Today I bottled my Leffe Blonde clone at 7.1% into 36 50cl bottles.

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

What I did for beer today

- Thread starter iaefebs

- Start date

Help Support Homebrew Talk:

This site may earn a commission from merchant affiliate

links, including eBay, Amazon, and others.

I took leap to brew NA beer. LHBS had WLP618 brewing yeast, Saccharomycodes ludwigii so I got a packet. I used the White Labs recipe; 2# pale, 4oz each of white wheat, flaked oaks & carafoam. 1.5 oz each of Citra & Mossaic. Mash 169f!! Smells like beer, very pale, so we’ll see in a couple weeks.

Went and visited the LHBS today. Finally going to try and do a golden stout!!

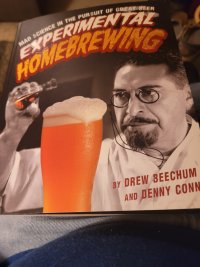

I’ve had this book marked for over 2 years. Have the recipe in brewersfriend already so, sometime this week it is happening!

https://beohhasbrewhouse.com/2021/06/27/brewing-a-golden-oatmeal-stout/

I’ve had this book marked for over 2 years. Have the recipe in brewersfriend already so, sometime this week it is happening!

https://beohhasbrewhouse.com/2021/06/27/brewing-a-golden-oatmeal-stout/

Last time I tried to hit Piraat numbers, it finished out at 14% instead of 9. But that was an extract brew with adjuncts. This time it would be all grain. And sugar.View attachment 865476

I loves me some Piraat. Tried to clone it once, it was OK. Might have to take another shot at it. If you brew it, let us know how it goes.

- Joined

- Jan 3, 2020

- Messages

- 3,227

- Reaction score

- 3,910

Passivated my new unitank and mini brew bucket. Might go downstairs and put the fittings on the uni in a bit...

$33.99 ($17.00 / Count)

$41.99 ($21.00 / Count)

2 Pack 1 Gallon Large Fermentation Jars with 3 Airlocks and 2 SCREW Lids(100% Airtight Heavy Duty Lid w Silicone) - Wide Mouth Glass Jars w Scale Mark - Pickle Jars for Sauerkraut, Sourdough Starter

Qianfenie Direct

$7.79 ($7.79 / Count)

Craft A Brew - LalBrew Voss™ - Kveik Ale Yeast - For Craft Lagers - Ingredients for Home Brewing - Beer Making Supplies - (1 Pack)

Craft a Brew

$53.24

1pc Hose Barb/MFL 1.5" Tri Clamp to Ball Lock Post Liquid Gas Homebrew Kegging Fermentation Parts Brewer Hardware SUS304(Liquid Hose Barb)

Guangshui Weilu You Trading Co., Ltd

$176.97

1pc Commercial Keg Manifold 2" Tri Clamp,Ball Lock Tapping Head,Pressure Gauge/Adjustable PRV for Kegging,Fermentation Control

hanhanbaihuoxiaoshoudian

$76.92 ($2,179.04 / Ounce)

Brewing accessories 1.5" Tri Clamp to Ball Lock Post Liquid Gas Homebrew Kegging Fermentation Parts Brewer Hardware SUS304 Brewing accessories(Gas Hose Barb)

chuhanhandianzishangwu

$22.00 ($623.23 / Ounce)

AMZLMPKNTW Ball Lock Sample Faucet 30cm Reinforced Silicone Hose Secondary Fermentation Homebrew Kegging joyful

无为中南商贸有限公司

$28.98

Five Star - 6022b_ - Star San - 32 Ounce - High Foaming Sanitizer

Great Fermentations of Indiana

$44.99

$49.95

Craft A Brew - Mead Making Kit – Reusable Make Your Own Mead Kit – Yields 1 Gallon of Mead

Craft a Brew

$719.00

$799.00

EdgeStar KC2000TWIN Full Size Dual Tap Kegerator & Draft Beer Dispenser - Black

Amazon.com

$53.24

1pc Hose Barb/MFL 1.5" Tri Clamp to Ball Lock Post Liquid Gas Homebrew Kegging Fermentation Parts Brewer Hardware SUS304(Liquid Hose Barb)

yunchengshiyanhuqucuichendianzishangwuyouxiangongsi

$159.50 ($26.58 / Count)

