rubiconbrewer

Well-Known Member

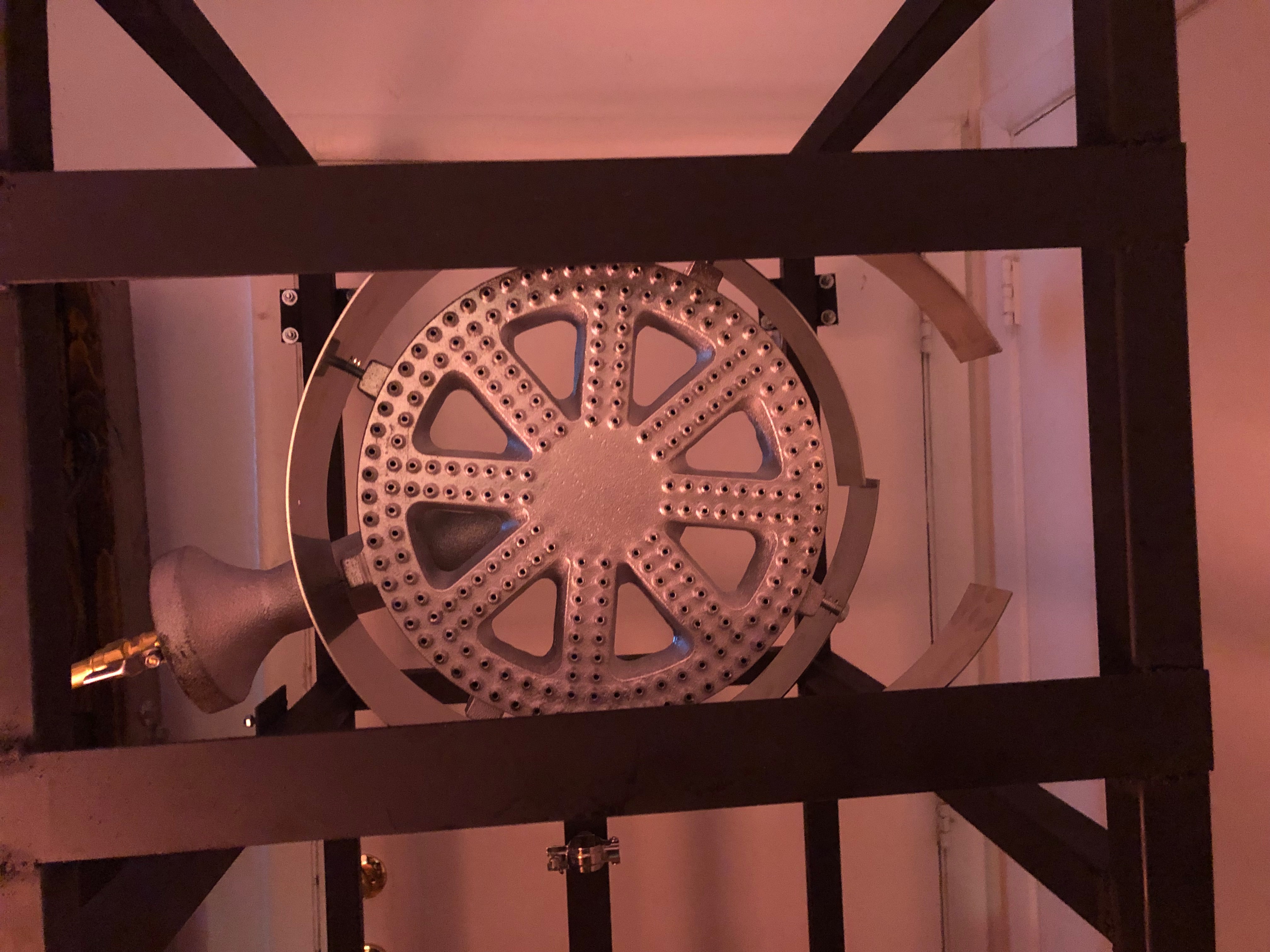

Thanks Day tripper for posting your drawing and thanks to Socal for sharing your dimensions. Fusa your brewstand is coming along great, thanks for posting the pic.

I have my tubing ordered so I'm hopping to start building it in the next couple weekends.

Where did you guys get your casters from? That is one thing I still have yet to figure out.

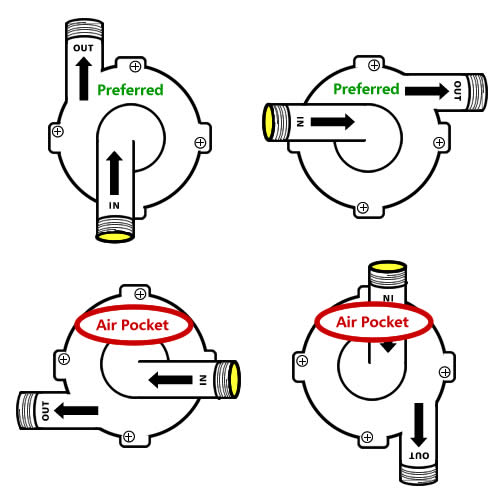

Also, does anyone have any tips on pump placement?

I have my tubing ordered so I'm hopping to start building it in the next couple weekends.

Where did you guys get your casters from? That is one thing I still have yet to figure out.

Also, does anyone have any tips on pump placement?

![Craft A Brew - Safale S-04 Dry Yeast - Fermentis - English Ale Dry Yeast - For English and American Ales and Hard Apple Ciders - Ingredients for Home Brewing - Beer Making Supplies - [1 Pack]](https://m.media-amazon.com/images/I/41fVGNh6JfL._SL500_.jpg)