You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

Why can’t I use…

- Thread starter Grond

- Start date

Help Support Homebrew Talk:

This site may earn a commission from merchant affiliate

links, including eBay, Amazon, and others.

No idea. Did someone say you couldn't? Get it wired correctly and safely and take it for a spin.

Do you have one laying around? Could be a fun project. If you're starting from scratch, you might consider pre-made solutions. But don't have to.

Do you have one laying around? Could be a fun project. If you're starting from scratch, you might consider pre-made solutions. But don't have to.

sicktght311

Well-Known Member

- Joined

- Oct 16, 2018

- Messages

- 686

- Reaction score

- 304

Can you? Sure! Should you? depends

At the end of the day, an electric water heater thermostat does the same thing as a full brewerry controller.........it turns an element on and off to achieve a desired temperature.

However while a water heater T-stat might be set to "120", the actual temperature is probably plus or minus 10 degrees if its not an accurate digital Pid controlled thermostat, and is instead one of those ones where you turn a knob to the desired temp. 10 degrees isnt a big deal at all when it comes to shower water, but with a brewing system, 10 degrees makes a gigantic difference in your brewing end result. Thats why electronic PID controllers and temp probes in the proper location is the most common setup for brewing as opposed to a rudamentary dial.

At the end of the day, an electric water heater thermostat does the same thing as a full brewerry controller.........it turns an element on and off to achieve a desired temperature.

However while a water heater T-stat might be set to "120", the actual temperature is probably plus or minus 10 degrees if its not an accurate digital Pid controlled thermostat, and is instead one of those ones where you turn a knob to the desired temp. 10 degrees isnt a big deal at all when it comes to shower water, but with a brewing system, 10 degrees makes a gigantic difference in your brewing end result. Thats why electronic PID controllers and temp probes in the proper location is the most common setup for brewing as opposed to a rudamentary dial.

If you were electrically inclined to know how to repurpose a water heater controller onto a brewing kettle safely, you'd also be skilled enough to build a simple PID/SSR based controller as well. The latter is better in many ways and not all that expensive either. A water heater controller would also not have a manual mode that would regulate your boil intensity.

LarMoeCur

Well-Known Member

…an electric water heater thermostat to set the temp of my all-in-one?

I can think of a few reasons to not use them.

First, you said "all in one". So you plan to boil in this vessel. I the highest setting I've ever seen on a hot water heater is 160F. Most of the ones, I've seen are 150F max setting. So mashing you are good but, no mash out or boiling temps.

Second, the temperature setting on a hot water heater is rudimentary at best. It's a little set screw that you will have to set with a screw driver or fashion a knob and attach it. Then you would have to fabricate some kind of protection plate to cover the exposed connections. You can mount it in a box sure but most of the wire connections are on the top of the controller. Clearly very dangerous if not covered correctly. Some have the temp probe coming right out of the back of it to be treaded directly into the tank. So, you would have to mount the controller to your kettle. Not an ideal set up in my mind.

Lastly, Sick said it first. They are not very accurate. Who want's to have to baby sit a their mash checking the temperature and moving a tiny set screw up or down every 10 minutes to hit a mash temp. Bobby said it already. The PID to SSR is exactly the same as what the hot water heater is doing just not with a stone age era control module. They are highly accurate and almost set and forget. They are only a few dollars more then a hot water heater controller but way...way...way better.

I want to thank everyone for their input…being relatively new to the entire brewing “scene”, the level of knowledge you all impart is immensely helpful.I can think of a few reasons to not use them.

First, you said "all in one". So you plan to boil in this vessel. I the highest setting I've ever seen on a hot water heater is 160F. Most of the ones, I've seen are 150F max setting. So mashing you are good but, no mash out or boiling temps.

Second, the temperature setting on a hot water heater is rudimentary at best. It's a little set screw that you will have to set with a screw driver or fashion a knob and attach it. Then you would have to fabricate some kind of protection plate to cover the exposed connections. You can mount it in a box sure but most of the wire connections are on the top of the controller. Clearly very dangerous if not covered correctly. Some have the temp probe coming right out of the back of it to be treaded directly into the tank. So, you would have to mount the controller to your kettle. Not an ideal set up in my mind.

Lastly, Sick said it first. They are not very accurate. Who want's to have to baby sit a their mash checking the temperature and moving a tiny set screw up or down every 10 minutes to hit a mash temp. Bobby said it already. The PID to SSR is exactly the same as what the hot water heater is doing just not with a stone age era control module. They are highly accurate and almost set and forget. They are only a few dollars more then a hot water heater controller but way...way...way better.

