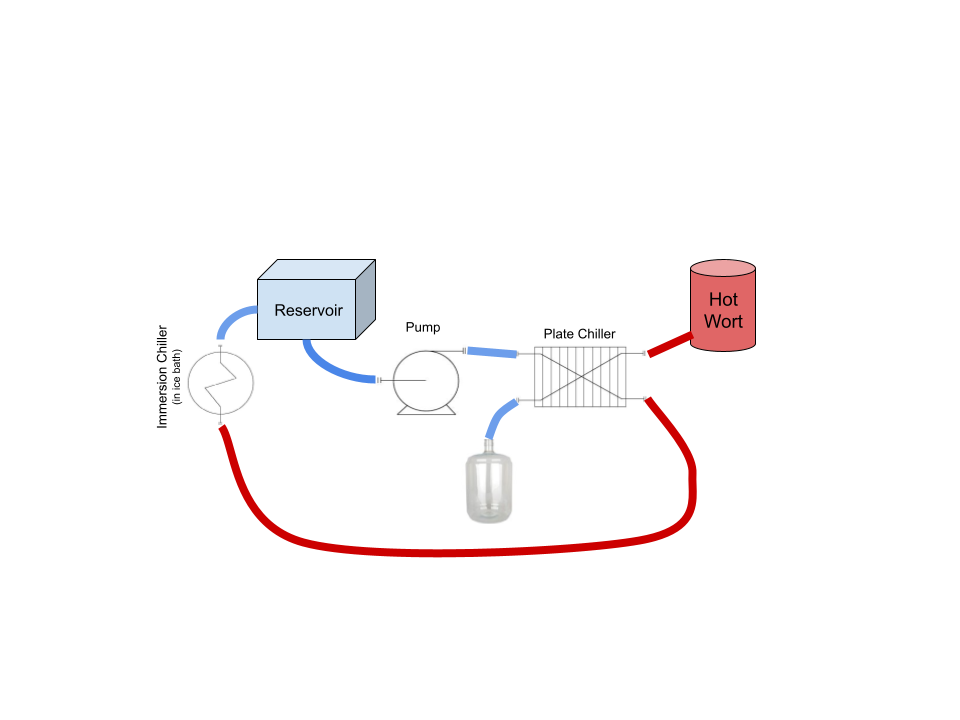

Being from drought stricken California, most of the effective wort cooling methods require A LOT of water which just isn't awesome. After a bit of trial and error, I have come up with a system that utilizes an immersion chiller in an ice bath (looking to do better), a plate chiller for the wort and a variable rate marine pump to control the flow of chilled water.

It takes about 28lbs of ice and 1 gallon of water to chill 5 gallons of wort in ~18 minutes.

Below is a quick and dirty drawing of the setup.

I'd love for people to comment on the design and help me improve upon it.

The next thing for me to figure out is: Icy water eventually heats up enough that it becomes nearly ineffective to chill the wort, so what are some other cost effective options?

It takes about 28lbs of ice and 1 gallon of water to chill 5 gallons of wort in ~18 minutes.

Below is a quick and dirty drawing of the setup.

- The reservoir is used to bleed air out of the system while continually providing the pump with air-free water

- The immersion chiller sits in an ice bath

- Priming time: ~5 min

I'd love for people to comment on the design and help me improve upon it.

The next thing for me to figure out is: Icy water eventually heats up enough that it becomes nearly ineffective to chill the wort, so what are some other cost effective options?