lavinjj

Member

I just picked one up from the local Wal-Mart. It would be perfect for doing the small batches I want to do at competition time, 1 - 2 Gallons. However, I'm going to need to replace the temperature controller or hack it to get the type of temperature control I want.

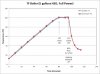

Right now it looks as if I can only have one temperature for the mash and that is 150 degrees F. It took 20 minutes to bring 4 gallons of water to temp which for me is perfect for a small batch.

The next step up is 170 degrees F which is fine for Mash Out, but It's not going to be good enough for the various recipes I want to brew. I want a range from 110-175 degrees, anything over that is pretty much inconsequential to me since, boiling would be the next logical step in the process.

The other thing I noticed is the temperature differential is about 5 degrees before the unit kicks back on. This needs to be tightened up quite a bit for what I want.

Overall, I think with a little hacking of the Temperature Controller or by replacing it totally I think it will make a really nice mini-biab vessel with the addition of a pump to recirculate the wort to even out the temperature across the batch during mashing.

So, it looks like I got a little work to do over the next week or so to get it to where I want it.

Jim Lavin

http://otakubrewing.com

Right now it looks as if I can only have one temperature for the mash and that is 150 degrees F. It took 20 minutes to bring 4 gallons of water to temp which for me is perfect for a small batch.

The next step up is 170 degrees F which is fine for Mash Out, but It's not going to be good enough for the various recipes I want to brew. I want a range from 110-175 degrees, anything over that is pretty much inconsequential to me since, boiling would be the next logical step in the process.

The other thing I noticed is the temperature differential is about 5 degrees before the unit kicks back on. This needs to be tightened up quite a bit for what I want.

Overall, I think with a little hacking of the Temperature Controller or by replacing it totally I think it will make a really nice mini-biab vessel with the addition of a pump to recirculate the wort to even out the temperature across the batch during mashing.

So, it looks like I got a little work to do over the next week or so to get it to where I want it.

Jim Lavin

http://otakubrewing.com