3M High Flow Series System BREW120-MS, 5616001, For Brewed Coffee and Hot Tea, Valve-in-Head Design

Amazon.com

$10.99 ($31.16 / Ounce)

Hornindal Kveik Yeast for Homebrewing - Mead, Cider, Wine, Beer - 10g Packet - Saccharomyces Cerevisiae - Sold by Shadowhive.com

Shadowhive

$479.00

$559.00

EdgeStar KC1000SS Craft Brew Kegerator for 1/6 Barrel and Cornelius Kegs

Amazon.com

$58.16

HUIZHUGS Brewing Equipment Keg Ball Lock Faucet 30cm Reinforced Silicone Hose Secondary Fermentation Homebrew Kegging Brewing Equipment

xiangshuizhenzhanglingfengshop

$20.94

$29.99

The Brew Your Own Big Book of Clone Recipes: Featuring 300 Homebrew Recipes from Your Favorite Breweries

Amazon.com

- Joined

- Jan 23, 2021

- Messages

- 352

- Reaction score

- 2,264

Filled 2 kegs with Russian River STS clone, brewed December 10th. I used the recipe recently published in BYO.

I also cleaned 4 kegs.

I also cleaned 4 kegs.

Busy day today, made my R/O/DI water for fridays brew, added my "brewing salts" checked the ph,and retained 4.25 gallons for strike water putting the balance of 6,5 gallons in my hot liquor tank.

Installed my digital read out I got the other day, then crushed my grain for Fridays brew day.

Moved my burbon aged ale to the secondary and added the burbon/oak chip tincture,this way I dont tie up my fermenter for a month.

My secondary is heated by the blue button pad, cooled by the brew styx controled by an inkbird controler..the insulated "box"keeps the brew away from daylight and is on casters.

Installed my digital read out I got the other day, then crushed my grain for Fridays brew day.

Moved my burbon aged ale to the secondary and added the burbon/oak chip tincture,this way I dont tie up my fermenter for a month.

My secondary is heated by the blue button pad, cooled by the brew styx controled by an inkbird controler..the insulated "box"keeps the brew away from daylight and is on casters.

Attachments

- Joined

- Sep 6, 2021

- Messages

- 583

- Reaction score

- 2,515

As both fermenters are in use now, I spent the day cleaning a backlog of bottles soaking to remove labels etc.

Brewed my first beer of the year!

Treehouse style IPA with CGX Azacca, Moutere and Nectaron. 7.5% with a target FG of 1.019, 42 IBU and a planned 12g/L dry hop. Using up the last of my Lallemand Koln.

Treehouse style IPA with CGX Azacca, Moutere and Nectaron. 7.5% with a target FG of 1.019, 42 IBU and a planned 12g/L dry hop. Using up the last of my Lallemand Koln.

I recently had a couple bad batches of "cidery tasting" beer that could be diagnosed as "yeast stressed" or maybe infection induced off flavors. I tightend up my hygiene to remove any "potential/hidden FV biofilms" on the cold side, and oxygenated my wort for the first time using the anvil wand. Prior to that I always stirred agressively w/ paddle and generally had no other fermentation issues. That said, I also never rehydrated yeast but with my research on "yeast stress" have wondered if I ought to consider that as a mitigating variable also. Likewise, this has me wondering about my ptich rate? Typically I pitch 2 packets (11.5 gm) for my 5 gallon batches as the OG is often between 1.060 and 1.065, and perhaps up to 1.068, based on the "pro brewer" pitch rate. My most recent brew (a club brew) had an OG of 1.054 with the pitch rate specified to mfg recomendation. Our kit included a single 11.5 gm pack of S-04 which I sprinkled dry following oxygenation. So far everything seems to be fermenting nicely and I am hopeful the off flavor beer is behind me. A couple of questions: (1) Is the "pro brewer" pitch rate over the top, or could I get by with mfr recommendation, or mfr + 0.5? (these are brewer's friend options), and (2) is yeast rehydration, necessary or "nice to do"? Although pricey, 1 vs 2 packs of yeast is not a big deal relative to having a pitch rate that will encourage a high probability of healthy fermentation and good beer.I bottled 5.5 gals of ordinary bitter that I brewed earlier this month. It was a "test" to see how it would turn out if I did no oxygenation other than pouring the chilled wort through a stainless strainer into the Brew Bucket. I pitched 1 packet rehydrated S-04 (with an exp. date of May 2024). I do use Go-Ferm when rehydrating. Of course it was a low-gravity beer so I didn't expect the yeast to have a difficult time. Still, it makes me think adding O2 at the pitch isn't necessary for dry yeast. At least not in lower gravity brews. For bigger beers I will hit the wort with O2.