I want to convert to electric…in a bad way. However, there are certain budget restrictions that I also have to stick to. I’m trying to do this as inexpensively as possible without being unsafe and still being able to brew indoors.Obviously from this post and my previous posts I want my setup to be an all-in-one system. I’m pretty handy with electronics, wiring, soldering etc (10+ years at the old-school RadioShacks will do that for a person)…but I am not well versed in electrical “theory”. I’m looking for all the direction I can get to help me through until I can save up the $$$ to buy an actual controller.

Who can help me?

$479.00

$559.00

EdgeStar KC1000SS Craft Brew Kegerator for 1/6 Barrel and Cornelius Kegs

Amazon.com

$20.94

$29.99

The Brew Your Own Big Book of Clone Recipes: Featuring 300 Homebrew Recipes from Your Favorite Breweries

Amazon.com

$176.97

1pc Commercial Keg Manifold 2" Tri Clamp,Ball Lock Tapping Head,Pressure Gauge/Adjustable PRV for Kegging,Fermentation Control

hanhanbaihuoxiaoshoudian

$33.99 ($17.00 / Count)

$41.99 ($21.00 / Count)

2 Pack 1 Gallon Large Fermentation Jars with 3 Airlocks and 2 SCREW Lids(100% Airtight Heavy Duty Lid w Silicone) - Wide Mouth Glass Jars w Scale Mark - Pickle Jars for Sauerkraut, Sourdough Starter

Qianfenie Direct

$53.24

1pc Hose Barb/MFL 1.5" Tri Clamp to Ball Lock Post Liquid Gas Homebrew Kegging Fermentation Parts Brewer Hardware SUS304(Liquid Hose Barb)

Guangshui Weilu You Trading Co., Ltd

$58.16

HUIZHUGS Brewing Equipment Keg Ball Lock Faucet 30cm Reinforced Silicone Hose Secondary Fermentation Homebrew Kegging Brewing Equipment

xiangshuizhenzhanglingfengshop

$22.00 ($623.23 / Ounce)

AMZLMPKNTW Ball Lock Sample Faucet 30cm Reinforced Silicone Hose Secondary Fermentation Homebrew Kegging joyful

无为中南商贸有限公司

$53.24

1pc Hose Barb/MFL 1.5" Tri Clamp to Ball Lock Post Liquid Gas Homebrew Kegging Fermentation Parts Brewer Hardware SUS304(Liquid Hose Barb)

yunchengshiyanhuqucuichendianzishangwuyouxiangongsi

$7.79 ($7.79 / Count)

Craft A Brew - LalBrew Voss™ - Kveik Ale Yeast - For Craft Lagers - Ingredients for Home Brewing - Beer Making Supplies - (1 Pack)

Craft a Brew

$719.00

$799.00

EdgeStar KC2000TWIN Full Size Dual Tap Kegerator & Draft Beer Dispenser - Black

Amazon.com

$10.99 ($31.16 / Ounce)

Hornindal Kveik Yeast for Homebrewing - Mead, Cider, Wine, Beer - 10g Packet - Saccharomyces Cerevisiae - Sold by Shadowhive.com

Shadowhive

crazyjake19

Well-Known Member

Do you already have a kettle you can convert? That would save a big chunk of change.

I built my very frugal electric setup about 3 years ago and I'm still using it without any desire to upgrade. It's basically an electric element ($20), AuberIns EZ Boil PID controller ($46), solid state relay ($22), heat sink ($10), RTD temp probe ($27), double pole contactor ($10), and a switch for the contactor ($4). Most of the wire and connectors I already had but would've cost around $15-20. Plus the enclosure for the control box was around $20. So altogether I was in about $160. You could easily scavenge the wire and enclosure, skip the contactor/switch, and be in for around $125.

Assuming you're looking at a 240V setup, you still need to consider a two pole GFCI breaker or spa panel which includes one, and any other wire. These breakers are not cheap, you're looking at $100 on average plus some wire.

Have you considered small batches using a 120V system? You could use an existing GFCI in your kitchen, garage, outdoors, etc and rule out the cost of any home wiring upgrades. You could build a similar controller to what I mentioned above for around $100-120. You could also use a SSVR (solid state voltage regulator) in place of the SSR and PID controller to save a bit more, though you lose the precise temperature control in that method and replace it with a turn knob, more like using your kitchen stove.

I built my very frugal electric setup about 3 years ago and I'm still using it without any desire to upgrade. It's basically an electric element ($20), AuberIns EZ Boil PID controller ($46), solid state relay ($22), heat sink ($10), RTD temp probe ($27), double pole contactor ($10), and a switch for the contactor ($4). Most of the wire and connectors I already had but would've cost around $15-20. Plus the enclosure for the control box was around $20. So altogether I was in about $160. You could easily scavenge the wire and enclosure, skip the contactor/switch, and be in for around $125.

