I decided I needed a break from telecommuting so at lunch Wednesday I decided to brew up a small 2.5 gal batch of Amber. Used one ounce of Cascade pellets and 1.25 oz of homegrown Willamette. Sample tasted smooth. Now to wait.

If I cold crash in 1 gallon jugs like that, will I be able to bottle? Are you force carbonating into kegs?View attachment 673845

My freezer is full of carbonating kegs, so I had to cold crash the next batch in 1 gallon water bottles. Did a little online shopping last night for another 7 cu ft chest freezer, nobody within 100 miles has one in stock.

Yes, you could still bottle, there is not much chance all the yeast will settle out. It kind of depends on the carbonation level you're looking for. I'm usually making Belgian tripels and pales, and looking for 3-3.5 volumes of CO2. In that case, I make a guesstimate of remaining yeast viability, and may decide to add fresh yeast (CBC-1) and priming sugar before bottling.If I cold crash in 1 gallon jugs like that, will I be able to bottle? Are you force carbonating into kegs?

That sounds pretty nice. What was OG,?BTW, I decanted 6 gallons back into fermenter a little while ago. I'm going to let it warm up overnight, and pitch a fresh batch of temperature resistant yeast tomorrow.

This is a tripel, experimenting with Neo-1 hops. Arrested first fermentation at 1.020 gravity.

That sounds pretty nice. What was OG,?

I have a batch stuck at 1.020, but the half of it I've bottled worked out. Would you recommend adding priming sugar and pitching more yeast? I am probably going to bottle in 1 lt Seltzer bottles due to lack of glass bottles.

Originally 5 gallons, but I bottled 2.25 gallons. Probably about 2.5 gallons left minus sediment.OG was 1.085. I can't work with the info provided. How much beer are we talking about? What is the FG now, and what is the target FG? What style of beer? How long has it been fermenting and at what temp? What yeast are you using?

View attachment 674506

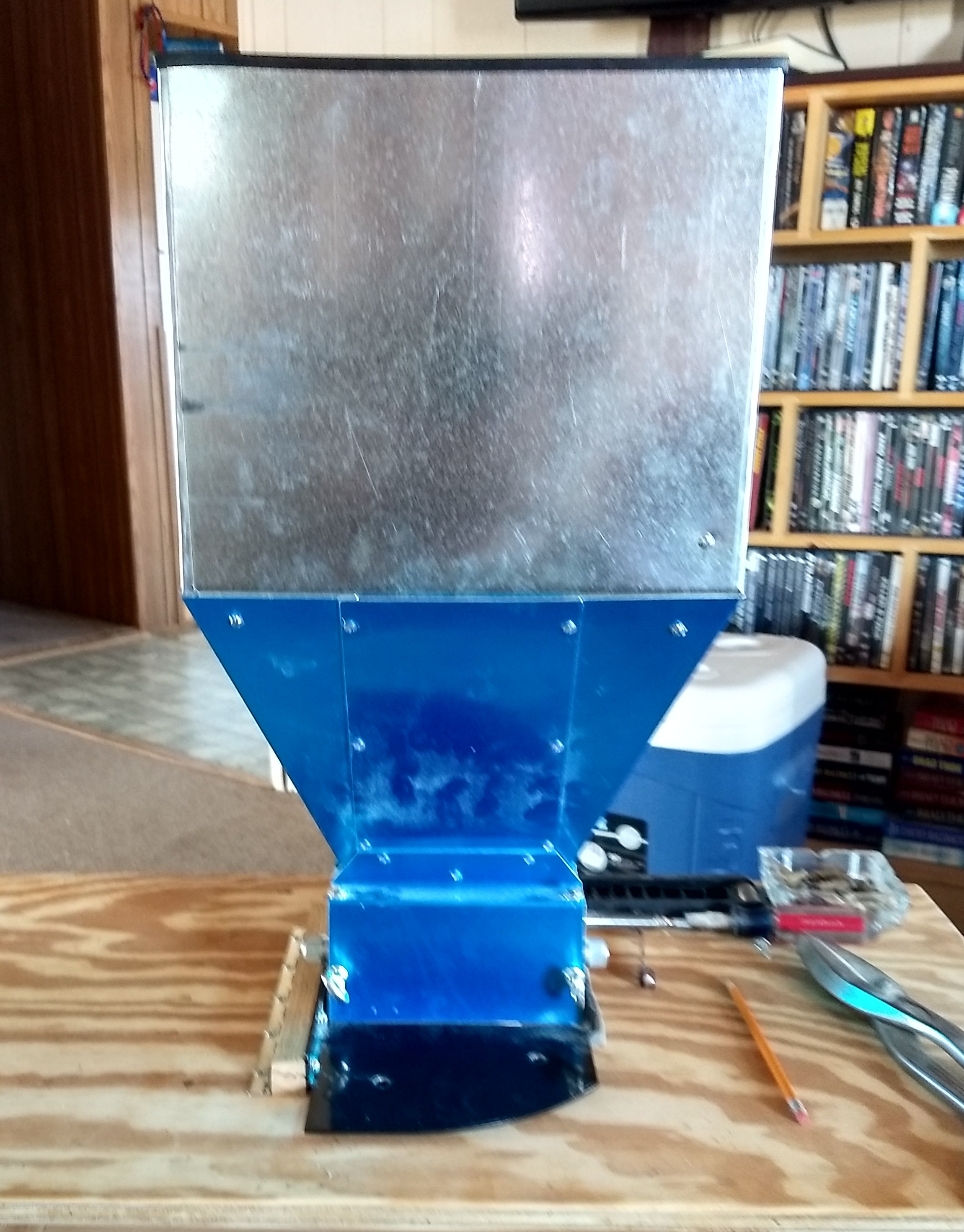

Fabricating a hopper extension for my mill. Didn't get enough screws, another Home Depot run in a few.

Yesterday I built a rolling cabinet for the mill, @mongoose33 's suggestion, I used a Harbor Freight furniture dolly for the base. Since I was planning the hopper extension, I wanted to use something other than a 5 gallon bucket....

View attachment 674508

so, I found this 105 qt storage bin at wallyworld for 8 bucks. So far, I'm into it for 8 bucks, plus about 30 bucks for the sheet metal and hardware. Next project is cutting the hole in the top, and I'm planning on hinging the mill so it can be swung open from the base for inspection or maintenance.

What the hell did you brewI got you all beat, i did a two day brew! started at 8pm 4-5-20, finish at 4-6-20 at 5:30am a minute ago....(got 90% efficiency on it too, yea!)

I think 40° might be a bit low. Try 48° F.View attachment 674532Pitched 2 pks Saf 34/70 into the Helles after cold crashing 2 days to 40°. 6 weeks till my first kegging ever!

Mine is set up that way as well. One word of warning: be careful as to how much you open that lid without being able to secure it. On mine, with the heavy All American Aleworks motor plus the mill, if I open it too far, the cart will go all squiggly on me. I have a wooden stick I use to prop it open at a height where things don't go wonky.

View attachment 674521