brandona33

Well-Known Member

- Joined

- Feb 24, 2008

- Messages

- 83

- Reaction score

- 0

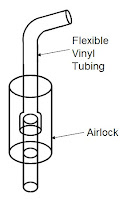

My latest brew is in the Primary since Wednesday 2/27 and was bubbling away nicely. This morning I woke to see the foam from the surface had worked up into my airlock, stopping the bubbling, and then seeped up through the hole in the lid for the airlock. After inspecting the area, I saw the grommit was bad and it wasn't a tight seal. Was this the culprit?

I pulled the airlock out, careful not to have the water in it wash into the brew, then pulled the lid off. washed all parts thoroughly, sanitized and put back together with a new grommit. Will being exposed to oxygen do anything, and should I be concerned?

Thanks

I pulled the airlock out, careful not to have the water in it wash into the brew, then pulled the lid off. washed all parts thoroughly, sanitized and put back together with a new grommit. Will being exposed to oxygen do anything, and should I be concerned?

Thanks