Sometimes you win, sometimes you learn. Today is the latter. So help from the community is appreciated.

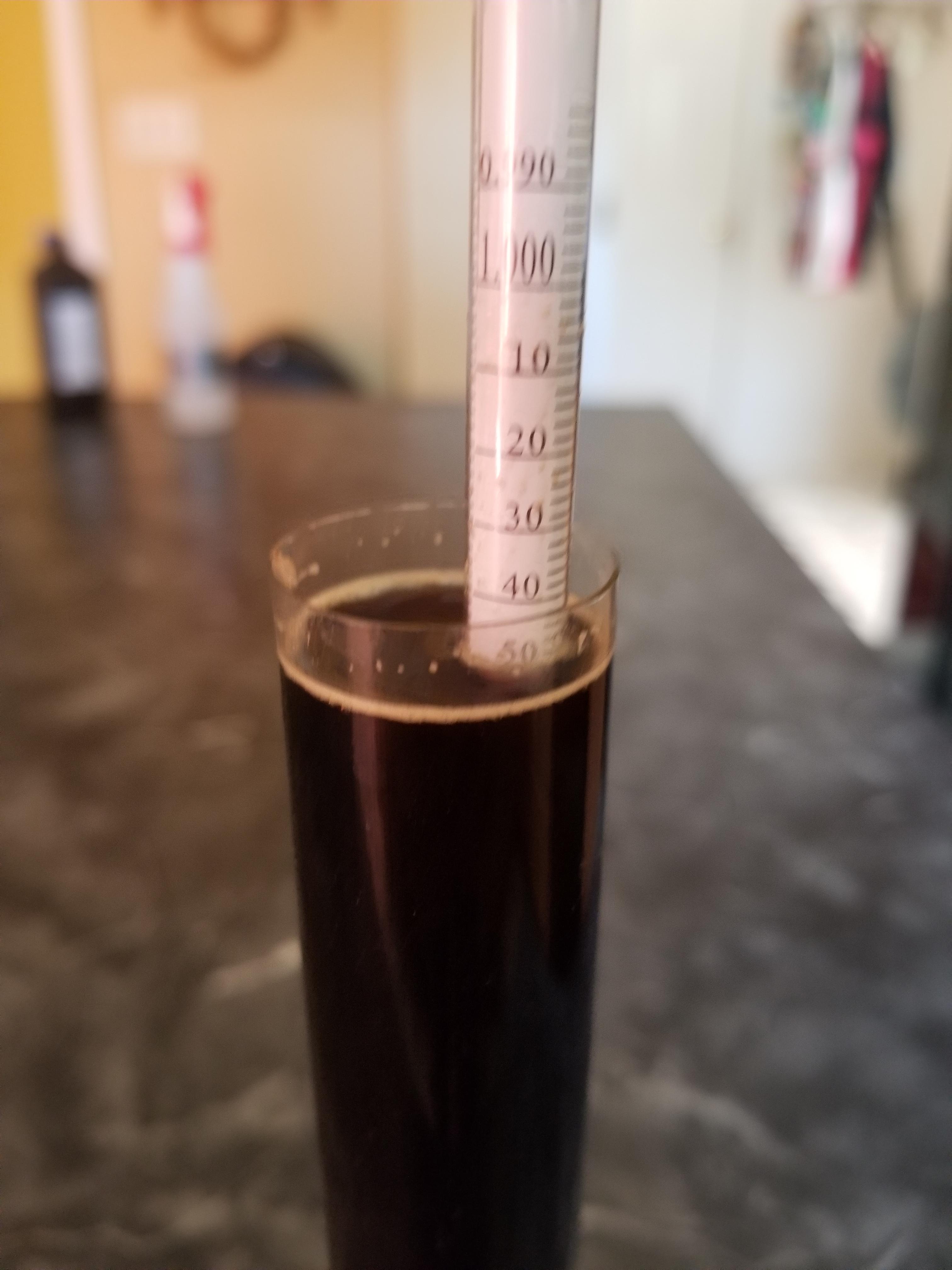

In making my wet hop saison, I had a giant bag of whole cones in the wort, so that they wouldn't plug the wort chiller, which I used for the very first time. I thought I would be smart and I put my immersion chiller in ice water, the water at about 40F then heading to the plate chiller. However, in running the wort out through the plate chiller into the fermenter, it came out at about 140F. And all of the break material ran out with the wort. I have subsequently chilled the wort to 80F, aerated with O2, and pitched the saison yeast starter.

When I have chilled with the immersion chiller in the wort, I have been able to run it into the fermenter at 80F or less, and the break material goes through a fine-screen chinois which catches the material and hops, and then also aerates the wort at the same time.

So, what should I have done differently with the plate chiller in order to get similar results?

In making my wet hop saison, I had a giant bag of whole cones in the wort, so that they wouldn't plug the wort chiller, which I used for the very first time. I thought I would be smart and I put my immersion chiller in ice water, the water at about 40F then heading to the plate chiller. However, in running the wort out through the plate chiller into the fermenter, it came out at about 140F. And all of the break material ran out with the wort. I have subsequently chilled the wort to 80F, aerated with O2, and pitched the saison yeast starter.

When I have chilled with the immersion chiller in the wort, I have been able to run it into the fermenter at 80F or less, and the break material goes through a fine-screen chinois which catches the material and hops, and then also aerates the wort at the same time.

So, what should I have done differently with the plate chiller in order to get similar results?

![Craft A Brew - Safale BE-256 Yeast - Fermentis - Belgian Ale Dry Yeast - For Belgian & Strong Ales - Ingredients for Home Brewing - Beer Making Supplies - [3 Pack]](https://m.media-amazon.com/images/I/51bcKEwQmWL._SL500_.jpg)