Assuming you're looking at a 240V setup, you still need to consider a two pole GFCI breaker or spa panel which includes one, and any other wire. These breakers are not cheap, you're looking at $100 on average plus some wire.

Have you considered small batches using a 120V system? You could use an existing GFCI in your kitchen, garage, outdoors, etc and rule out the cost of any home wiring upgrades. You could build a similar controller to what I mentioned above for around $100-120. You could also use a SSVR (solid state voltage regulator) in place of the SSR and PID controller to save a bit more, though you lose the precise temperature control in that method and replace it with a turn knob, more like using your kitchen stove.

I do have a kettle…I’m wanting to convert my keggle, so I’m all set there.Do you already have a kettle you can convert? That would save a big chunk of change.

I built my very frugal electric setup about 3 years ago and I'm still using it without any desire to upgrade. It's basically an electric element ($20), AuberIns EZ Boil PID controller ($46), solid state relay ($22), heat sink ($10), RTD temp probe ($27), double pole contactor ($10), and a switch for the contactor ($4). Most of the wire and connectors I already had but would've cost around $15-20. Plus the enclosure for the control box was around $20. So altogether I was in about $160. You could easily scavenge the wire and enclosure, skip the contactor/switch, and be in for around $125.

Assuming you're looking at a 240V setup, you still need to consider a two pole GFCI breaker or spa panel which includes one, and any other wire. These breakers are not cheap, you're looking at $100 on average plus some wire.

Have you considered small batches using a 120V system? You could use an existing GFCI in your kitchen, garage, outdoors, etc and rule out the cost of any home wiring upgrades. You could build a similar controller to what I mentioned above for around $100-120. You could also use a SSVR (solid state voltage regulator) in place of the SSR and PID controller to save a bit more, though you lose the precise temperature control in that method and replace it with a turn knob, more like using your kitchen stove.

I am wanting to run 240v and already have the box and outlet installed, so that’s all set.

I appreciate the list in the first paragraph…that’s the route I want to go. Any other advice or links? I’m already building a shopping cart on Auber, so that’s all set.

I would recommend against eliminating the contactor and switch. SSRs tend to fail in the on mode, and you really want to have a contactor (or high current rated manual switch) to be able to shut of the runaway SSR. SSRs latching in the on mode is not always a permanent failure (just from getting too hot) and shutting them off for a while will reset them. You don't want to pull a plug out of the wall that is carrying 23A of current, and running back to the breaker panel to shut it off can be inconvenient.Do you already have a kettle you can convert? That would save a big chunk of change.

I built my very frugal electric setup about 3 years ago and I'm still using it without any desire to upgrade. It's basically an electric element ($20), AuberIns EZ Boil PID controller ($46), solid state relay ($22), heat sink ($10), RTD temp probe ($27), double pole contactor ($10), and a switch for the contactor ($4). Most of the wire and connectors I already had but would've cost around $15-20. Plus the enclosure for the control box was around $20. So altogether I was in about $160. You could easily scavenge the wire and enclosure, skip the contactor/switch, and be in for around $125.

Assuming you're looking at a 240V setup, you still need to consider a two pole GFCI breaker or spa panel which includes one, and any other wire. These breakers are not cheap, you're looking at $100 on average plus some wire.

Have you considered small batches using a 120V system? You could use an existing GFCI in your kitchen, garage, outdoors, etc and rule out the cost of any home wiring upgrades. You could build a similar controller to what I mentioned above for around $100-120. You could also use a SSVR (solid state voltage regulator) in place of the SSR and PID controller to save a bit more, though you lose the precise temperature control in that method and replace it with a turn knob, more like using your kitchen stove.

