Jeez. Yea, you're absolutely correct. It made a lot of sense to me when I did it, but rereading it today...my questions don't make a whole lot of sense. To clarify...

I'm currently brewing extracts and 3 gallon biab kits from NB. I made a fermentation chamber with an stc 1000 and I enjoyed it. I don't have a big budget, but I'd like to be able to do full grain biab, with the eventual ability to make it all electric for mashing. In other words, I envision being able to use my propane burner to bring full boil up to mash temp, then use a rims and recirculating system to maintain temps. Once mash was complete, I'd turn the propane burner back on for the boil. My thought is that this would allow me to use 110/120 instead of 240. I'm in a rental house and that much energy, plus water, scares me.

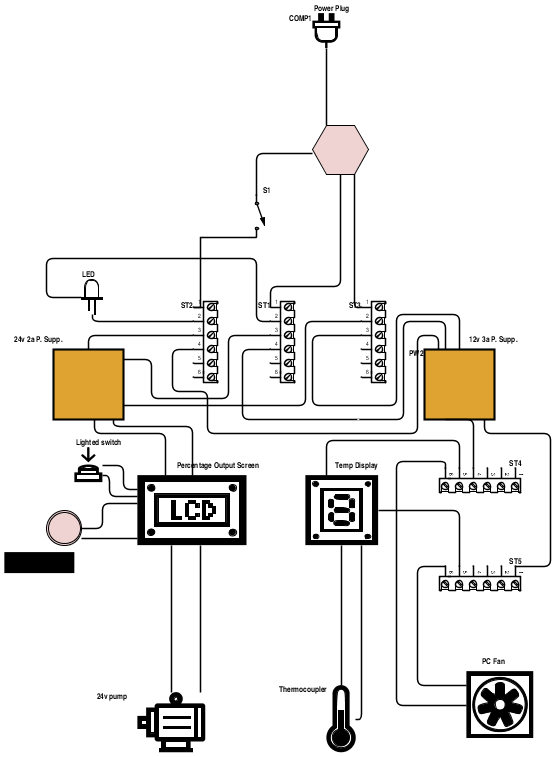

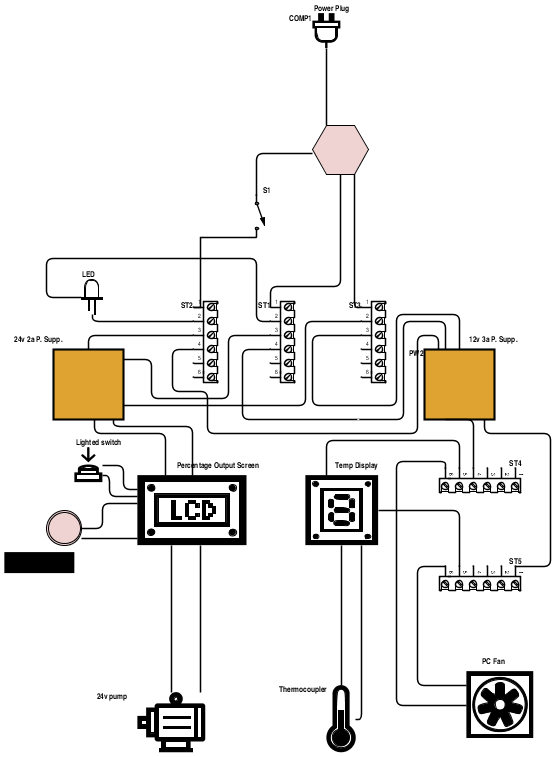

So, back to the schematic. From my research, the 24v cheap eBay pump has a flow rate of about 190 gph....about double the 12v. The only extra expense would be about $10 for a 24v power supply. device between the 24v supply and the pump on the schematic is a potentiometer/percentage digital display/on-off button for sale on eBay for about 9 bucks. The thought there is that I can control the flow much more accurately than with the valve on the pot.