Thanks for the comments and feedback.

You could try adding one variable next time. If you were using O2 but not rehydrating your dry yeast, try rehydrating plus the O2.I recently had a couple bad batches of "cidery tasting" beer that could be diagnosed as "yeast stressed" or maybe infection induced off flavors. I tightend up my hygiene to remove any "potential/hidden FV biofilms" on the cold side, and oxygenated my wort for the first time using the anvil wand. Prior to that I always stirred agressively w/ paddle and generally had no other fermentation issues. That said, I also never rehydrated yeast but with my research on "yeast stress" have wondered if I ought to consider that as a mitigating variable also. Likewise, this has me wondering about my ptich rate? Typically I pitch 2 packets (11.5 gm) for my 5 gallon batches as the OG is often between 1.060 and 1.065, and perhaps up to 1.068, based on the "pro brewer" pitch rate. My most recent brew (a club brew) had an OG of 1.054 with the pitch rate specified to mfg recomendation. Our kit included a single 11.5 gm pack of S-04 which I sprinkled dry following oxygenation. So far everything seems to be fermenting nicely and I am hopeful the off flavor beer is behind me. A couple of questions: (1) Is the "pro brewer" pitch rate over the top, or could I get by with mfr recommendation, or mfr + 0.5? (these are brewer's friend options), and (2) is yeast rehydration, necessary or "nice to do"? Although pricey, 1 vs 2 packs of yeast is not a big deal relative to having a pitch rate that will encourage a high probability of healthy fermentation and good beer.

Thanks for the comments and feedback.

I don't know if the pro brewer pitch rates are critical. I brew almost exclusively with dry yeast, and pitch one packet for 5 gallons of low-med gravity ale worts; 2 packets for lagers and high-gravity ales. It's been a long time since I've experienced stressed yeast types of off-flavors.

I rehydrate, but recently stopped oxygenating for low/med gravity wort--just pouring wort through a mesh colander into the FV. Jury's still out on that, though I just bottled the first "no-extra O2" brew and the sample tasted and smelled fine.

This is also my approach. I don't rehydrate or build starters, just lob it straight in, no oxygenation other than splashing during transfer. 1 pack per 6.5 gal batch under 1.050, 2 for lagers or up to about 1.080 and three device there.I don't know if the pro brewer pitch rates are critical. I brew almost exclusively with dry yeast, and pitch one packet for 5 gallons of low-med gravity ale worts; 2 packets for lagers and high-gravity ales. It's been a long time since I've experienced stressed yeast types of off-flavors.

Three packs of even expensive fancy dry yeast is still cheaper than one smack pack of liquid stuff.

Yesterday I brewed a Irish dry stout, got excellent efficiency and ended up with more beer and a few points higher gravity so it in the nowhere land between a dry stout and an extra stout. It was a 3gal batch to be fermented in a miniSSbucket so I left about a quart in the kettle to provide some headroom.

Today I woke up to find out I needed more headroom, looked to have just started sending krausen thru the airlock so I added blowoff tube.

Also brewed a west coast IPA on the 31st.

Today I woke up to find out I needed more headroom, looked to have just started sending krausen thru the airlock so I added blowoff tube.

Also brewed a west coast IPA on the 31st.

Thanks for the prompt reply. The current 2 brews in progress were oxygentated wort w/ dry yeast. As you suggest if these turn out well, I may opt for rehydrating yeast on the next go around. Every brew is an experiment and hypothesis to test against the null.You could try adding one variable next time. If you were using O2 but not rehydrating your dry yeast, try rehydrating plus the O2.