Brew on

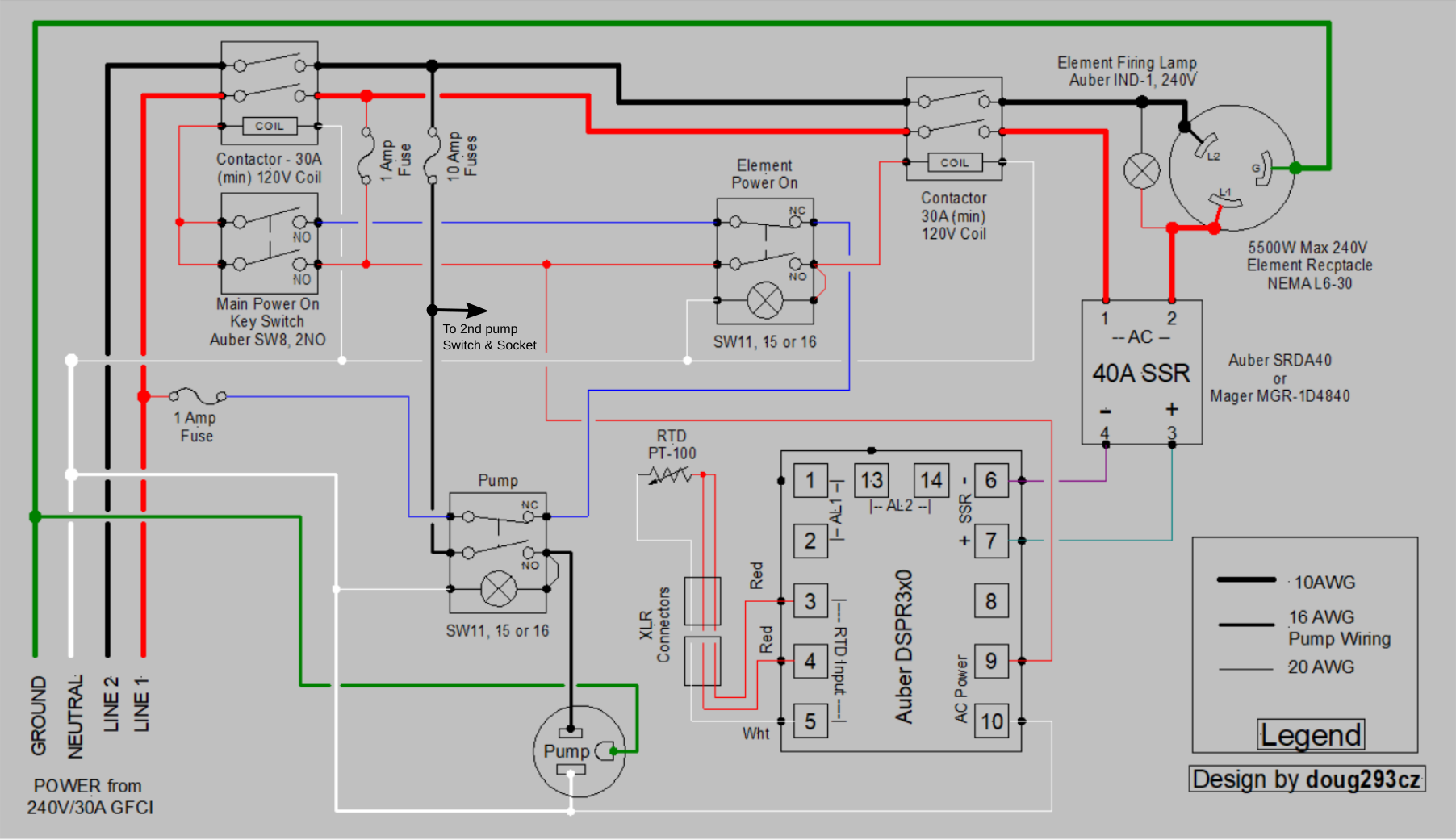

Here's my preferred design for a single vessel controller. You can leave out the pump circuitry if you don't need it. It's also possible to leave out the main power contactor, but then you lose the "safe start" interlock. I can show you how to modify the design if you are interested. This design can use the Auber DSPR120 EZBoil, or any of the 300 series.I do have a kettle…I’m wanting to convert my keggle, so I’m all set there.

I am wanting to run 240v and already have the box and outlet installed, so that’s all set.

I appreciate the list in the first paragraph…that’s the route I want to go. Any other advice or links? I’m already building a shopping cart on Auber, so that’s all set.

Brew on

I want to thank everyone for their input…being relatively new to the entire brewing “scene”, the level of knowledge you all impart is immensely helpful.

I want to convert to electric…in a bad way. However, there are certain budget restrictions that I also have to stick to. I’m trying to do this as inexpensively as possible without being unsafe and still being able to brew indoors.Obviously from this post and my previous posts I want my setup to be an all-in-one system. I’m pretty handy with electronics, wiring, soldering etc (10+ years at the old-school RadioShacks will do that for a person)…but I am not well versed in electrical “theory”. I’m looking for all the direction I can get to help me through until I can save up the $$$ to buy an actual controller.

Who can help me?

I have two of these. One attached to my HLT and one attached to my boil kettle. Both control 5500 watt water heater elements and work like a charm. Been using them for a couple of years. I got mine from EB but this version is identical.

https://amazon.com/Electronic-Regul...att+240+volt+controller&qid=1632139059&sr=8-5

Similar threads

- Replies

- 4

- Views

- 503

- Replies

- 25

- Views

- 986

- Replies

- 12

- Views

- 755

![Craft A Brew - Safale BE-256 Yeast - Fermentis - Belgian Ale Dry Yeast - For Belgian & Strong Ales - Ingredients for Home Brewing - Beer Making Supplies - [3 Pack]](https://m.media-amazon.com/images/I/51bcKEwQmWL._SL500_.jpg)