dunbruha

Well-Known Member

Hi,

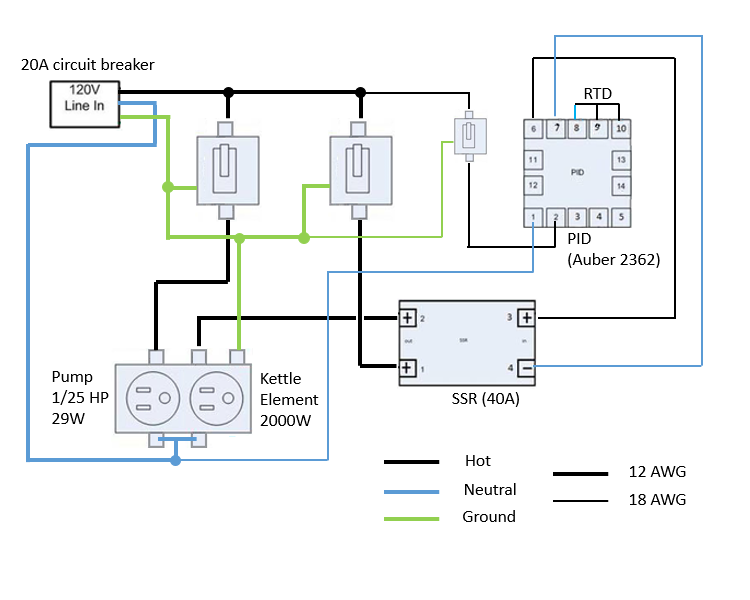

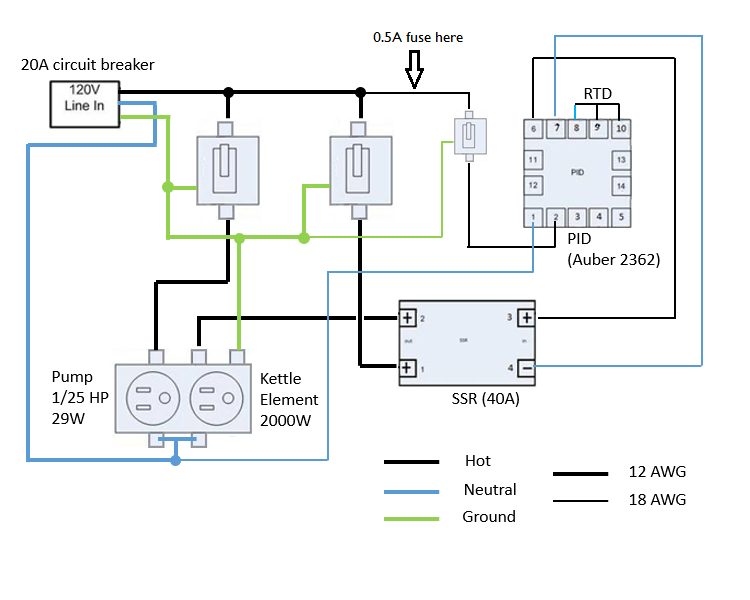

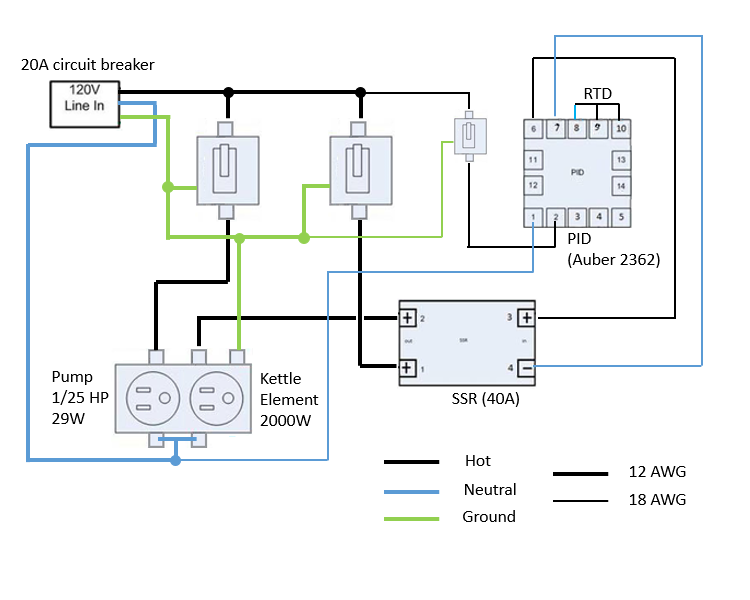

I am almost finished building my electric kettle control panel, and I cant figure out where (or if) I should put a fuse. I am attaching a diagram of my panel. Several posts on this forum suggest putting fuses in various places, but I cant decide which is correct. I emailed Auber, and they said:

For the controller, 250Vac > 0.1 A fast blow fuse could work but probably not necessary. There is a large resistor in the power input module that works like a fuse. The controller normally will only draw small current. If it draws more current than it should, it means something inside has been burnt. In that case, the fuse can not protect the controller. And the issue won't be fix by replacing the fuse. However, if there is a current spike come from outside the controller, then the fuse can protect the controller. But in that situation, the fuse can be placed in close to the power input in your system and so you will need a fuse with higher current rating.

So, any advice on what kind of fuse to use, and where to put it?

I am almost finished building my electric kettle control panel, and I cant figure out where (or if) I should put a fuse. I am attaching a diagram of my panel. Several posts on this forum suggest putting fuses in various places, but I cant decide which is correct. I emailed Auber, and they said:

For the controller, 250Vac > 0.1 A fast blow fuse could work but probably not necessary. There is a large resistor in the power input module that works like a fuse. The controller normally will only draw small current. If it draws more current than it should, it means something inside has been burnt. In that case, the fuse can not protect the controller. And the issue won't be fix by replacing the fuse. However, if there is a current spike come from outside the controller, then the fuse can protect the controller. But in that situation, the fuse can be placed in close to the power input in your system and so you will need a fuse with higher current rating.

So, any advice on what kind of fuse to use, and where to put it?