- Joined

- Mar 30, 2018

- Messages

- 63

- Reaction score

- 39

I got midway through my most recent brew day on my Kal-clone system and heard a "pop" and everything shut down. Upon investigation, I found that my boil kettle SSR blew apart and tripped the circuit breaker. Since I saw nothing wrong elsewhere and have been using this system successfully for a while with no changes I thought the SSR was maybe bad and swapped it out for a spare. About 5 minutes after firing it back up I heard a similar pop and found a similarly fried SSR.

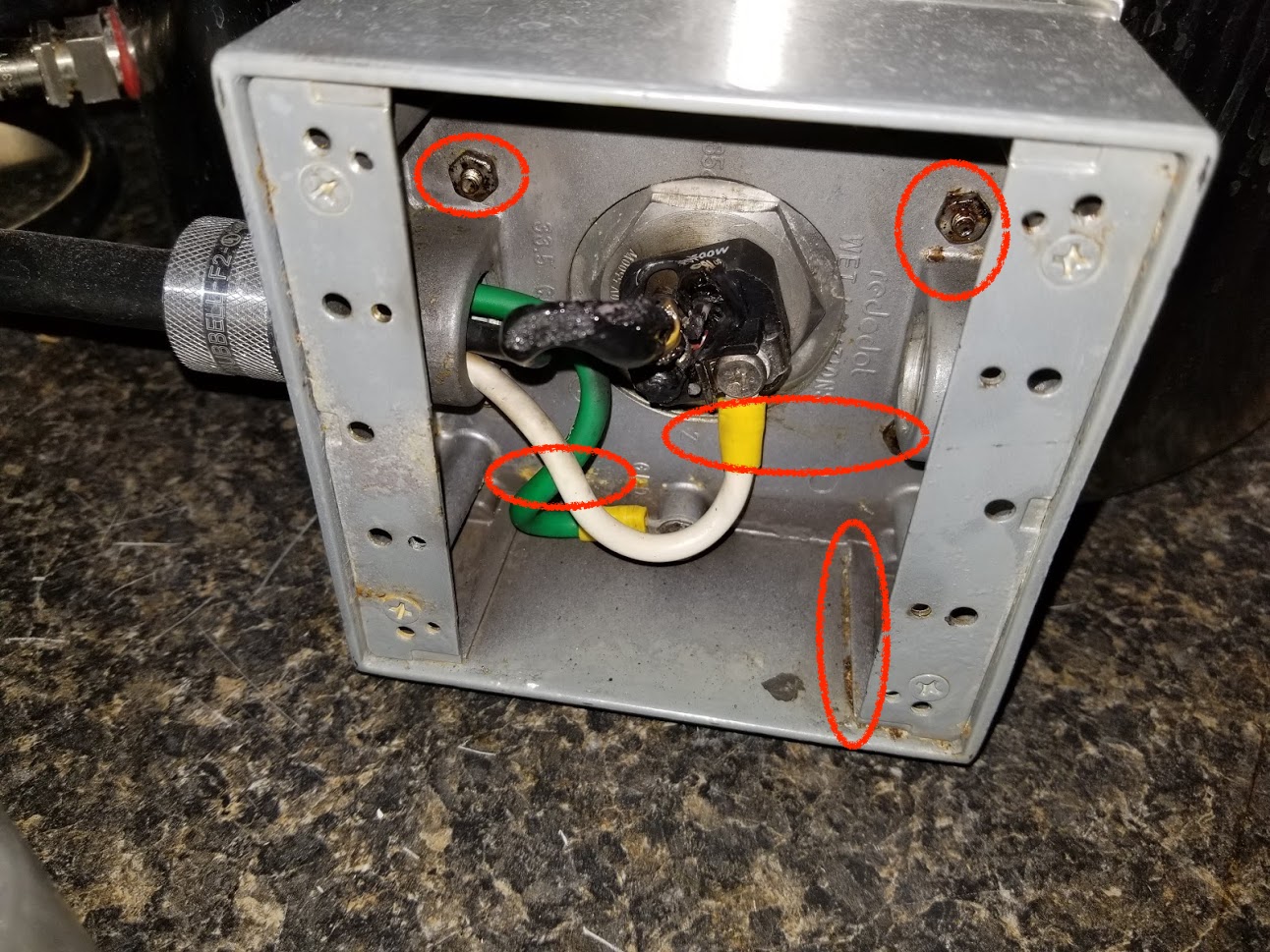

I checked inside the element connection box and found the reason the SSR was blowing.

I have a spare element (new vs. old comparison):

And I can replace the wire connections but I'm curious if anyone can offer any insight on what actually went wrong here. Obviously there was a short that fried the element and the black wire but I'm not sure why or which one came first? Does anyone see anything that would point to one of these?

Bad element?

Poor connection on ring terminal to element?

Poor connection on ring terminal crimp?

Something else?

I'm pretty sure the connections were good but not ruling anything out at this point.

P.S. If anyone has any recommendations on replacement SSRs let me know. I'm hoping to avoid amazon due to their problem with counterfeits but might have to go that way anyway.

I checked inside the element connection box and found the reason the SSR was blowing.

I have a spare element (new vs. old comparison):

And I can replace the wire connections but I'm curious if anyone can offer any insight on what actually went wrong here. Obviously there was a short that fried the element and the black wire but I'm not sure why or which one came first? Does anyone see anything that would point to one of these?

Bad element?

Poor connection on ring terminal to element?

Poor connection on ring terminal crimp?

Something else?

I'm pretty sure the connections were good but not ruling anything out at this point.

P.S. If anyone has any recommendations on replacement SSRs let me know. I'm hoping to avoid amazon due to their problem with counterfeits but might have to go that way anyway.

![Craft A Brew - Safale BE-256 Yeast - Fermentis - Belgian Ale Dry Yeast - For Belgian & Strong Ales - Ingredients for Home Brewing - Beer Making Supplies - [3 Pack]](https://m.media-amazon.com/images/I/51bcKEwQmWL._SL500_.jpg)