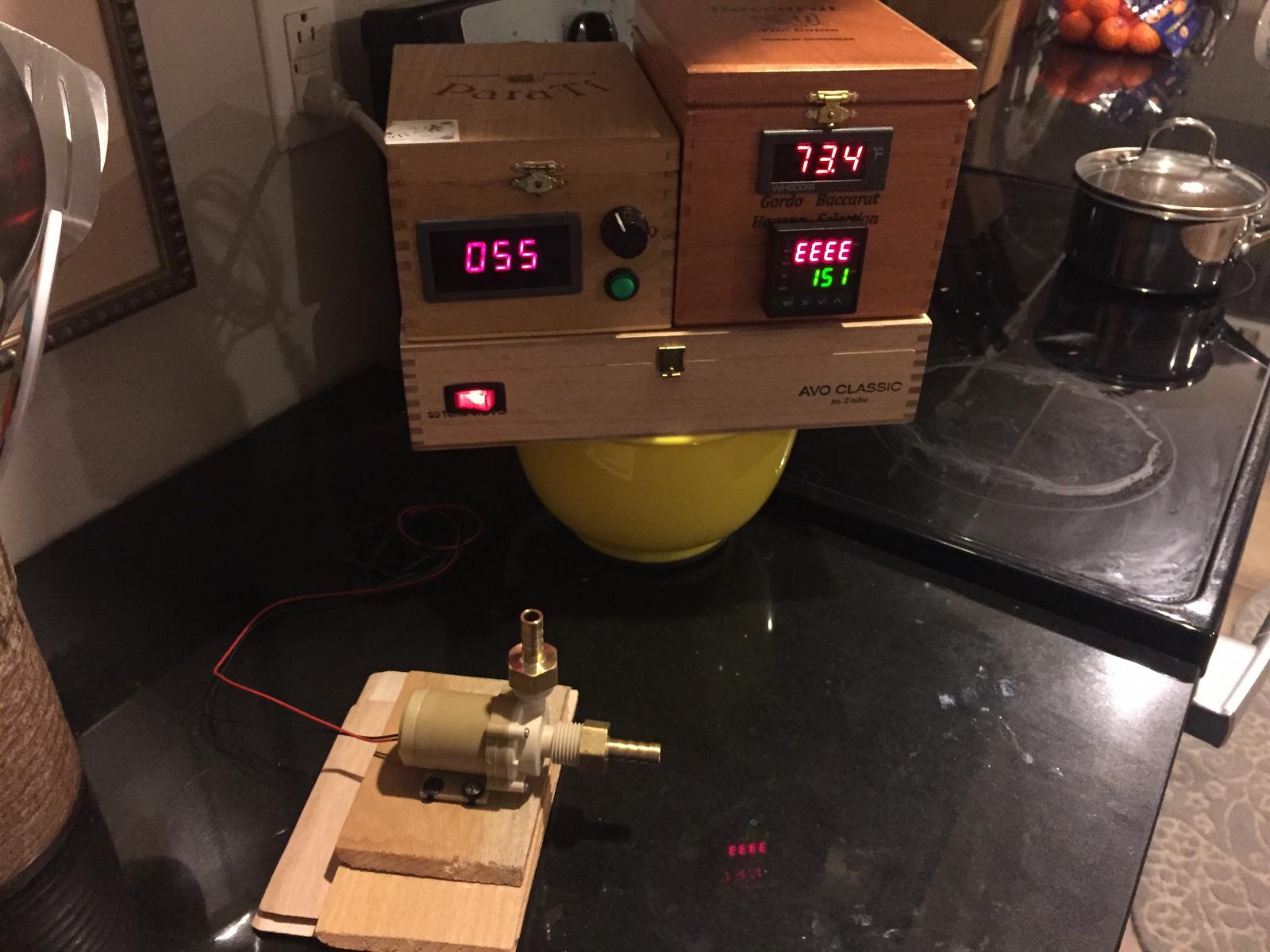

As to the 12v wiring, my thought was that two device will pull from that power supply. 1- a digital thermometer with a thermocoupler (plugged into the open end of a sight glass) and 2- a $1.00 of fan to keep it cool (I'm planning on putting this in a large cigar box, painted with kilz).

Later, when I have a little more money, I want to build a low budget rims system powered by 110/120, pushed by this cheapo pump. Again, this would just be to maintain temps. All controlled by a PID.

Then, I plan to buy an immersion chiller with a whirlpool arm.

As to kettle, I've bought a concord 15g stainless pot, a weldless valve, a pickup tube, and a sight glass with a "t" (so I can plug in my Thermocoupler. This way, I'll only have 2 holes in the kettle.

I really do believe a lot of folks would be interested if it works. It's pretty cheap, lets you control temps accurately, and should be able to do most 10g batches.

Thanks for any insight.

![Craft A Brew - Safale S-04 Dry Yeast - Fermentis - English Ale Dry Yeast - For English and American Ales and Hard Apple Ciders - Ingredients for Home Brewing - Beer Making Supplies - [1 Pack]](https://m.media-amazon.com/images/I/41fVGNh6JfL._SL500_.jpg)