I don't know if the pro brewer pitch rates are critical. I brew almost exclusively with dry yeast, and pitch one packet for 5 gallons of low-med gravity ale worts; 2 packets for lagers and high-gravity ales. It's been a long time since I've experienced stressed yeast types of off-flavors.

I rehydrate, but recently stopped oxygenating for low/med gravity wort--just pouring wort through a mesh colander into the FV. Jury's still out on that, though I just bottled the first "no-extra O2" brew and the sample tasted and smelled fine.

I have done that before also. Clearly, filling it and leaving the 1/2 gallon is not space enough. I might even argue that filling my 7.5 gallon to 5.5 can be a bit risky too. Good luck. I am sure it will be fine after the clean up.Yesterday I brewed a Irish dry stout, got excellent efficiency and ended up with more beer and a few points higher gravity so it in the nowhere land between a dry stout and an extra stout. It was a 3gal batch to be fermented in a miniSSbucket so I left about a quart in the kettle to provide some headroom.

Today I woke up to find out I needed more headroom, looked to have just started sending krausen thru the airlock so I added blowoff tube.

Also brewed a west coast IPA on the 31st.

Cleaned the fementer and changed the o-rings on the aseptic valve. Getting ready for brew day on Saturday.

John

John

In my experience, cidery flavors occur when I use too much adjunct sweetener, as in 3 lbs of honey in a 5 gallon batch. What did your recipes look like?I recently had a couple bad batches of "cidery tasting" beer that could be diagnosed as "yeast stressed" or maybe infection induced off flavors. I tightend up my hygiene to remove any "potential/hidden FV biofilms" on the cold side, and oxygenated my wort for the first time using the anvil wand. Prior to that I always stirred agressively w/ paddle and generally had no other fermentation issues. That said, I also never rehydrated yeast but with my research on "yeast stress" have wondered if I ought to consider that as a mitigating variable also. Likewise, this has me wondering about my ptich rate? Typically I pitch 2 packets (11.5 gm) for my 5 gallon batches as the OG is often between 1.060 and 1.065, and perhaps up to 1.068, based on the "pro brewer" pitch rate. My most recent brew (a club brew) had an OG of 1.054 with the pitch rate specified to mfg recomendation. Our kit included a single 11.5 gm pack of S-04 which I sprinkled dry following oxygenation. So far everything seems to be fermenting nicely and I am hopeful the off flavor beer is behind me. A couple of questions: (1) Is the "pro brewer" pitch rate over the top, or could I get by with mfr recommendation, or mfr + 0.5? (these are brewer's friend options), and (2) is yeast rehydration, necessary or "nice to do"? Although pricey, 1 vs 2 packs of yeast is not a big deal relative to having a pitch rate that will encourage a high probability of healthy fermentation and good beer.

Thanks for the comments and feedback.

My experiences with straining wort into the fermenter have been positive -- helps keep the trub layer smaller, too.just pouring wort through a mesh colander into the FV. Jury's still out on that, though

Today I bottled 2.5 gallons of belgian quad (1092 -> 1010). Sample tasted really nice! Hoping that I don't end up regretting not adding bottling yeast, but I think Lalbrew Abbaye dry yeast can eat up the priming sugar.

Then I washed, sanitized, and put away 96 bottles.

Then I washed, sanitized, and put away 96 bottles.

Sampled the lager since gravity needle had stopped moving for 2 days. Wasn’t certain it was going to be worth moving forward at only 71’ish% attenuation but it seemed dry enough and thankfully not sweet. So, decided to dry hop it as planned. I’ll transfer in 3 days, let it sit for a couple weeks in the kegerator and try my damndest to ignore it.

- Joined

- Sep 6, 2021

- Messages

- 583

- Reaction score

- 2,515

Kegged an amber ale that has sat in my fermenter in the basement since October 4th. (yesterday)

Brewing an amber lager that hopefully will see a keg sooner than that (today)

Really hoping to get back into the swing of brewing in 2025. Ive missed it quite a bit but finding time and energy has been a chore.

Brewing an amber lager that hopefully will see a keg sooner than that (today)

Really hoping to get back into the swing of brewing in 2025. Ive missed it quite a bit but finding time and energy has been a chore.

