brewbama

Well-Known Member

- Joined

- Sep 20, 2013

- Messages

- 3,802

- Reaction score

- 2,829

No, unfortunately. He also has something on his website about vacation in early August, so I suspect it's a couple weeks at the earliest. I'm also going to do the steam condenser he's got coming, but that's supposed to be in relatively soon.

I'm putting an element in my 10-gallon Spike kettle; got that ordered today.

I also ordered the element you showed on Amazon; all I need now is the RIMS tube as you spec'd above.

BTW: Do you have a pic that shows how you set yours up? And what are you using to control the BK element?

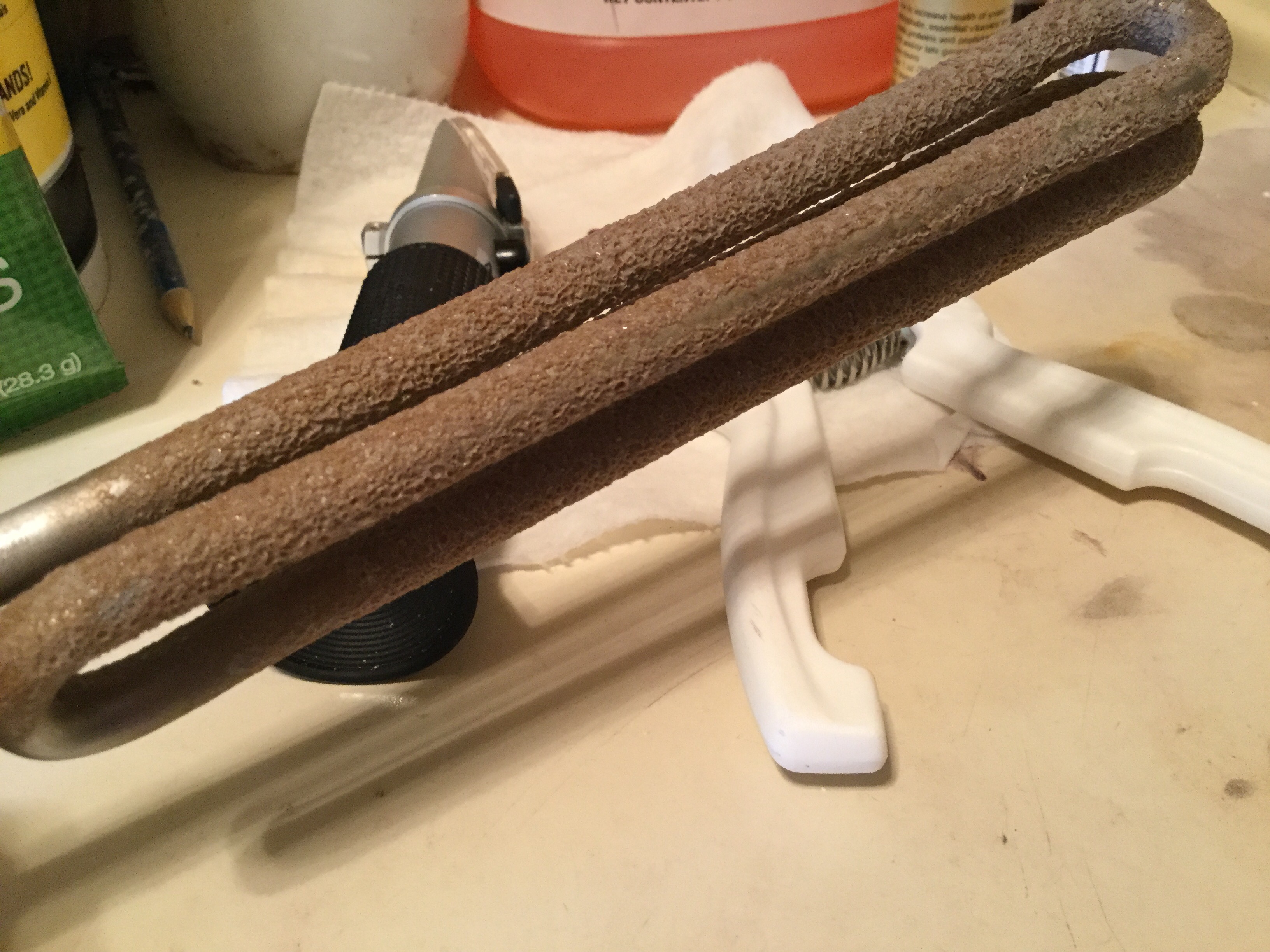

When/if you do put together a RIMS, ensure the element does not make contact with the tube. A little persuasion will line it up (they’re pretty tough so bending it requires some leverage). If it touches it will arc and the wort will burn onto the element creating a tough cleanup job. It doesn’t hurt the wort but it is pretty tough to get off the element. If it does not touch, and flow thru the tube has been maintained while the element is in operation, cleaning is nothing more than disassembly and wiping it off.

![Craft A Brew - Safale S-04 Dry Yeast - Fermentis - English Ale Dry Yeast - For English and American Ales and Hard Apple Ciders - Ingredients for Home Brewing - Beer Making Supplies - [1 Pack]](https://m.media-amazon.com/images/I/41fVGNh6JfL._SL500_.jpg)