Dry hopped my IPA today, removed the blowoff tube from my Irish stout. Lost about a cup of beer but was surprised at the amount of yeast that on the bottom(it's a quart jar).

Also made a 10mL starter from a slant to build up to reslant and make a future beer.

Also made a 10mL starter from a slant to build up to reslant and make a future beer.

BrewMan13

Whole Nother Level Brewing

Racked my gruit stout to the barrel. Decided to condition the barrel with gin in hopes the botanicals with play together with the stuff in the beer. Fingers crossed...

Cleaned all the kegs that kicked over the holidays so they're ready for upcoming brews.

Had a keg kick last night so today I swapped in a freshie and ran the kick through the ol' Mark II.

Then I spent a couple of hours cleaning and sanitizing my RO system before replacing the pre- and post-filters.

Removed all the filter housings and their O-rings for a good cleaning while the membrane rested in a bucket of freshly pulled RO water. Hit the O-rings with silicone keg lube.

Put the empty housings in place then ran 200 ppm bleach sanitizer through the system with a 40 minute dwell time, followed by four rinse cycles. Then I drained the system, installed the new filters, then ran the system to discard a couple of gallons to flush out the filters.

Should be all set for another year

Cheers!

Then I spent a couple of hours cleaning and sanitizing my RO system before replacing the pre- and post-filters.

Removed all the filter housings and their O-rings for a good cleaning while the membrane rested in a bucket of freshly pulled RO water. Hit the O-rings with silicone keg lube.

Put the empty housings in place then ran 200 ppm bleach sanitizer through the system with a 40 minute dwell time, followed by four rinse cycles. Then I drained the system, installed the new filters, then ran the system to discard a couple of gallons to flush out the filters.

Should be all set for another year

Cheers!

Brewed 2.75 gallons (was aiming for 3.0) of basic IPA with Cascade @60, Cascade @10, and Mandarina tossed in once temp cooled to 170 (and left in the kettle to slow-chill outside). Just moved the bucket down to the basement and added yeast (US-05). Got plans for this eventual yeastcake!

Really wish I would have been more careful measuring my strike water, because I was about 1/3 gallon too much. Decided to boil a 3/4 gallon really vigorously on the side until it looked about right, then combined everything. Post boil gravity was 1.062, and volume 2.75 gallons -- software says if I topped that up to 3.0 gallons it'd be right at 1.057 (which the recipe predicted), but I think I'm just going to leave it alone.

Really wish I would have been more careful measuring my strike water, because I was about 1/3 gallon too much. Decided to boil a 3/4 gallon really vigorously on the side until it looked about right, then combined everything. Post boil gravity was 1.062, and volume 2.75 gallons -- software says if I topped that up to 3.0 gallons it'd be right at 1.057 (which the recipe predicted), but I think I'm just going to leave it alone.

Transferred lager from fermenter to keg, which prompted running sanitizer through the keg line before hooking it up to condition in the kegerator.

Which means I have all 4 lines fully populated now! This has only happened maybe three times in the 3ish years I’ve had this damn thing.

Cleaned the lines and connectors used for the transfer, and then looked at the fermenter (a 6.5 Torpedo keg) and asked myself if I felt like cleaning it tonite. Which would require going out in the dark and inspecting the various vermipost bins to determine which I could dump the trub into.

It is still sitting up on the counter where I left it.

Which means I have all 4 lines fully populated now! This has only happened maybe three times in the 3ish years I’ve had this damn thing.

Cleaned the lines and connectors used for the transfer, and then looked at the fermenter (a 6.5 Torpedo keg) and asked myself if I felt like cleaning it tonite. Which would require going out in the dark and inspecting the various vermipost bins to determine which I could dump the trub into.

It is still sitting up on the counter where I left it.

Similar threads

- Replies

- 66

- Views

- 2K

- Replies

- 20

- Views

- 1K

- Replies

- 55

- Views

- 2K

![Craft A Brew - Safale BE-256 Yeast - Fermentis - Belgian Ale Dry Yeast - For Belgian & Strong Ales - Ingredients for Home Brewing - Beer Making Supplies - [3 Pack]](https://m.media-amazon.com/images/I/51bcKEwQmWL._SL500_.jpg)